Falls from ladders account for 20% of all fatalities and lost-workday injuries in general industry according to Occupational Safety and Health Administration (OSHA) statistics. Ensuring that all ladders meet OSHA and American National Standards Institute (ANSI) standards is critical in mitigating this statistic.

OSHA Regulatory Requirements

OSHA published an update to its walking-working surface rule (Subpart D) for general industry in 2016. Subpart D applies to all general industry workplaces, covers all walking-working surfaces unless specifically excluded, and incorporates advances in technology, industry best practices, and national consensus standards to better address slip, trip, and fall hazards.

OSHA incorporated its previously separate regulations for portable wood ladders, portable metal ladders, and fixed ladders under one comprehensive ladder standard: 29 Code of Federal Regulations (CFR) 1910.23, Ladders, applies to all ladders used in general industry with a few exceptions that are outlined in that CFR.

General Requirements

Under the General Requirements section (29 CFR 1910.23(b)), OSHA addresses proper ladder-climbing technique. It requires that employees always maintain three points of contact when ascending or descending a ladder by:

- Facing the ladder

- Using at least one hand to firmly grasp the ladder

- Not carrying any object or load that could cause them to lose balance and fall

Employers must ensure every employee follows this climbing technique.

The General Requirements also cover the design specifications for rungs and steps used on ladders and stepstools. Except for ladders used in elevator shafts and communication towers, the design for rungs and steps must meet the following criteria:

- Parallel, level, and uniformly spaced when the ladder is in position for use

- Spaced not less than 10 inches and not more than 14 inches apart

- Minimum clear width of 11.5 inches for portable ladders and 16 inches for fixed ladders

- Manhole-entry ladder rungs and steps supported by a manhole opening minimum clear width of nine inches

- Minimum clear width of 8 inches for telecommunication-center rolling ladder rungs and steps

- Minimum clear width of 10.5 inches on step stools

Additional requirements:

- Wooden ladders must not be coated with any material that could obscure structural defects.

- Metal ladders must be made with corrosion-resistant material or protected against corrosion.

- Ladder surfaces must be free of puncture and laceration hazards.

- Ladders must only be used for the purpose for which they were designed.

- Ladders must be inspected before initial use in each work shift and more frequently as necessary to identify any visible defects that could cause employee injury.

- Any ladder with structural or other defects must be immediately tagged “Dangerous: Do Not Use” or with similar language in accordance with 29 CFR 1910.145 and removed from service until repaired in accordance with 29 CFR 1910.22(d) or replaced.

Portable Ladders

Portable ladders, which can be readily moved or carried, usually consist of side rails joined at intervals by steps, rungs, or cleats.

Employers must ensure that portable ladders meet the following requirements.

- Rungs and steps are slip resistant.

- Ladders are equipped with a metal spreader or locking device that securely locks ladder in open position.

- Ladders are not loaded beyond maximum intended load.

- No single-rail ladders are used.

- Ladders are secured to prevent accidental displacement or guarded by a temporary barricade when used in passageways, doorways, or driveways.

- Ladders are secured and stabilized if used on slippery surfaces.

- Ladders are not moved, shifted, or extended while being used.

- Top step and caps of stepladders are not used as steps.

- If used to gain access to upper landing surface, the side rails extend at least 3 feet above the upper landing surface.

- Ladders are not fastened together to provide added length unless designed for such use.

- Ladders are not placed on boxes, barrels, or other unstable bases to obtain added height.

Mobile Ladder Stands and Mobile Ladder Stand Platforms

A mobile ladder stand is a mobile, fixed-height, self-supporting ladder that usually consists of wheels or casters on a rigid base and steps leading to a top step. It may also have handrails and is designed for use by one employee at a time. A mobile ladder stand platform adds one or more standing platforms that are provided with means of access or egress.

Employers must ensure these stands and platforms conform to the following;

- Step width must be at least 16 inches.

- Steps and platforms must be slip-resistant.

- Must support least four times the maximum intended load.

- Wheels or casters under load must support their proportional share of four times the maximum intended load, plus their proportional share of the unit’s weight

- With a top step height of 4 feet or above, must have handrails with a vertical height of 29.5 to 37 inches, measured from the front edge of a step. Removable gates or non-rigid members, such as chains, may be used instead of handrails in special-use applications.

- Maximum work-surface height must not exceed four times the shortest base dimension without additional support. Stabilizing outriggers, counterweights, or comparable means to prevent overturning must be used for greater heights.

- Must have wheels or casters that are equipped with a system to impede horizontal movement when an employee is on it.

- Stand and platform steps must be uniformly spaced and arranged, with a rise of not more than 10 inches and a depth of not less than 7 inches. The slope of the step stringer must be less than 60 degrees as measured from the horizontal.

- When the step spacing and arrangement is not feasible for platforms, stabilized units to prevent overturning with steeper slopes or vertical rung ladders are used.

- Stands with a top step height above 10 feet must have the top step protected on three sides by a handrail with a vertical height of at least 36 inches; top steps of 20 inches or more, front to back; and have a midrail and toeboard. Removable gates or non-rigid members, such as chains, may be used instead of handrails in special-use applications.

- A stand’s standing area must be within the base frame.

- Platforms with a platform height of 4 to 10 feet must have handrails in the platform area with a vertical height of at least 36 inches and midrails. Removable gates or non-rigid members, such as chains, may be used instead of handrails in special-use applications.

- Platforms with a platform height above 10 feet must have guardrails and toeboards on the exposed sides and ends of the platform. Removable gates or non-rigid members, such as chains, may be used instead of guardrails in special-use applications.

Ladder Styles and Types

Ladder styles include:

- Ladder-type step stools

- Portable extension

- Step trestle

- Sectional

- Combination

- Single

- Platform

- Articulating

- Articulating extendable

- Telescoping

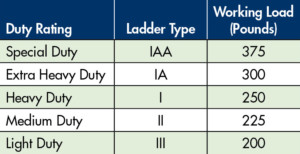

Ladders are rated as follows;

Materials

ANSI is very specific in the design and construction of wood ladders due to the potential defects and types of wood species available. Metal ladder design and construction requirements are minimized because of the wide variety of materials and design possibilities. However, ladders must be of sufficient strength and stiffness to meet performance requirements and must not have any structural defects or hazards such as sharp edges, burrs, etc. Plastic or fiberglass ladders must use fully cured, commercial-grade, thermosetting, polyester resin with glass-fiber reinforcement.

Electrical hazards, temperature extremes, corrosion, outdoor weathering, etc., will help the user determine the proper ladder material.

Proper Use

The proper use of portable ladders includes:

- Select the proper ladder for the job being performed.

- Inspect the ladder to verify proper operation and cleanliness.

- Ensure proper ladder placement so footing and top supports are secure and not creating a traffic hazard for pedestrians.

- Use proper climbing technique.

- Properly care for and store the ladder.

The user must read the manufacturer’s instructions before first use. The user should not use a ladder if sleepy or ill, taking medication, or if there is potential for high wind or lightening. Do not block doorways or other high-traffic areas. Ensure doors are locked and marked with warning signs or cones, and station an attendant at the doorway to keep pedestrian traffic away if possible. Do not use metal ladders near power lines or other sources of electricity to avoid electrical shock hazards. Inspect before use for damage or wear. If a ladder is found to be unsafe for use, remove it from service, and mark it with a “Do Not Use” tag.

Ensure the ladder is proper for the job and that it is properly rated. Ensure it is long enough for the work to be completed safely. Ladder feet should be firmly and evenly planted on the ground. Use boards on soft or uneven ground under the ladder’s feet. Tie off the top of an extension ladder and/or have another person foot the ladder by placing their feet up against the bottom of the rails where the feet contact the ground and placing their hands on a rung at a comfortable height. Rest both rungs of the ladder against the wall or other support. Stepladders must be spread fully and locked into position. Fixed-length and extension ladders must be placed at an angle so they are 1 foot from the wall for every 4 feet of working ladder height.

Make sure hands, shoes, and ladder rungs are dry. Always maintain three points of contact on the ladder (two hands and one foot or one hand and two feet) when ascending or descending. Always face a ladder. Climb slowly. Keep your weight centered between side rails. Do not lean back, and never stand on the top two rungs of a stepladder or top four rungs of an extension ladder.

Ladder-Marking Requirements

Ladders must be marked with size, type and/or duty rating, maximum working length (if extension ladder), highest standing level, total length of sections (if extension ladder), model number or name, manufacturer’s or distributor’s name, manufacturer’s plant location (if multiple plants may be coded), month and year of manufacture, and ANSI compliance and warranty (if applicable). Usage guidelines and other warning statements must also be placed on the ladder in specific locations depending on ladder type.

Conclusion

Ladders have been proven to be a dangerous but necessary tool on the work site. Proper use and maintenance are required to ensure employees remain safe. As with any tool, the user is the last line of defense when it comes to their own safety. Inspect a ladder before use and be knowledgeable in what is required to ensure the ladder is in good condition and is the proper type.

Paul Chamberlain has been the Safety Manager for American Electrical Testing Co. LLC since 2009. He has been in the safety field for the past 17 years, working for various companies and in various industries. He received a BS in safety and environmental protection from Massachusetts Maritime Academy.

Paul Chamberlain has been the Safety Manager for American Electrical Testing Co. LLC since 2009. He has been in the safety field for the past 17 years, working for various companies and in various industries. He received a BS in safety and environmental protection from Massachusetts Maritime Academy.