May 2020 was a difficult month for our nation, and 2020 is certainly shaping up to be a difficult year. As essential service providers, many in our industry were called upon to maintain or continue building the nation’s infrastructure. We all understand and appreciate that hospitals, emergency services, government facilities, manufacturing, and even residences could not function without power, and NETA technicians across the country stepped up to ensure reliable power was, as usual, taken for granted. Thank you, NETA Technicians!

This article explores a few technologies that are useful for commissioning utility-scale renewable generation plants that were successfully used during the midst of the pandemic.

Six dedicated technicians scattered throughout the United States found themselves driving to a job site as airlines shut down or site-specific rules required a 14-day isolation period if mass travel transportation was used. Technicians from Dallas, Houston, Atlanta, Los Angeles, and Washington DC converged on a remote area in West Texas that recently became more remote due to mandatory or voluntary business closures. Their task was to use infrared and partial discharge technologies to detect conductor and insulation defects that could lead to future unwanted failures at a 200 MW solar facility.

Partial Discharge

On-line partial discharge testing has been the focus of many previous NETA World articles and has proven to be a very good technique for detecting insulation defects in medium-voltage cable systems, switchgear, transformers, and other apparatus while the equipment remains in service. Specialized sensors are temporarily connected safely to grounded components to decouple the electromagnetic signals associated with the discharges, and sophisticated software is used to process the raw signals and remove noise using complex algorithms to assess insulation condition.

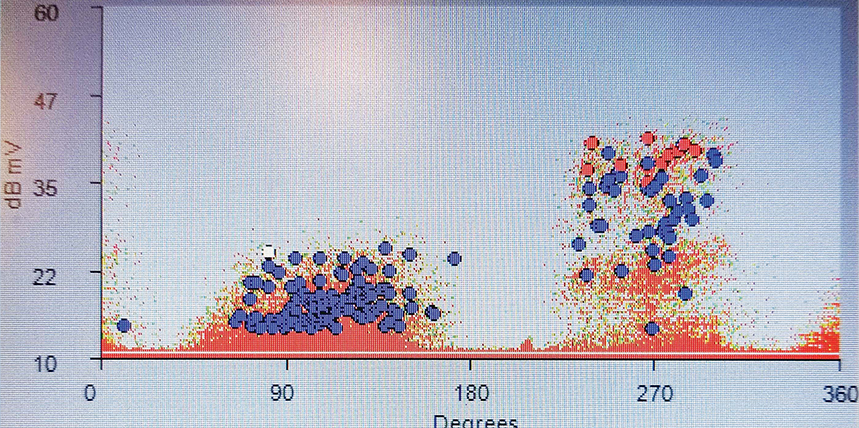

At renewable installations, this technology is capable of detecting insulation defects in cable, cable terminations, and apparatus connected to the cables including switches, circuit breakers, and transformers. One additional bonus for using online partial discharge technology is that it can readily discover loose medium-voltage connections, as the minor arcing that results creates readily detectable high-magnitude electromagnetic signals long before the problem can escalate to become distinguishable as a thermal defect that infrared technology can detect. Figure 1 displays the signal associated with this initially minor arcing phenomenon. For these reasons, online partial discharge testing can be an excellent tool for commissioning medium voltage renewable installations and should be considered for commissioning any type of medium-voltage systems.

Figure 1: Electromagnetic Signal from Minor 34.5 kV Arcing

Infrared

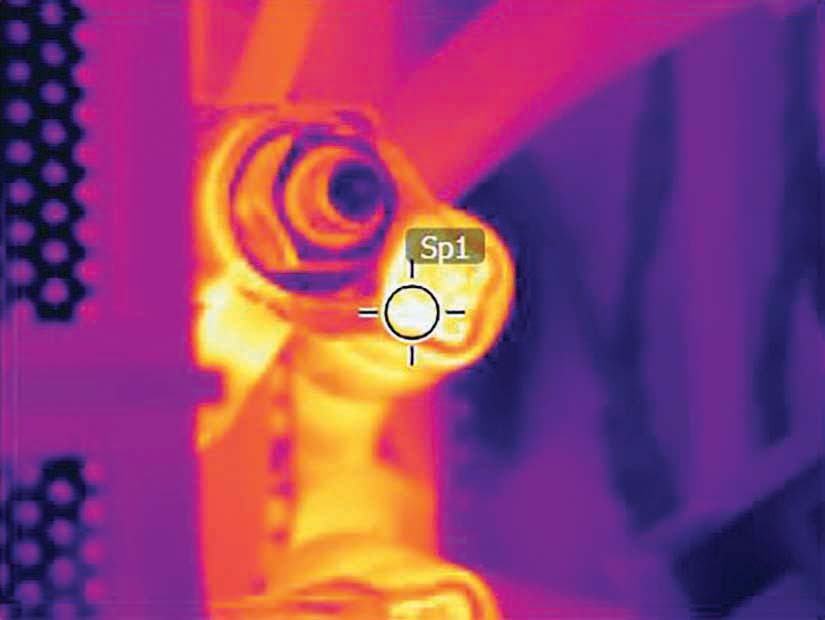

Infrared thermography has been regularly used for decades to detect conductor overheating and is the most widely used online tool second only to voltage and current indicating or sensing instruments. This technology provides thermal images of connections so that elevated temperatures are readily apparent. Actions can then be taken to rectify the problem before complete failure occurs. Figure 2 displays a typical connection problem.

Figure 2: Infrared Detects Loose Low-Voltage Connection

At renewable installations, infrared techniques have proven valuable to detect conductor problems at the hundreds or even thousands of DC wire and cable connections and inverter bus connections. Another valuable application for infrared imaging at solar facilities is to inspect the PV panels themselves for functionality. Nonfunctional panels will not generate power, and defects can range from open conductors, open connectors, or damage to the panel itself. Although solar panel thermal imaging can be performed on foot, using specialized drones equipped with infrared cameras has proven to be much more efficient at large installations.

Drones

Unmanned aircraft systems (UAS) or drone usage has grown astronomically in recent years since it proved advantageous in a broad range of applications from construction to defense to social distancing. Combining infrared technologies with drone use is a relatively new application that has already provided significant cost savings and safety benefits over conventional inspection techniques. Studies have shown that as much as 50% cost savings can be achieved by using drone technologies for PV panel inspections.

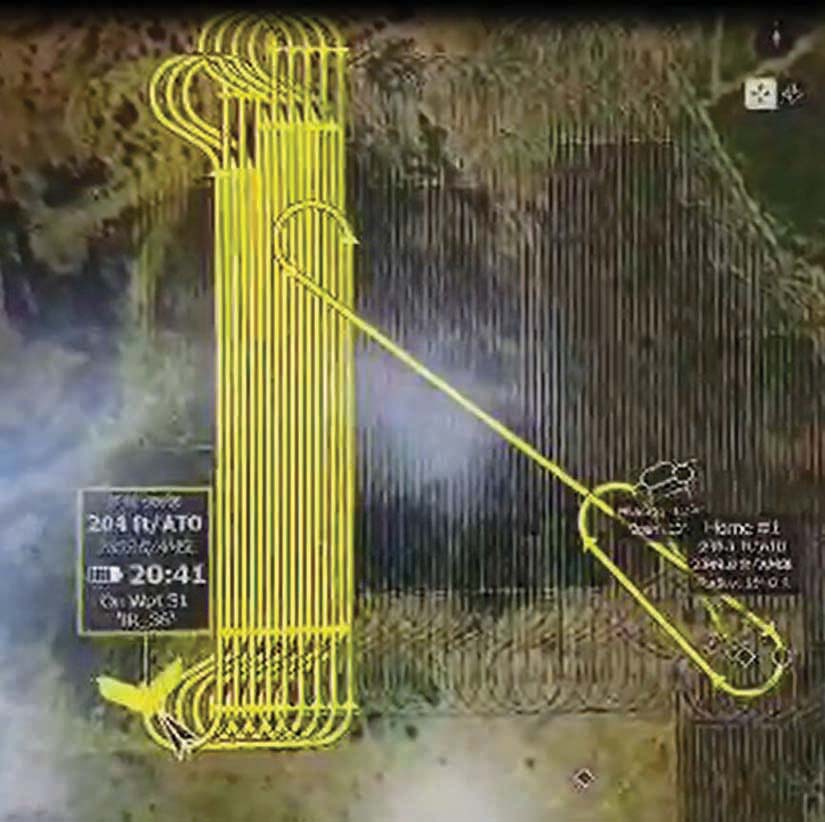

Utility-scale solar sites typically required very-fast, fixed-wing aerial hardware to efficiently weave back and forth along the countless rows of panels to collect infrared data (Figure 3). To maximize field efficiency, flight plans are preprogrammed and loaded into the hardware.

Figure 3: Drone Flight Pattern

Drones fly at high altitudes to map large areas by taking hundreds of infrared images that are then analyzed and compiled into a cloud-based report of deficiencies that consists of anomalies such as those displayed in Figure 4. The report includes GPS coordinates and the physical description and location of the anomalies so the problem can be expeditiously remediated.

Figure 4: Open Inverter String

Spaghetti Dinner

On one particularly comfortable May evening in West Texas, an unlikely group of a half-dozen technicians were pleasantly surprised by a thoughtful senior technician who took it upon himself to prepare a full-on spaghetti dinner. The team sat together on green picnic tables at the rear of the motel property but spaced themselves properly to abide by social distancing guidelines. The sky was silent — no aircraft flew above — reminding them of the weeks after the 9/11 crisis and making them all wonder which way the world will turn tomorrow. Soon, the air was filled with colorful and perhaps slightly exaggerated war stories plus the sweet smell of garlic. A few cans of beers were cracked open leading to peaceful camaraderie and a welcome escape from these stressful times. That evening, the faint sound of the Marshall Tucker Band playing “This Old Cowboy” could be heard in the distance from some cheap radio as the group ate the “best” spaghetti dinner they ever had.

Don A. Genutis presently serves as President of Halco Testing Services, Inc., a NETA Accredited Company with offices in Los Angeles and Houston. He has held various principal positions during his 35-plus year career in the electrical testing field, primarily focused on advancing no-outage testing techniques for the last 20 years, with emphasis on cable and switchgear on-line partial discharge testing techniques. Early in his career, Don acquired and operated the former Westinghouse East Pittsburgh Insulation Research Laboratory, where he gained valuable experience in understanding insulation material performance. Don holds a BS in electrical engineering from Carnegie Mellon University and is a NETA Certified Technician. Don has authored 50 technical articles for NETA World and has been featured in EC&M and Uptime magazines. Don’s work is summarized in his book, Partial Discharge & Other No-Outage Testing Methods, published in 2019.

Don A. Genutis presently serves as President of Halco Testing Services, Inc., a NETA Accredited Company with offices in Los Angeles and Houston. He has held various principal positions during his 35-plus year career in the electrical testing field, primarily focused on advancing no-outage testing techniques for the last 20 years, with emphasis on cable and switchgear on-line partial discharge testing techniques. Early in his career, Don acquired and operated the former Westinghouse East Pittsburgh Insulation Research Laboratory, where he gained valuable experience in understanding insulation material performance. Don holds a BS in electrical engineering from Carnegie Mellon University and is a NETA Certified Technician. Don has authored 50 technical articles for NETA World and has been featured in EC&M and Uptime magazines. Don’s work is summarized in his book, Partial Discharge & Other No-Outage Testing Methods, published in 2019.