Switching devices must be adequately lubricated so they operate smoothly and efficiently as designed. This helps ensure a safe environment for employees working with, on, or near the equipment. Many things must be taken into consideration when selecting a lubricant for electrical equipment. Let’s take a look at some of those factors.

First, the correct type of lubricant must be used. Review the manufacturer’s service manuals, bulletins, and safety data sheets (SDSs) to obtain and use the proper lubricant and apply it to the proper locations. If the lubricant is being applied to electrical parts and equipment that will be energized, it must be appropriately rated for that use.

Will the lubricant be applied manually, such as by using a brush, or sprayed on via an aerosol can or pump sprayer? Common commercial lubricants can be purchased in bulk form for use in a pump sprayer or an aerosol can. Review the service manual and confirm the design and configuration of the equipment being serviced to determine which application method is best.

FLAMMABILITY

If either the material or the propellant is flammable, it cannot be used in an area where heat or a potential arc could ignite it. Review the lubricant’s SDS to determine its flash point. Avoid materials that contain the words “flammable” or “keep away from heat or flames,” feature the Globally Harmonized System (GHS) pictogram (Figure 1) on the label, or contain a propane propellant. These materials typically have a lower explosive limit (LEL), indicating that they will readily ignite in the presence of heat or spark.

STORAGE

Once the correct lubricant for the application has been determined, estimate how much of it will be purchased and stored for future use. The quantity of equipment to be serviced determines the amount of materials needed, and lubricant shelf life and flammable storage limitations must also be considered. Review local and federal fire codes and the SDS for the chemical to determine how much can be safely stored on site. Depending on the chemical’s properties, it may or may not be considered a hazardous or flammable material that requires special storage containment and notification to the local emergency planning commission.

Most petrocarbon-derived chemicals have a shelf life, after which time their effectiveness in lubrication breaks down. If the servicing is done infrequently or in small quantities, it does not make sense to have a large quantity of the lubricant sitting on the shelf for an extended period. Review the SDS to determine shelf life.

If service is performed frequently, or on a large number of similar components, storing hundreds of small aerosol spray cans does not make sense. It may require special storage and disposal considerations, such as a flammable cabinet, due to propane in the aerosol or as the propellant, causing the material to be listed as flammable. In this situation, it may be better to purchase the material in bulk, such as in a 55-gallon container, and use other means to apply it, such as small pump sprayers. This eliminates the propane propellant.

DISPOSAL

The environmental impact of disposing of the chemical should also be considered. Refer to the SDS to identify the environmental impacts of an accidental release. If the substance could pose an environmental hazard upon release, employees must be trained on spill-response procedures for that chemical.

Disposal of lubricant waste can also pose an environmental risk. State and federal agencies such as the Department of Environmental Protection (DEP), the Environmental Protection Agency (EPA), and the Department of Environmental Management (DEM) may require notification when disposing of certain quantities of chemical wastes. There may also be time limitations on the storage of regulated waste chemicals based on certain quantities. Additionally, waste generators, shippers, and disposers are required to obtain certifications and track the shipment of the chemical from cradle to grave.

SAFE HANDLING

Before using any lubricant, check its health effects, flammability, and reactivity. This can sometimes be done by referencing the label, but referencing the SDS is best.

Employee health is a factor when considering an appropriate lubricant. What personal protective equipment (PPE) must the employee wear to apply the lubricant according to the SDS? The technician or electrician may need nitrile gloves and safety glasses or goggles to handle the chemical safely. If the equipment being serviced is enclosed within a cabinet with limited ventilation, fumes and vapors released from using the lubricant can accumulate and possibly overwhelm the employee. This author was involved in an OSHA investigation due to this exact scenario. Always ensure additional ventilation or respiratory protection is provided if required by the SDS. It is important to determine whether the fumes generated from the chemical are denser than air. Dense fumes can collect in low-lying areas and cause a flammable or health-hazardous atmosphere.

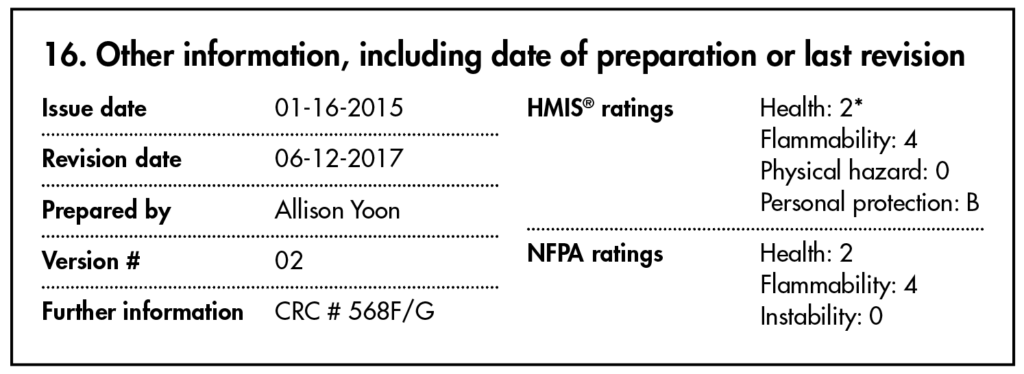

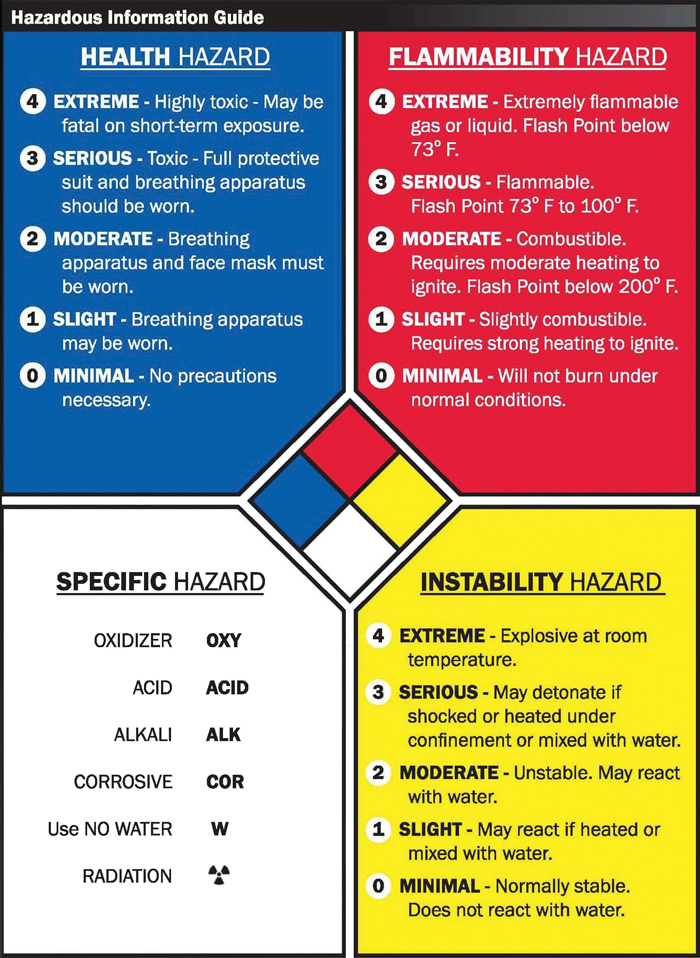

The Hazardous Materials Information System® (HMIS®) is commonly used to determine the hazard level of a chemical. Figure 2 shows the HMIS and NFPA data for a common white lithium aerosol spray lubricant.

Figure 3 shows that this lubricant has very similar ratings under NFPA and HMIS. To understand what those ratings mean, review the detailed rating levels.

Comparing the white lithium grease’s SDS and label and cross-referencing it to the NFPA label shows that the grease has a flash point of less than 73°F and is considered “moderately hazardous” on the health scale. Therefore, this material should not be exposed to an open flame or spark. Additionally, the material has a high enough health rating to warrant concern. By taking proper precautions while using the grease, such as wearing protective gloves (i.e., nitrile), not concentrating and breathing the fumes, and ensuring that it is not exposed directly to open flame, the material is safe enough to use in most cases. Finally, this spray has a propane propellant, so if the material is non-aerosol, the flammability of the material is most likely significantly decreased. If this material is to be used in an area where the possibility of flames or sparks exists, a non-aerosol version would be recommended.

SUMMARY

There are many factors to consider when determining what type of lubricant to use. Most of this information can be quickly obtained from the SDS or label on the chemical container. The SDS for any chemical your company uses must be available to all employees when they are on duty and kept updated per OSHA 29 CFR 1910.1200, Hazard Communication.

Before using a lubricant, review the SDS and label to determine whether the product will be safe for the intended use, what safety precautions may be needed, and which PPE may be required. Review this information with all employees utilizing this chemical to ensure they understand the hazards of its use and how to properly interpret the label and SDS.

REFERENCES

- American Coatings Association. Hazardous Materials Information System®.

- Globally Harmonized System of Classification and Labelling of Chemicals.

- OSHA 29 CFR 1910.1200, Hazard Communication.

- NFPA. NFPA 704–2022, Standard System for the Identification of the Hazards of Materials for Emergency Response.

Paul Chamberlain has been the Safety Manager for Asplundh Electrical Testing, LLC (formerly American Electrical Testing Co., LLC), a subsidiary of Asplundh Engineering Services, LLC since 2009. He has been in the safety field since 1998, working for various companies and industries. Chamberlain received a BS from the Massachusetts Maritime Academy.