This will be the third time since 2011 that we have discussed inadvertent contact with overhead electrical lines. Once in 2011, again in 2017, and now once again in 2025.

Why do we talk about the same subject three times every five years or so? Simply put, we aren’t making enough progress (in my opinion) on this particular electrical hazard.

In 2017, we highlighted two additional reasons why I think this is important, and I think it bears repeating:

- In January 2011, a tragic incident in San Bernardino, California, motivated us to write “Overhead Lines: The Electrical Danger Above,” the Summer 2011 NETA World 70E & NETA column about the dangers of overhead lines. The incident in San Bernardino resulted in the electrocution of three family members: a father (44), a mother (43), and a son (21) who came in contact with a 12-kV overhead line that had fallen in their backyard during a windstorm. From news accounts, it appears as though they went into the yard one-by-one, initially to investigate the problem, then to help each other out….which resulted in three fatalities.

- Unfortunately, things have not improved much since 2011. Contact with overhead lines still statistically leads the pack for electrocution deaths. David Wallis, OSHA’s representative on the 70E technical committee, made an impactful statement years ago at a 70E committee meeting that still resonates today. Paraphrasing, Wallis said, “If someone in this room can come up with a way to reduce the number of overhead line contacts, we at OSHA will take it, because we can’t seem to effectively change the number of incidents that occur each year, and something needs to be done.” Wallis served as the Supervisory Electrical Engineer, Directorate of Standards and Guidance.

Overhead electrical line contact is one of the leading causes of fatal electrical injuries, according to OSHA, with similar data from the U.S. Bureau of Labor Statistics (BLS). Online data from OSHA and BLS consistently show that contact with overhead power lines is among the top three causes of electrocution fatalities in the workplace.

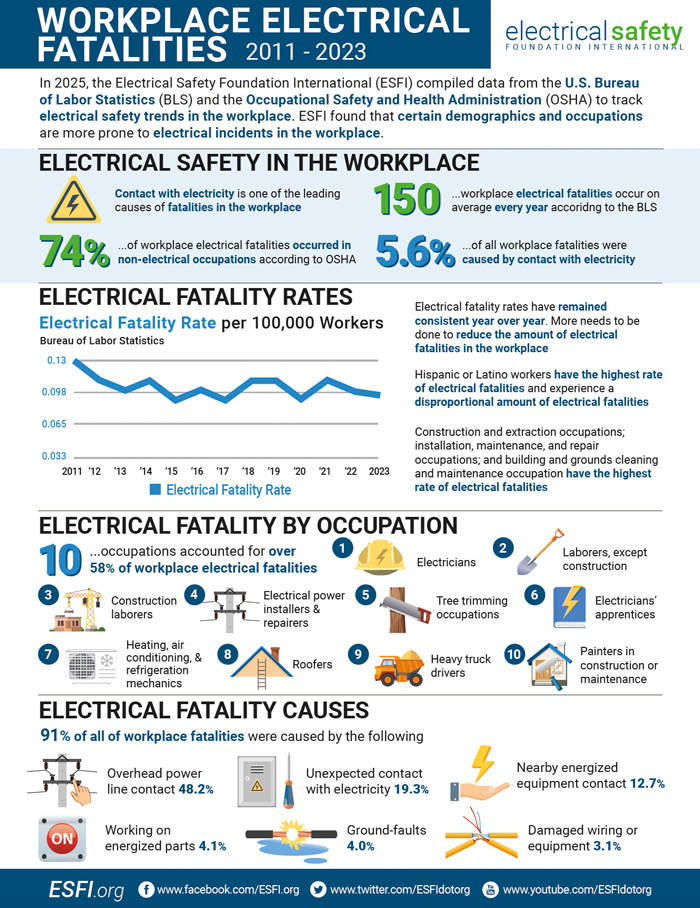

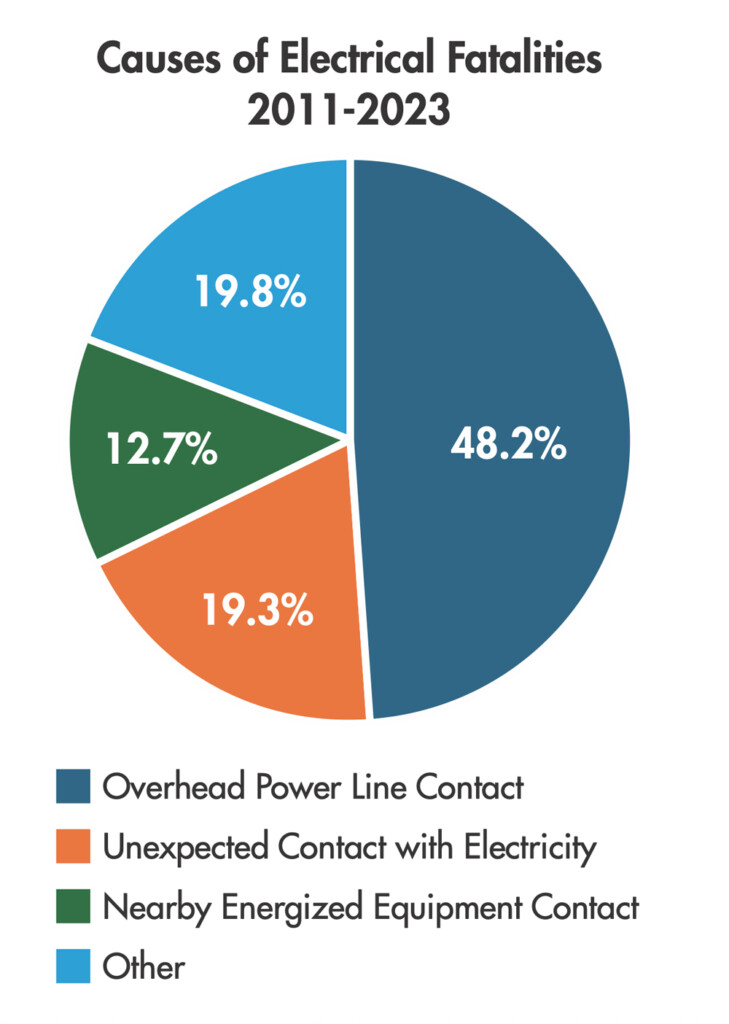

New data compiled by Daniel Majano for the Electrical Safety Foundation International (ESFI) using data from the BLS Census of Fatal Occupational Injuries (CFOI) and the OSHA 170 Forms from 2011–2023, provides great information on workplace injury and fatality statistics. You can find more information here: https://www.esfi.org/workplace-safety/workplace-injury-fatality-statistics/.

The ESFI Report included the following statement:

Overhead power line contact is the leading cause of workplace electrical fatalities. Overhead power line contact accounts for 48.2% of all electrical fatalities, 26% of electrical occupation fatalities, and 57% of non-electrical occupations. Overhead power line contacts are unique because in many cases the fatality occurred when the power line was clearly visible.

As you can also see in ESFI’s reporting (Figure 1), most of the victims (57%) are not electricians, but rather equipment operators, laborers, roofers, and drivers working near energized lines.

SOURCE: ELECTRICAL SAFETY FOUNDATION INTERNATIONAL

all electrical fatality causes are attributed to contact with overhead power lines. Because of that, we electrical workers, who should be trained and qualified in the hazards of overhead lines, should always keep an eye out for non-electrical workers on the job site and take extra steps to warn others about the hazards of overhead lines.

NFPA 70E ANNEX N

Now let’s talk about the assistance we can get from NFPA 70E. In addition to Informative Annex N, Example Industrial Procedure and Policies for Working Near Overhead Electrical Lines and Equipment, three additional sections of NFPA 70E include information related to working on or near overhead lines:

- 120.4(D)(5) Hold card tagout device

- 130.9 Work Within the Limited Approach Boundary or Arc Flash Boundary of Overhead Lines

- 205.16 Overhead Line Clearances

If you take the time to read and implement the policies and procedures detailed in NFPA 70E, and specifically Informative Annex N, you should greatly improve safe work practices when working on or near overhead lines.

The Takeaway

Overhead line safety need not be a guessing game. Make it a training point! NFPA 70E’s Informative Annex N gives you a blueprint for safely working around overhead lines. Within Annex N, you will find guidance on:

- N.2 Developing an Overhead Power Line Policy (OPP)

- N.4 Procedures for the Worksite

- N.4.2 Look Up and Live Flags

- N.4.3 High-Risk Tasks

- Heavy Mobile Equipment

- Aerial Lifts, Cranes, and Boom Devices

- Tree work

- N.4.5 Vehicles with Loads in Excess of 4.25 m (14 ft) in Height

And remember, just because power lines are overhead doesn’t mean they’re out of the way. They’re one of the most dangerous hazards in the workplace — silent, deadly, and often underestimated.

Final Thoughts

Annex N may be labeled as “Informative,” but the lessons it contains are anything but optional. Whether you’re overseeing a crew or working on the front lines, following this guidance can make the difference between going home safe or not going home at all.

Electrical safety starts with awareness. And overhead line awareness starts with Informative Annex N.

Remember — before working on it, turn it off….and Test Before Touch!

REFERENCES

- White, Jim & Widup, Ron. “The 70E & NETA — Overhead Lines: The Electrical Danger Above,” NETA World, Summer 2011, pp. 29–31.

- Majano, Daniel. Workplace Injury & Fatality Statistics, Electrical Safety Foundation International (ESFI), March 23, 2025. Available at https://www.esfi.org/workplace-safety/workplace-injury-fatality-statistics/.

- National Fire Protection Association (NFPA). NFPA 70E®, Standard for Electrical Safety in the Workplace®, 2024 Edition. Available athttps://www.nfpa.org/codes-and-standards/nfpa-70e-standard-development/70e.

Ron Widup is the Vice Chairman, Board of Directors, and Senior Advisor, Technical Services for Shermco Industries and has been with Shermco since 1983. He is a member of the NETA Board of Directors and Standards Review Council; a Principal member of the Technical Committee on Standard for Electrical Safety in the Workplace (NFPA 70E); Principal member of the National Electrical Code (NFPA 70) Code Panel 11; Principal member and Chairman of the Technical Committee on Standard for Competency of Third-Party Evaluation Bodies (NFPA 790); Principal member and Chairman of the Technical Committee on Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation (NFPA 791); a Principal member of the Technical Committee Standard for Electrical Equipment Maintenance (NFPA 70B); and Chair of IEEE Std. P902 (Yellow Book) Recommended Practice for Maintenance and Operational Safety of Electrical Power Distribution Systems in Industrial and Commercial Facilities.He is Chairman of the Texas State Technical College System (TSTC) Board of Regents, a NETA Certified Level 4 Senior Test Technician, State of Texas Journeyman Electrician, a Senior Member of the IEEE Standards Association, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).