Transitioning from the year 2022 into 2023 not only turned the page on electrical equipment maintenance but also placed us into a whole new book altogether. Long-standing as a recommended practice, on January 16, 2023, NFPA 70B became the Standard for Electrical Equipment Maintenance.

What does it mean, then, to change from a recommended practice to a standard? The NFPA Glossary of Terms describes a “recommended practice” as a document similar in content and structure to a code or standard but that contains provisions using the word “should” to indicate recommendations in the body of the text. A “standard” contains provisions using the word “shall” to indicate requirements. So, whereas a recommended practice only provides recommendations, a standard provides requirements. A jurisdiction may then use these requirements as a tool for enforcement.

The authority having jurisdiction (AHJ) is commonly responsible for overseeing requirements utilized in their jurisdiction. AHJs are often thought of as local, state, or federal inspectors, and in many cases they are. The definition of “authority having jurisdiction” in the NFPA Glossary of Terms also aligns with the same definition within the 2023 edition of NFPA 70B, which reads:

An organization, office, or individual responsible for enforcing the requirements of a code or standard, or for approving equipment, materials, an installation, or a procedure.

While an inspector certainly meets this definition, it is important to understand that the AHJ could also be someone at the corporate level responsible for enforcing the requirements of a code or standard such as NFPA 70B being utilized. By becoming a standard, NFPA 70B is now an enforceable resource to be used by the AHJ to ensure electrical equipment is properly maintained.

THE HISTORY

Fifty years have passed, and 15 editions have taken us from the initial 1973 NFPA 70B–T, Tentative Recommended Practice for Electrical Equipment Maintenance, to the current 2023 NFPA 70B, Standard for Electrical Equipment Maintenance.

By the mid-1960s, the National Electrical Code (NEC), had spent nearly 70 years as the premier code for electrical safety. As it was updated regularly through the NFPA standards development process, the NEC received regular public input on how to improve the document.

During this time, changes to incorporate requirements for electrical equipment maintenance began to make their way to the National Electrical Code Correlating Committee. While performing due diligence in exploring the proposed changes, the Correlating Committee acknowledged a clear need for guidelines around safe electrical equipment maintenance; however, they determined that the NEC was not the proper code in which to keep those requirements. As a result, NFPA established an ad hoc committee in 1967 to further explore electrical equipment maintenance and determine whether there was a need to develop a document.

(Image courtesy NFPA, www.nfpa.org.)

In June 1968, NFPA officially established the Committee on Electrical Equipment Maintenance to begin developing text around preventative maintenance of electrical systems and equipment to help reduce the loss of lives and property. Five years later, in 1973, the work performed by that committee would lead to the publishing of NFPA 70B–T, Tentative Recommended Practice for Electrical Equipment Maintenance. In 1975, the “tentative” designation was removed, creating the first publication of NFPA 70B, Recommended Practice for Electrical Equipment Maintenance.

Over the years, changes in safety needs and technologies often drive codes and standards to be modified, and the past fifty years for NFPA 70B have been no different. The initial 1973 edition focused primarily on electrical preventative maintenance (EPM) programs: what they are, how to develop one, and why they pay dividends.

The next few editions over the course of the 1970s put more substance into the document that supported specific equipment and processes, even adding specific maintenance intervals and an appendix (now called annex) that provided support for instructing people on how to perform electrical equipment maintenance. The introduction within Appendix C of the 1974 edition of NFPA 70B gave more insight into the intent of the training, stating:

Training is a process for changing behavior. These behavioral changes are the product of new knowledge, reshaped attitudes, replaced skills, and newly acquired skills that express themselves, or become observable, as improved work techniques of the learner.

This language clearly starts setting the table for changing the thought process of electricians and maintenance workers as they consider the necessity for electrical equipment maintenance.

Updates to NFPA 70B in the 1980s through the mid-1990s again centered around adding maintenance recommendations for specific equipment, such as cable tray systems, transformers, and uninterruptable power supply (UPS) systems. New chapters were added covering power system studies, power quality, and vibration analysis pertaining to rotating machinery.

In 1998, maintenance techniques for stationary batteries and infrared inspections were added. More importantly, this edition introduced a significant new topic: worker safety. For the past 25 years, the focus of NFPA 70B was on recommendations that would help maintain electrical equipment safely, but it did not address worker safety. The 1998 edition is where you start to see overlap with NFPA 70E, Standard for Electrical Safety in the Workplace, where safety of the worker is the top priority.

The importance placed on worker safety within NFPA 70B was further proven in the 2006 edition, where Chapter 7 was added specifically for personnel safety. This chapter reiterated the importance of qualified persons performing tasks, risk analysis, and the importance of establishing an electrically safe work condition (ESWC) — a significant page right out of the NFPA 70E playbook.

Much of the change in the 2002 through 2019 editions of NFPA 70B was focused on ensuring the document was structured to meet the requirements of the NFPA Manual of Style but also to begin incorporating technology-specific maintenance recommendations. Innovations in the electrical industry over the previous couple of decades had led NFPA 70B to incorporate chapters on photovoltaic systems, electric vehicle charging systems, wind power electrical systems, and battery maintenance safety. A very practical and useful addition to the 2016 edition of NFPA 70B was torque recommendations to assist in minimizing electrical issues associated with poor connections. Revisions to the 2019 edition of NFPA 70B were mostly editorial and style changes to improve consistency.

The 2023 edition modifications took the recommendations in the 2019 edition and converted the language into requirements, as well as making other necessary adjustments within the document that assisted in making the transition from a recommended practice to a standard, which brings us to where we are now.

NFPA 70B Development Milestones

- Mid 1960s. The National Electrical Code Correlating Committee receives requests to include maintenance recommendations in NFPA 70®, National Electrical Code® (NEC®). The committee recognizes the need but determines that the NEC is not the proper place.

- 1967. NFPA establishes an ad hoc committee on electrical equipment maintenance to determine the need for the development of a document on the subject.

- June 27, 1968. NFPA establishes the Committee on Electrical Equipment Maintenance with the following scope, in part:

To develop suitable texts relating to preventive maintenance of electrical systems and equipment used in industrial-type applications with the view of reducing loss of life and property. - 1973. NFPA 70B–T, Tentative Recommended Practice for Electrical Equipment Maintenance. Chapters cover Why an Electrical Preventive Maintenance (EPM) Program Pays Dividends, What Is an Effective Electrical Preventive Maintenance Program, and Planning and Developing an Electrical Preventive Maintenance Program.

- 1974. NFPA 70B–T is modified to include a chapter on the fundamentals of electrical equipment maintenance, general maintenance requirements for various types of equipment, and a new appendix: How to Instruct.

- 1975. The tentative recommended practice was adopted as NFPA 70B, Recommended Practice for Electrical Equipment Maintenance.

- 1977. Added chapters included Electronic Equipment, Ground-Fault Protection, Wiring Devices, and Maintenance of Electrical Equipment Subject to Long Intervals Between Shutdowns. New appendices addressed NEMA plug and receptacle configurations and guidelines for long-term maintenance.

- 1983. New chapters were added on cable tray systems and on de-energizing and grounding equipment to provide protection for maintenance personnel. An appendix covering equipment storage and maintenance during construction was also added.

- 1987. Requirements for distribution transformers and power transformers were added.

- 1990. A chapter on uninterruptable power supply (UPS) systems was added.

- 1994. Three new chapters covering power system studies, power quality, and vibration analysis pertaining to rotating machinery were added. Other revisions were made to comply with the NFPA Manual of Style.

- 1998. The chapter on power quality was rewritten and expanded. Maintenance techniques for stationary batteries and infrared inspections were updated and revised. Special handling and disposal considerations were introduced, and employee training was focused on emphasizing workplace safety.

- 2002. NFPA 70B was restructured to comply with the Manual of Style for NFPA Technical Committee Documents. The scope was revised to include preventive maintenance for electronic and communications equipment. A chapter was added for grounding maintenance issues. The chapter on power quality was enhanced with information on the latest technology on voltage fluctuation. A new annex suggested maintenance intervals for electrical equipment.

- 2006. Chapters were added on the importance of safety, commissioning electrical systems, and reliability-centered maintenance (RCM).

- 2010. Reorganization was carried out to group like topics and equipment into a more logical arrangement. A chapter was added on testing and test methods to centralize requirements previously found in the individual equipment chapters.

- 2013. Four new chapters were added: Chapter 32 Electrical Disaster Recovery; Chapter 33 Photovoltaic Systems; Chapter 34 Electrical Vehicle Charging Systems; and Chapter 35 Wind Power Electrical Systems and Associated Equipment.

- 2016. Torque recommendations were added to assist in minimizing electrical issues associated with poor connections. Battery testing and maintenance recommendations were enhanced to provide greater detail regarding proper battery testing and safety considerations for persons performing battery maintenance.

- 2019. Several modifications incorporated editorial and stylistic updates to improve the consistency of the document.

- December 27, 2022. NFPA 70B is officially issued as the Standard for Electrical Equipment Maintenance by the NFPA Standards Council, which also set an effective date of January 16, 2023.

- January 16, 2023. NFPA 70B, Standard for Electrical Equipment Maintenance, takes effect, superseding all previous editions, and is also approved as an American National Standard by the American National Standards Institute (ANSI).

THE STANDARD

The 2023 edition of NFPA 70B, Standard for Electrical Equipment Maintenance, has a defined purpose:

…to provide for the practical safeguarding of persons, property, and processes from the risks associated with failure, breakdown, or malfunction and a means to establish a condition of maintenance of electrical equipment and systems for safety and reliability.

This is stated in Chapter 1 Section 1.2 and gives a clear picture of what the standard is intended for. A couple of other sections in Chapter 1 also help bring some clarity around how NFPA 70B is to be used.

- Section 1.3 pertains to application and states that while the standard applies to maintenance for electrical, electronic, and communication systems, it is not intended to duplicate or supersede manufacturers’ instructions. Wherever manufacturers provide specific maintenance instructions for their products, they must be followed.

- Section 1.3 also makes it clear that consumer appliances and equipment intended primarily for use in the home do not fall under the requirements of NFPA 70B.

- Finally, equivalency is covered in Section 1.4, which states that nothing in NFPA 70B “is intended to prevent the use of systems, methods, or devices of equivalent or superior quality, effectiveness, and safety over those prescribed by this standard.”

As a baseline, having a strong understanding of Chapter 1 will help users better apply the requirements found in the rest of the chapters of NFPA 70B.

Chapter 2 addresses referenced publications.

Chapter 3 holds the definitions for NFPA 70B.

Chapter 4 may be titled General but several foundational requirements are found within this chapter. Section 4.2 requires that the equipment owner must implement and document an electrical maintenance program (EMP) that directs activity appropriate to the safety and operation risks. The EMP must identify the principles it is based on and the goals to be achieved, be audited at intervals not exceeding five years, and identify a qualified person as the EMP coordinator who will oversee the program. It must also be designed to work in conjunction with the site electrical safety program (also see NFPA 70E, Standard for Electrical Safety in the Workplace) and, at minimum, include the nine elements specifically listed in Section 4.2.4.2:

- An electrical safety program that addresses the condition of maintenance

- Identification of personnel responsible for implementing each element of the program

- Survey and analysis of electrical equipment and systems to determine maintenance requirements and priorities

- Developed and documented maintenance procedures for equipment

- A plan of inspections, servicing, and suitable tests

- A maintenance, equipment, and personnel documentation and records-retention policy

- A process to prescribe, implement, and document corrective measures based on collected data

- A process for incorporating design for maintainability in electrical installations

- A program review and revision process that considers failures and findings for continuous improvement

Chapter 5 covers personnel safety, requiring that work be performed only by qualified persons and that electrical safety-related work practices that help workers identify hazards and reduce the associated risks must be used. The NFPA 70B definition of a “qualified person” mirrors the same definition in NFPA 70E:

…one who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify the hazards and reduce the associated risks.

It is important to keep in mind, especially when dealing with different types of equipment, that a person may be deemed qualified for one task but may be unqualified for another.

Chapter 6 provides the requirements for system studies and maintaining single-line diagrams that are often critical points of reference for workers.

Chapter 7 and Chapter 8 cover fundamental tests and field testing, respectively.

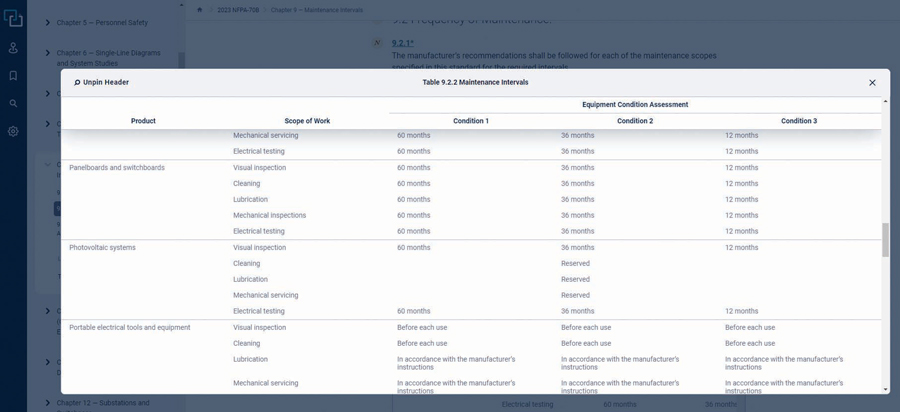

Chapter 9 is perhaps one of the most usable parts of NFPA 70B, as it identifies the required frequency of maintenance for electrical equipment. Much of this chapter is centered around Table 9.2.2, which provides maintenance intervals based on the type of equipment, the scope of work, and the condition of the equipment. Section 9.3 elaborates more on what criteria must be met in order to be classified into each of the three conditions shown in Table 9.2.2.

Several criteria listed within each condition must be met, but a key takeaway that can be used as a base premise is that Condition 1 is for equipment that has been maintained in accordance with the EMP; Condition 2 is for equipment that has had some inconsistencies between maintenance or repairs during the previous maintenance cycle; Condition 3 is for equipment that has missed the last two successive maintenance cycles in accordance with the EMP.

As an example, performing electrical testing on a panelboard that has been maintained in accordance with the EMP means that the work can be done every 60 months. However, performing electrical testing on the same panelboard where the last known maintenance records are two decades old, means that the same work must be done every 12 months.

Chapters 10 through 38 cover requirements around maintenance, visual inspections, and servicing, among other items, specific to the different types of equipment. A wide variety of equipment is covered from timeless equipment such as circuit breakers, fuses, lighting, and wiring devices to newer technologies such as photovoltaic systems, wind power electric systems, battery energy storage systems, and electric vehicle power transfer systems.

Forecasting that additional information will need to be added to NFPA 70B over the next several cycles, the Electrical Equipment Maintenance Committee that oversees the standard has kept several chapters as reserved: Chapter 23 Lighting Control Systems, Chapter 26 Electronic Equipment, Chapter 37 Instrument Transformers, and Chapter 38 Control Power Transformers.

Annexes

Although not an enforceable part of NFPA 70B, the annexes provide loads of valuable information. As an example,

- Annex A has explanatory material that further elaborates on nearly every chapter, including additional tables and visual aids.

- Annex B through Annex G provide checklists, diagrams, and forms to assist in accomplishing the requirements of NFPA 70B.

- Annex H provides information on equipment storage and maintenance during construction.

- Annex I has details around reliability-centered maintenance (RCM).

- Annex J covers power quality.

- Annex K on electrical disaster recovery describes recovery steps for an electrical power system and related equipment that should be followed before and after an electrical disaster event occurs.

- Annex L provides helpful case studies around maintenance failures.

- Annex M provides additional informational references.

It continues to become more apparent that the inaugural edition of NFPA 70B, as a standard, provides a plethora of requirements and information for electrical equipment maintenance that will assist in maintaining a high level of safety for people, property, and processes.

THE IMPACT

After five decades in the making, the shift from a recommended practice to a standard has NFPA 70B poised to make a significant difference in electrical safety around the world. Implementing, properly utilizing, and enforcing NFPA 70B provides businesses and communities the ability to keep people, property, and processes safe from the risks associated with failures, breakdowns, and malfunctions. When electrical equipment is not maintained, people who utilize those machines may get injured, machines could catch on fire causing damage to the building itself, and critical processes in production can be interrupted, in turn costing companies millions in lost revenue. Maintaining electrical equipment and systems is crucial to safety, longevity, and reliability.

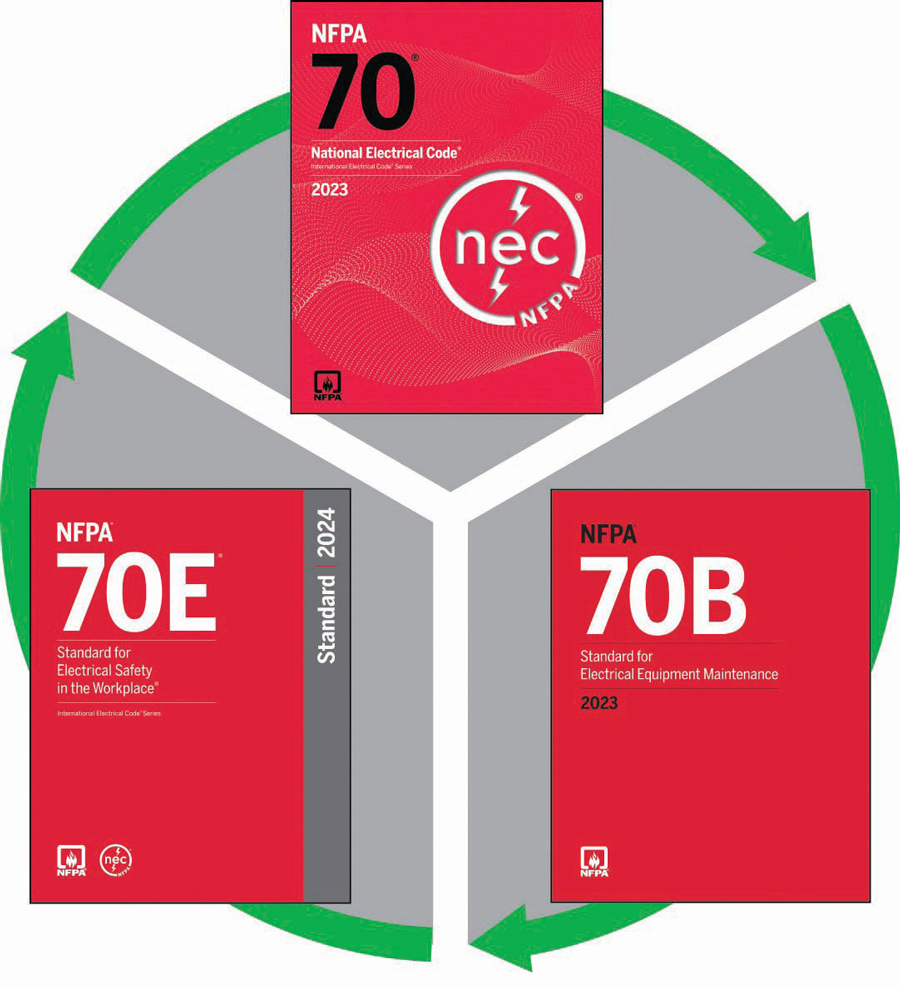

NFPA 70B has become the maintenance component that can now be enforced. NFPA 70, National Electrical Code (NEC), is the answer to safe electrical installations, and NFPA 70E, Standard for Electrical Safety in the Workplace provides safe electrical work practices for employees. Together, these three documents create an electrical cycle of safety where each document is as important as the next when it comes to achieving overall electrical safety.

Some very clear requirements are written into the documents, where one is dependent on another to be in compliance. For example, NFPA 70B Section 4.2.2.1 states that the electrical maintenance program (EMP) must “include elements to verify that electrical equipment or systems have been inspected to comply with applicable installation codes and standards.” The NEC is the means by which electrical equipment and systems can be installed and inspected for compliance. The first element required to be included in EMP, according to NFPA 70B Section 4.2.4.2, is “an electrical safety program that addresses the condition of maintenance,” which would be derived from NFPA 70E. NFPA 70E, in turn, requires any electrical safety program to include elements that consider the condition of maintenance of electrical equipment and systems. NFPA 70B is the means by which a proper condition of maintenance can be achieved. All three of these documents depend on one another to achieve electrical safety.

(Image courtesy of NFPA, www.nfpa.org.)

CLOSING THOUGHTS

As we close the door on NFPA 70B the recommended practice, we open the door to NFPA 70B the standard. Beyond that door lies much opportunity to improve electrical safety for the world. Over 50 years ago, it was people like many of you who proposed the ideas that became NFPA 70B, and it will be people like you who move it forward, for the better, by understanding, implementing, and where necessary, modifying NFPA 70B to keep electrical equipment and systems properly maintained, reliable, and in safe working order.

It will take all of us working together to ensure that, in our time, the world becomes better from an electrical safety perspective. Before his passing in 1990, Muppets creator Jim Henson stated, “My hope is to leave the world a bit better than when I got here.” Me, too, Jim…me, too.

Although the 2023 edition of NFPA 70B just became effective in January, the NFPA Standards Development Process marches on. Public input for the 2026 edition of NFPA 70B is now open and will close on January 4, 2024. To submit a public input for the 2026 edition of NFPA 70B, please visit the Next Edition tab of the NFPA 70B document information page (www.nfpa.org/70B).

Corey Hannahs is a Senior Electrical Content Specialist at the National Fire Protection Association (NFPA). In his current role, he serves as an electrical subject matter expert in the development of products and services that support NFPA documents and stakeholders. Corey is a third-generation electrician, holding licenses as a master electrician, contractor, inspector, and plan reviewer in the state of Michigan. Having previously held roles as an installer, owner, and executive, he has also provided electrical apprenticeship instruction for over 15 years. Corey was twice appointed to the State of Michigan’s Electrical Administrative Board by former Governor Rick Snyder, and he received United States Special Congressional Recognition for founding the B.O.P. (Building Opportunities for People) Program, which teaches construction skills to homeless and underprivileged individuals.

Important Notice: Any opinion expressed in this column is the personal opinion of the author and does not necessarily represent the official position of NFPA or its technical committees. In addition, this piece is neither intended, nor should it be relied upon, to provide professional consultation or services.