In this issue of NETA World, we begin to explain some of the major changes in the 2021 edition of NFPA 70E. So whether you love the 70E, or find it a challenge and don’t want to deal with it…because your life at work is mandated by it, and you know what that means: Do it or else!

But that is not the case. NFPA 70E is a standard and is not mandatory. However, your company has the option of making parts of it their policy, which would then be mandatory for you. Companies often adopt all or part of the 70E because the 70E Committee includes representatives from 26 companies, including NETA, in the formation of the content for the standard, and it contains the latest thinking and information available concerning electrical safety and safe work practice. Your company wants you to go home to your family uninjured. NFPA 70E only covers electrical safety and nothing else.

So familiarize yourself with the latest changes to the 2021 edition of the 70E. Here are a few of the changes.

Article 100

There are very few revisions in Article 100, Definitions. Let’s start with a definition that has not changed: Arc Rating. The important portion of the definition is in Informational Note No. 1:

- Informational Note No. 1: Arc-rated clothing or equipment indicates that it has been tested for exposure to an electric arc. Flame resistant clothing without an arc rating has not been tested for exposure to an electric arc. All arc-rated clothing is also flame-resistant.

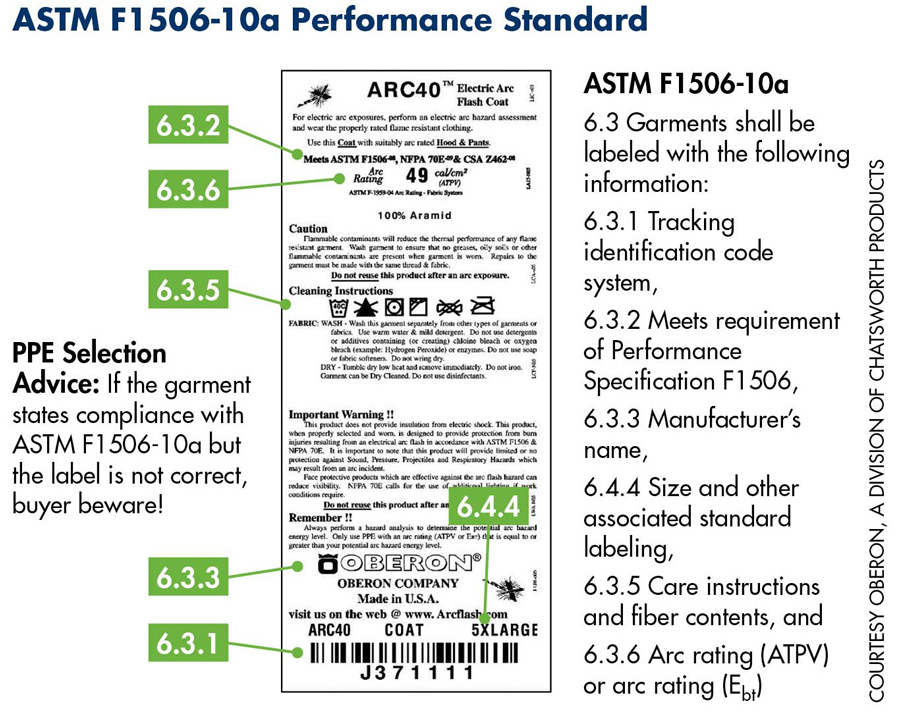

Some technicians or purchasing agents have purchased the incorrect clothing, thinking it was arc rated, only to find out it is for flash fires (refineries and pipelines). Clothing and PPE rated for an arc flash has a tag on the inside of the clothing similar to Figure 1, which is from Oberon, a major supplier of arc-rated clothing and PPE.

Figure 1: ASTM F1506-Required Label

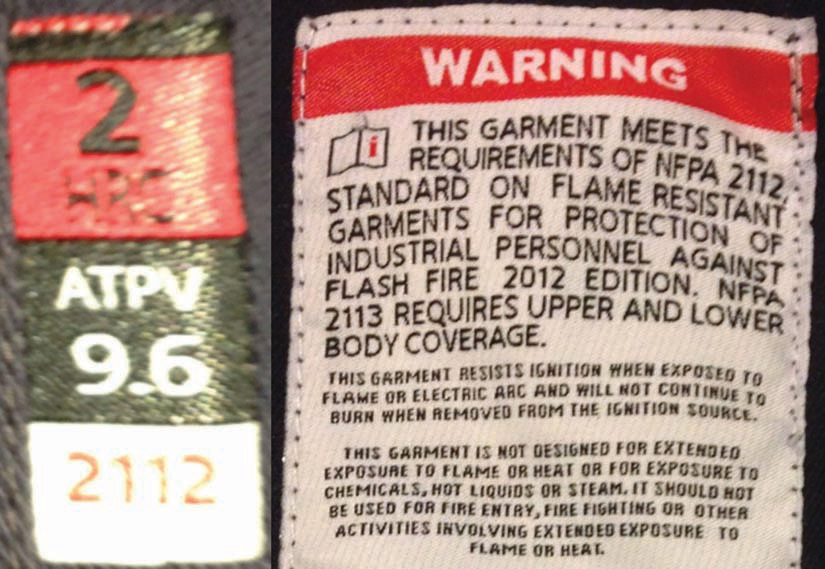

The familiar tag in Figure 2 causes some confusion, since it seems to be for arc-rated clothing; it even shows an arc thermal performance value (ATPV). The tag references NFPA 2112, which is a valid standard, but not for arc-rated clothing or PPE. NFPA 2112 is for flash fires, and that type of clothing is required for petrochemical facilities. This clothing, if properly marked, could be dual-rated as arc-rated and for flash fires, but both would need to be shown on the label.

Figure 2: Confusing Label — Not Arc-Rated

Look for these numbers when purchasing clothing or PPE:

- NFPA 70E, of course

- NFPA 2112: flash fires only

- ASTM F1506: arc-rated clothing always marked with ASTM F1506, may also be marked ASTM F1509/F1509M, and be dual-rated with NFPA 2112 if properly marked

- ASTM F2178/2178M: arc-rated face shields, balaclavas, and hoods

- ASTM F1891: arc-rated rainwear

- ASTM F2675/2675M: arc-rated hand protection

- CSA Z462: Canada’s NFPA 70E-equivalent standard

Definition Revisions

Revisions to NFPA 70E are shown in legislative text: Deleted language is shown in red and crossed through, and added text is shown underlined. All definitions are in Article 100, Definitions.

Deleted. The definitions for Accessible, Readily Accessible, and Branch Circuit were deleted. None were used in NFPA 70E.

Arc Rating. Although the definition for arc rating did not change, revisions were made to the Informational Notes to make them consistent with ASTM language and to provide clarity:

• The previous content in Informational Note No. 2 was moved to Informational Note No. 3: Breakopen is a material response evidenced by the formation of one or more holes in the innermost layer of arc-rated material that would allow flame to pass through the material.

• Informational Note No. 2: ATPV is defined in ASTM F1959/F1959M, Standard Test Method for Determining the Arc Rating of Materials for Clothing, as the incident energy (cal/cm2) on a material or a multilayer system of materials that results in a 50% probability that sufficient heat transfer through the tested specimen is predicted to cause the onset of a second degree skin burn injury based on the Stoll curve.

• Informational Note No. 3: EBT is defined in ASTM F1959/F1959M, Standard Test Method for Determining the Arc Rating of Materials for Clothing, as the incident energy (cal/cm2) on a material or a material system that results in a 50 percent probability of breakopen. Breakopen is defined as a hole with a material response evidenced by the formation of one or more holes of a defined size [an area of 1.6 cm2 (0.5 in.2) or an opening of 2.5 cm (1.0 in.) in any dimension] in the innermost layer of arc-rated material that would allow thermal energy to pass through the material.

Balaclava. (Sock Hood): An arc-rated hood head-protective fabric that protects the neck and head except for a small portion of the facial area of the eyes and nose.

Informational Note: Some balaclava designs protect the neck and head area except for the eyes while others leave the eyes and nose area unprotected.

Figure 3 shows a typical balaclava. Note that a properly fitted balaclava will not be tight, but will fit loosely, as shown. A tight-fitting balaclava will reduce the arc rating. Many companies we’ve visited had only one balaclava for all their qualified persons. This is incorrect and places their workers at risk.

Figure 3: Balaclava and Arc-Rated Face Shield

Not all balaclavas are arc-rated. A balaclava is any type of head covering that has an opening for the face and/or eyes. A ski mask is considered a type of balaclava. A visit to any of the Internet providers will show a wide variety of balaclavas that are not arc-rated, but wool. Wool would be fuel for the fire.

Barrier. A physical obstruction that is intended to prevent contact with equipment or energized electrical conductors and circuit parts or to prevent unauthorized access to a work area. The Committee believed the last portion of the definition was unnecessary.

Electrically Safe Work Condition. An Informational Note was added for Electrically Safe Work Condition.

- Informational Note: An electrically safe work condition is not a procedure, it is a state wherein all hazardous electrical conductors or circuit parts to which a worker might be exposed are maintained in a de-energized state for the purpose of temporarily eliminating electrical hazards for the period of time for which the state is maintained.

Informational Notes are not mandatory but contain information directly related to whatever it may be part of. This Informational Note states that putting equipment into an electrically safe work condition is not a procedure; it is a process, which is on-going. The purpose is to maintain a de-energized state to protect the worker. The word “temporary” and the phrase “for the period of time for which the state is maintained” were added to emphasize that this is not a permanent change; it is only in effect during the task being performed and will be returned to its normal, energized state.

This is Second Revision language. In the First Revision, the language was somewhat different. This type of revision happens often during the meetings. A change will be made during the First Revision; then, a Public Comment will come in and a change will be voted to make further revisions in the Second Revision.

Fault Current Available. An additional Informational Note No. 3 was added to the definition for Fault Current, Available:

- Informational Note No. 3: The available fault current varies at different locations within the system due to the location of sources and system impedances.

Of course, any impedances in the path of the fault current will reduce it, sometimes by quite a bit. It depends on the impedance.

Receptacle. A receptacle is a contact device installed at the outlet for the connection of an attachment plug, or for the direct connection of electrical utilization equipment designed to mate with the corresponding contact device. A single receptacle is a single contact device with no other contact device on the same yoke. A multiple receptacle is two or more contact devices on the same yoke. [70:100]

When a definition is used in the NEC (NFPA 70), it will be noted at the end of that definition as [70:100] where 100 is the NEC Article it will appear in.

Switchgear Equipment, Arc-Resistant. Equipment designed to withstand the effects of an internal arcing fault and that directs the internally released energy away from the employee.

A number of revisions were made to this definition. First, the name was changed to acknowledge that more types of arc-rated equipment are being manufactured.

Two new Informational Notes provide where to obtain more information.

- Informational Note No. 1: An example of a standard that provides information for arc-resistant equipment is IEEE C37.20.7, Guide for Testing Switchgear Rated Up to 52 kV for Internal Arcing Faults.

- Informational Note No. 2: See O.2.4 (9) for information on arc-resistant equipment.

Voltage, Nominal. A new Informational Note was added to this definition.

- Informational Note No. 3: Certain battery units are rated at nominal 48 volts dc but have a charging float voltage up to 58 volts. In dc applications, 60 volts is used to cover the entire range of float voltages.

Pretty self-explanatory, although note that OSHA considers 50 volts and above as an electrical hazard. OSHA has stated they will not accept higher voltages, even if they are in a standard.

Working on Electrical Conductors or Circuit Parts. Intentionally coming in contact with energized electrical conductors or circuit parts with the hands, feet, or other body parts, with tools, probes, or with test equipment, regardless of the personal protective equipment (PPE) a person is wearing. There are two categories of “working on”: Diagnostic (testing) is taking readings or measurements of electrical equipment, conductors, or circuit parts with approved test equipment that does not require making any physical change to the electrical equipment, conductors, or circuit parts. repair Repair is any physical alteration of electrical equipment, conductors, or circuit parts (such as making or tightening connections, removing or replacing components, etc.).

There are no major revisions to this definition, except to separate the two categories of “working on” — diagnostic (testing) and repair — to clarify their differences. It is worthwhile to mention that any change to a piece of equipment, even tightening screws on a terminal block, would be considered repair. This is brought up because some supervisors and technicians don’t believe that tightening screws is repair. Use this simple method to separate diagnostics from repair; If only a test instrument is used, it is diagnostic. If a tool is being used, it is repair.

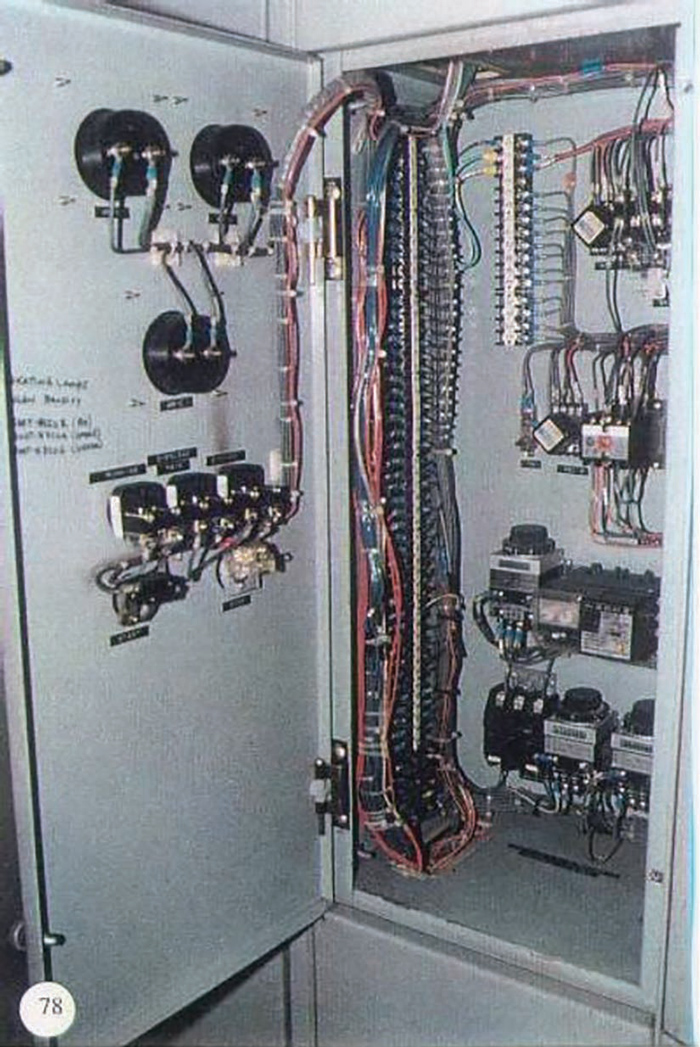

Figure 4a and Figure 4b show an event caused by this misunderstanding of the definition. The supervisor had to leave for another part of the job. The apprentice technician was told only to tighten things “that were not hot.” The apprentice mistakenly used a 1,000-volt-rated tester to test a 4,160-volt potential transformer (PT) to see if it was energized. Things did not go well, and the apprentice suffered serious burns.

Figure 4a: What He Tested

Figure 4b: What He Should Have Tested

A Little Reorganization, Again

NFPA 70E again reorganized to make 70E easier to use and to place information in its proper place.

Article 110 includes some major changes:

- 110.1 Priority (used to be 105.4)

- 110.2 General [used to be 120.2(A)]

- 110.3 (used to be 130.2) Electrically Safe Work Condition

- 110.4 [used to be 130.2(A)] Energized Work

- 110.5(A) (used to be 110.1) Electrical Safety Program

- 110.6 (used to be 110.2) Training Requirements

- 110.7 (used to be 110.3) Host and Contract Employer’s Responsibilities

- 110.8 [used to be 110.4(A)] Testing Instruments and Equipment

- 110.9 (used to be 110.5) Portable Cord- and Plug-Connected Equipment

- 110.10 (used to be 110.6) Ground-Fault Circuit-Interrupter (GFCI) Protection

- 110.11 (used to be 110.7) Overcurrent Protection Modification.

- 110.12 (new) Equipment Use

Article 130 also saw some major re-organizational changes:

- 130.1 General

- 130.2 Energized Electrical Work Permit

- 130.3 Open

- 130.4 Shock Risk Assessment

- 130.5 Arc Flash Risk Assessment

- 130.6 Open

- 130.7 Personal and Other Protective Equipment

- 130.8 Other Precautions for Personnel Activities

- 130.9 Work Within the Limited Approach Boundary or Arc Flash Boundary of Overhead Lines

- 130.10 Underground Electrical Lines and Equipment

- 130.11 Cutting and Drilling

- 130.12 Cutting, Removing or Rerouting of Conductors

At this point, NFPA staff could leave 130.3 and 130.6 open, or they could decide to renumber the entire article(s). The NFPA Manual of Style allows articles to be left open for future use. The only way to be sure is to view the actual 2021 70E. Readers will have to do what everyone else will do: Wait and see.

Deep Dive. Section 110.1 Priority was moved from Article 105 to bring more prevalence to it. The Committee believed it was a better fit in 110, as we did with the other changes in section order. Some changes were made to its Informational Note:

-

- Section 110.1 Priority

Hazard elimination shall be the first priority in the implementation of safety-related work practices. - Informational Note No. 2: An electrically safe work condition is a state wherein all hazardous electrical conductors or circuit parts to which a worker might be exposed are placed and maintained in a

zero-energyde-energized state, for the purpose of temporarily eliminating electrical hazards. See Article 120 for requirements to establish an electrically safe work condition for the period of time for which the state is maintained. See Informative Annex F for information regarding the hierarchy of risk control and hazard elimination.

- Section 110.1 Priority

Committee Statement

An example of a Committee statement is shown below. This is not done for every revision; it is only shown as an example of how the Committee justifies the revisions made.

This second revision improves clarity in the informational note by replacing the undefined term “zero energy” with the defined term “de-energized.” In addition, language is added to clarify that elimination is achieved by disconnecting and isolating from energy sources all electrical conductors or circuit parts to which a worker might be exposed in the area where work is to take place. Additionally, it is clarified that this de-energization is a temporary state and exists only during the period for which the electrically safe work condition state is maintained. This informational note correlates with the purpose of NFPA 70E which is to provide a “practical” safe working area for employees relative to the hazards arising from the use of electricity.

Some of the revisions being made are from the First Revision based on Public Comments or Committee discussions. This is a fairly common occurrence and demonstrates the thought (and discussions) that go into all Public Inputs and Public Comments. We always have a reason for a revision. It isn’t done on a whim or without thought and discussion.

The Second Revision version of NFPA 70E and all Committee Statements are available on www.NFPA.org/70E/nextedition. The First Revision is only available during the Public Comment period. People ask why the Committee takes some action, and the comments are there to answer that question.

Conclusion

This column has tried to explain some of the workings of the NFPA 70E Committee. The work is certainly not taken lightly by the Committee members. We make all efforts to ensure the 70E is easier to use, clearer on its intent, and contains the most effective safety requirements.

The changes made to the 2021 edition on NFPA 70E are not as far-reaching as those in the 2015 and 2018 editions. The above revisions and their explanations are only the beginning of this series of columns explaining the revisions made for the 2021 edition. Some of the changes are covered in this article. Part 2 in the Spring 2021 issue will cover additional detail, and more information will be presented in this ongoing series of 70E & NETA columns. We hope this is helpful to all our readers, many of whom depend on NFPA 70E for their jobs.

We hope it helps the field technicians, owners, and supervisors of both NETA accredited companies and non-NETA entities understand and interpret NFPA 70E better. Following the requirements of the 70E, whether mandated or not, will prevent injuries and possible fatalities.

References

Joseph J. Andrews, PE. “Case History — Who’s at Fault?” Electrical Safety Resources, Inc. IEEE Electrical Safety Workshop 2002.

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E, Electrical Safety Requirements for Employee Workplaces. Both gentlemen are employed by Shermco Industries in Dallas, Texas, a NETA Accredited Company.

Ron Widup, Senior Advisor, Technical Services and Vice Chairman of the Board of Directors, has been with Shermco Industries since 1983. He is a member of Technical Committee on NFPA 70E, Electrical Safety in the Workplace; a Principal Member of National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation; a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron also serves on NETA’s board of directors and Standards Review Council. He is a NETA Certified Level 4 Senior Test Technician, a State of Texas Journeyman Electrician, an IEEE Standards Association member, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

Ron Widup, Senior Advisor, Technical Services and Vice Chairman of the Board of Directors, has been with Shermco Industries since 1983. He is a member of Technical Committee on NFPA 70E, Electrical Safety in the Workplace; a Principal Member of National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation; a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron also serves on NETA’s board of directors and Standards Review Council. He is a NETA Certified Level 4 Senior Test Technician, a State of Texas Journeyman Electrician, an IEEE Standards Association member, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.