The Six-P Rule (Proper Prior Planning Prevents Poor Performance) can go a long way to preventing human error, but humans still make mistakes. James Reason, a prominent University of Manchester professor, psychologist, and author, states:

“Human error is a consequence, not a cause. Errors are shaped by upstream workplace and organizational factors. Only by understanding the context of the error can we hope to limit its reoccurrence.”

Human beings are fallible and make mistakes. Those mistakes are usually caused by only a few factors.

COMMON TRAPS

Traps constantly present themselves when attempting to complete a task. While these traps are contributing factors to an incident, identifying and mitigating them can potentially prevent an incident. Let’s look at some common traps found when performing any task.

Time Pressure

When employees rush, they can have a lapse in judgement. The rush can be caused by external and internal forces.

- External time pressure can occur when a boss, peer, or prime contractor pressures an employee or subcontractor to complete the work quickly. Perhaps they need to move on to another location or task, or maybe a limited outage window has been impacted by some other force (i.e., other contractors eating up outage time).

- Troubleshooting a failed component and repairing or replacing it to re-energize a critical system during an outage window is a prime example of time pressure.

- Another version of time pressure is internal, such as a need to get home at the end of the day or other scheduling conflicts in an individual’s personal life. For example, if an employee’s son is scheduled to pitch his first high school baseball game that evening, the employee might complete his tasks quickly to make it to the game for the first pitch. Rushing through the work can produce mistakes, and those mistakes can lead to incorrectly operating equipment, potential injuries, or worse.

Missing or skipping steps, improper communication, and missing warning signs are just a few of the issues that can occur when rushing.

Mondays and Fridays

On Mondays, some workers may not have fully recovered from a busy weekend. Being tired or not fully engaged in the work can cause mental lapses. On Fridays, a worker might be in a rush to get out the door to start the weekend, causing mental disengagement with the task. Mental disengagement is not exclusive to Mondays and Fridays. It also applies after any prolonged absence from work, such as before and after long weekends, vacations, lay-offs, etc.

No matter where the need to rush comes from, it is always necessary to push back and realize that this time pressure can lead to a mistake. Take the time to slow things down; it is faster to do things right once than to do it incorrectly and need to do it a second time.

Distractions

Being distracted mentally or physically can lead to a lapse of judgment or a missed step. When doing something critical that requires intense awareness, ensure that distractions are kept to a minimum.

Smartphones and tablets are major distractions. Make it a habit to power them down and set them to vibrate or put them elsewhere when doing something critical. Using these devices is an example of a mental as well as a physical distraction.

A change in an employee’s work schedule can contribute to tiredness and dulled senses, and drastic weather changes from hot to cold or vice-versa can also be distractions. Distractions can also come from outside the work environment. Trouble at home, kids getting bad grades, and money issues all contribute to mental distractions that can be detrimental to the work environment.

AVOIDING TRAPS

Many traps can be mitigated using a few simple tricks, and handy everyday tools can help mitigate human fallibility.

Write It Down

- Pen and paper to make notes is a tried-and-true method.

- A laptop and scheduling program offer newer methodologies.

- Developing plans and procedures for the task and writing them down step by step before the work begins helps ensure that the right skills, tools, equipment, and personnel are present for the work.

Hold a Pre-Job Briefing

A pre-job briefing is an effective means of documenting and communicating the steps and hazards of the job. The more complex or unfamiliar a task, the more comprehensive the pre-job briefing must be. Ensure that all people affected by the task attend the pre-job briefing. This can include other contractors not directly involved in the scope of work but who are in or near the work area where the task is being performed.

Communicate Effectively

Ensuring that a message is sent and received properly is critical.

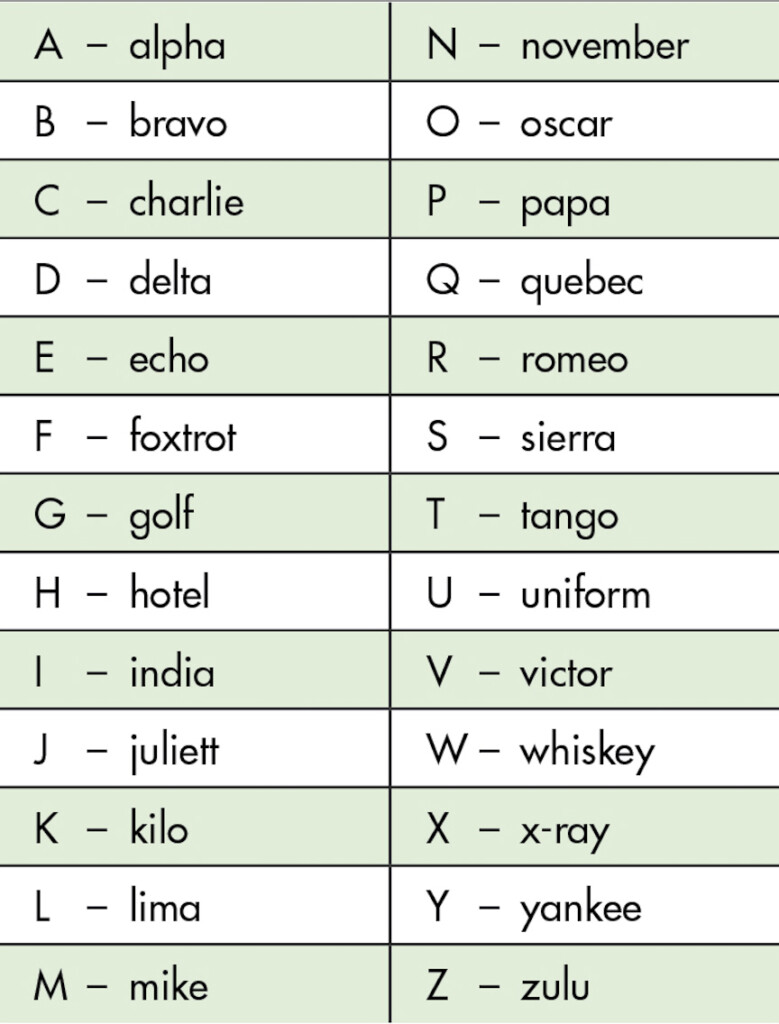

- Use the phonetic alphabet (Figure 1) and numerals when communicating equipment identifications or other nomenclature. This prevents peers and other employees from going to the wrong equipment or potentially using incorrect or misheard settings.

- Using three-part communication when doing critical tasks is always a good idea. Three-part communication ensures that the message sent is the message received. Three-part communication consists of:

- A sender states a direction or information.

- A receiver repeats the information verbatim.

- The sender acknowledges that the information is correct.

- a. If the information is repeated back incorrectly, the sender states that the information is incorrect, and repeats step 1.

As the receiver of information, getting all the information needed to complete the task means everything must be questioned:

- Question why certain test procedures are used.

- Question why a lockout was performed and by whom and when.

- Ensure that the big picture is communicated so that there is an understanding of all aspects of the job.

As the sender of information:

- Ensure that the receiver truly understands what is necessary.

- Over-communicate the steps needed and the results expected.

- Write it down and give notes to the receiver. This ensures complete understanding between work crew members or if work is turned over from one workgroup to another.

Keep Your Place

Placekeeping is used to mark the steps in a procedure or work document that have been completed so that steps are not accidentally omitted or repeated. When suspending a procedure, placekeeping is used to identify the last step completed. Prior to restarting the work, conduct a thorough review of the procedure.

Use Physical Barriers and Visible Cues

Flagging is used to highlight a component to reduce the chances of performing actions on the incorrect component. Operational barriers are used to mark or cover components that are not to be worked on or manipulated during an evolution. Flagging and operational barriers are particularly helpful when there are several similar components near those affected by the work activity. Experience indicates that incidents have resulted from an individual starting an activity on one component, taking a break or becoming otherwise distracted, and returning only to perform work on the wrong component.

COACH AND ACCEPT COACHING

It’s human nature to get distracted or complacent on the job and to deviate from performing the prescribed safe operating procedure. Accidents can occur when well-trained employees working in a well-engineered environment do something they shouldn’t have done or fail to do something they should have. We can identify high-risk situations, verify best-practice behaviors, and coach all employees on how to maintain mindfulness and consistently demonstrate those best-practice behaviors.

The saying “Be your brother’s keeper” is a favorite, and it applies here. Coach employees on how to:

- Speak up when they see a co-worker (or a boss) engaging in unsafe behavior and demonstrate how to correct that behavior without getting into conflict.

- Be willing to discuss and learn from near-miss events.

- Plan and run safety meetings that engage employees and promote safety awareness.

- Function as safety leaders by watching out for themselves and others as they go about their work.

Peer coaching and checking are other ways to mitigate incident potential. When doing a complex task, or one that could result in a bad outcome, use your peers. Get help performing the task to ensure the task is performed correctly. Two brains are always better than one, and four eyes are better than two.

Using three-way communication, have a peer read the procedure while you perform the procedure. Have a peer double-check your calculations before submitting them, and have a peer check your grounds prior to beginning the work. There are many ways to use a peer working directly or indirectly with a task performer to ensure the task is completed safely.

THE BIG PICTURE

All of these human conditions contribute to an individual making an error. The most effective means of reducing error is to be fully engaged in the task at hand. Identify conditions that might be a distraction or contribute to a mistake and eliminate those items from the work task.

Many accidents occur when an employee continues blindly on a task and does not heed the warning signs that occur. When something doesn’t seem right, stop, take a step back to re-evaluate, and ask questions of the team performing the work. Get a peer to help. Find out why things aren’t right and heed those warnings. Be cognizant of any internal problems, acknowledge that they might affect the work, and discuss them with fellow workers. Doing this will help minimize the possibility of a problem occurring.

CONCLUSION

Awareness of all contributing factors — and planning for their mitigation — helps make the work environment safer for all. Everyone makes mistakes, but there are ways to identify and minimize the factors that contribute to those mistakes.

REFERENCES

Reason J. “Human Error: Models and Management.” BMJ. 2000 Mar 18;320(7237):768-70. doi: 10.1136/bmj.320.7237.768. PMID: 10720363; PMCID: PMC1117770.

Paul Chamberlain has been the Safety Manager for Asplundh Electrical Testing, LLC (formerly American Electrical Testing Co., LLC), a subsidiary of Asplundh Engineering Services, LLC since 2009. He has been in the safety field since 1998, working for various companies and industries. Chamberlain received a BS from the Massachusetts Maritime Academy.