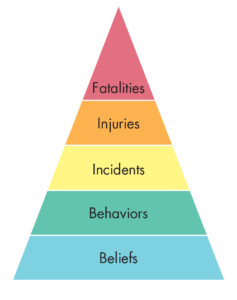

The behavioral components of incidents, injuries, and fatalities must be studied and understood to change the safety culture. This element of study has been missing from the data available to assist in improving workplace safety. Often, this type of information has never been compiled and reviewed. Figure 1 shows the relationship between incidents, injuries, and fatalities.

Figure 1: Incidents Lead to Fatalities

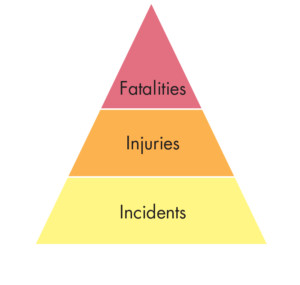

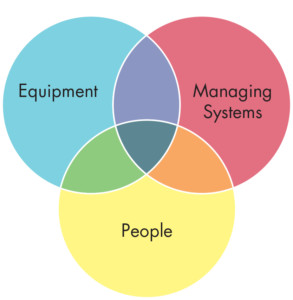

Figure 2: Elements of Human Performance

As shown in Figure 2, three primary things impact what people do: what they know, the level of their skill, and their willingness to do it. Lack of skill, experience, or knowledge has been a significant factor in every incident investigation in the past couple of decades. To improve personal safety, employees require continuing knowledge and training to perform their tasks in a safe manner. What is typically ignored is what people think and believe about the standards and procedures they are asked to follow. More time and focus on understanding why people resist accepting new requirements needs to be explored.

Every person has thoughts about the things they are asked to do. One common, unrecognized factor is that everything we see, read, and hear is filtered through our beliefs. At least one more filter applies: Experience plays a significant role in what people tend to accept. Dr. Mary Capelli-Schellpfeffer told the authors, “We can perceive only what we experience.” Everyone molds information they receive into an understanding that fits into their previous experience. In some instances, the information is completely new and cannot be molded into previous experience. When that happens, a person’s basic beliefs and principles play a role in how the person interprets the data.

Neuroscience tells us that everything we know is our own version of it. We try to make our experiences and what we see, read, and hear fit into our world, which is built around our beliefs. We seek information that aligns with what we already believe and discount or ignore information that goes against what we already believe — a process called confirmation bias. This bias is so strong that we are unable to pay adequate attention to information that goes against our beliefs even when enticed by monetary incentives or evidence that blatantly disconfirms our position. This can, and many times does, lead us to interpret standards and procedures differently from other people. Two people can watch an event and will have a different understanding of what occurred. As you read this paper, you will most likely have a different understanding of the material from what the authors intended. You will filter the material through your beliefs and experiences.

Most people arrive at work with the intention of doing a good job, doing the right things, and being a productive employee. People do what they believe is the right thing to do based on their experiences and beliefs. What needs to be explored and understood is what people believe about safety and how to influence those beliefs. It is also important to understand that different experiences and beliefs exist in every person at every level of an organization. The beliefs of management will drive behaviors that may create some of the issues that cause incident rates to remain high. For example, an emphasis on meeting deadlines can be perceived to be more important than safety.

Behaviors

What Are Behaviors?

People’s behaviors are observable. They are actions that people do or do not do. Some examples of behaviors are testing for the absence of voltage, wearing voltage-rated gloves while testing for voltage, and wearing a seatbelt while in a vehicle. If we perceive people as a collection of responses to a collection of stimuli, it fosters an understanding that behavior is predictable and thus changeable. We just have to understand how to do it.

Not taking appropriate actions is also a behavior. Not wearing your seatbelt or failing to test for the absence of voltage are also behaviors. In either context, inappropriate behaviors are unsafe acts. Observation data related to behaviors not previously recorded is a new way to find the leading indicators of possible incidents. Collecting and reviewing multiple behavioral actions is valuable to identify beliefs about safety that impede the implementation of a new or changed safe work practice. The importance of collecting and reviewing behavior-based data on an on-going basis must be stressed within organizations.

How Do Behaviors Impact Performance?

A lot of time is spent identifying unsafe acts, and not enough time is spent on why people perform unsafe acts. Unsafe acts and inappropriate behaviors are key areas that need attention because unsafe acts and inappropriate behaviors contribute to incidents and injuries. It is estimated that 91% of incidents are caused by inappropriate behaviors. Figure 3 provides another layer to the chart shown in Figure 1.

Figure 3: Behavior: A Leading Indicator for Safety

This does not mean incidents are the fault of employees. Equipment can fail and set up a situation or an unsafe condition where an employee can be injured if the condition is not recognized. An example of this is a disconnect switch where all of the blades failed to open. Failure to test for the absence of voltage has contributed to numerous incidents, injuries, and fatalities. When incidents occur, something is generally missing in the company’s safety program.

Placing blame for an incident on the employee is a behavior that managers or supervisors might exhibit. Instead, safety supervisors should focus efforts on root cause analysis with employee involvement. Fault finding or placing blame for an incident is the weakest form of changing behavior; it often teaches people to understand that they should not get caught. Fault finding or placing blame has little to do with changing beliefs or behaviors.

Because incidents, injuries, and fatalities are typically the consequences of inappropriate behaviors, we must understand which behaviors are occurring, both appropriate and inappropriate. We also need to continue to move upstream and get into leading indicators. To move upstream, we must understand why people engage in inappropriate behaviors.

What Drives Behaviors?

Preventing electrical incidents and injuries is hampered by the attitude that good workers don’t get hurt. The truth is that even the most qualified and experienced person makes mistakes in the workplace. Thankfully, most mistakes do not result in injury. What we learn from these mistakes becomes a part of our experiences. Our experiences play a large role in driving beliefs and behaviors.

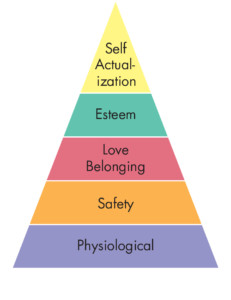

All behaviors are intrinsically driven or extrinsically driven. Intrinsically driven behaviors come from our internal beliefs. If we believe seatbelts will save our lives or prevent injury, we will use them. If we don’t believe in seatbelts, we won’t wear them. Abraham Maslow developed the Hierarchy of Needs (Figure 4), and it has been used to help understand people’s behaviors.

Figure 4: Maslow’s Hierarchy of Needs

When our needs and beliefs align, our behaviors are intrinsically driven. When our needs and beliefs are not aligned, our behaviors are extrinsically driven. It is important to understand that our needs have more impact on our behaviors than our beliefs. An example of this extrinsically driven behavior is peer pressure. Our desire to fit in can overrule even our natural, internal sense for being safe. Extrinsically driven behaviors are usually driven from needs or from people following requirements imposed upon them. They may not believe it is the right thing to do, or they may not want to do it. They engage in these behaviors because it is necessary to keep their job or get a raise. Extrinsically driven behaviors are unreliable and intermittent and may not be performed at 2:00 AM when no one is around.

Beliefs

What Are Beliefs?

Beliefs are a conviction of the truth of something derived from consideration or examination of the evidence available to us. It is a mental attitude of acceptance toward a proposition. It is an opinion. A person can and often does accept an idea as the truth based on experiences and knowledge. If the idea is work related, then experience plays a significant role in how a worker’s belief is generated.

An example of an old belief changed through experience was the belief that the world was flat. This belief was based on the existing evidence available at that time. This belief changed as new experiences proved the world was round. A more recent example is the arc flash phenomenon associated with electricity. There are still people who do not believe this is a hazard or that an arc flash will ever happen to them. They believe they do not need to take any action, such as putting on arc flash PPE. Lack of experience often leads to lack of belief in a rule or requirement related to safety. Therefore, a person’s belief may lead to a rule or requirement being ignored or not followed.

Where Do Beliefs Come From?

From the moment we are born, we have experiences. As we collect these experiences, we begin to form beliefs. We touch the hot stove and get burned. We make a connection between the hot stove and getting burned. Our belief becomes that we should not touch the hot stove because we will get burned. When we go to school, teachers provide us with knowledge and our classmates give us new experiences. We go out into the world and have experiences. Listening to the news on TV or the radio provides us with different opinions. We take all of this information and build beliefs. Each of us will have different experiences, driving us to create different beliefs.

The social culture we experience impacts our beliefs. What is acceptable in one culture may not be acceptable in another culture. Cultures exist at multiple levels. A culture can exist in a country, a state, a city, or even in the electrical shop at a facility. To some degree, we will adopt the beliefs of the culture we are in. Sometimes this acceptance is immediate; sometimes it takes time to alter our own belief system.

Our environment also impacts our beliefs. While culture and environment can be related, they are different. The culture has to do with the values of the people. The environment relates to our physical environment. For example, good housekeeping and safety go hand-in-hand. If we are assigned to a clean environment, we find ourselves behaving in a safe manner to maintain that environment. Conversely, if we find a disorganized, unclean environment, we believe a disorganized environment is acceptable. The environment may have created a belief that drives a behavior of carelessness.

These three things — experiences, social culture, and environment — all impact our beliefs. Collectively, these concepts constitute a worker’s experience. On a work site, these concepts are likely different from the person’s off-site experience. People are likely to follow safety rules at work but may ignore them in the home environment even though the hazard is the same. Ladder safety, eye protection, and hearing protection are examples. Connections about the hazards being similar or the same can be missed because there may be no job briefings, training, or discussions at home.

How Do Beliefs Impact Behaviors?

Beliefs are not visible. The relationship between beliefs and behaviors is like a tree. You see the leaves (behaviors) but not the roots (beliefs). Similarly, beliefs and behaviors are much like an iceberg: Most of the iceberg is below the surface of the water. If we do not believe a requirement or a behavior has any value, we will not perform that behavior unless we are forced or are being watched. It is unlikely we will perform the appropriate behavior if we think we can get away with not doing it. We do not believe it is necessary or has any value. It is not about being lazy or a lack of regard for the rules; it is about what we believe.

One example of a belief impacting behavior is using voltage-rated gloves. Many electricians do not think they are necessary. Common responses include: “I have been doing this for 25 years and I never needed them.” “I am not touching anything hot, so I don’t need them.” “Good electricians don’t need them.” All of these reasons are based upon belief. Experience has reinforced their belief that gloves are not necessary. Beliefs will drive a person to make a decision that will be an appropriate behavior or an inappropriate behavior (Figure 5).

Figure 5: Beliefs Drive Behaviors

If inappropriate behavior is chosen, it becomes a roll of the dice whether an incident will occur. If an incident does not occur, the inappropriate behavior is reinforced. As this cycle continues without adverse results, it can become a belief and a habit — an acquired pattern of behavior that becomes almost involuntary or automatic. Under pressure or stress, people default to their beliefs or habits regardless of procedures and training. Habits can be developed for appropriate behaviors in the same way.

Can We Change Someone’s Beliefs?

Is it possible? Yes. Is it easy? No. Changing beliefs must follow certain steps. Some beliefs are so strong people will cling to them at all costs. This must be considered when we set out to change a person’s beliefs and behaviors. John Maynard Keynes stated, “The difficulty lies, not in the new ideas, but in escaping the old ones.” We are resistant to change because it causes a change in our world and our beliefs. Telling people what to think will not change their beliefs. We have to influence how they think and what they believe. Workers must be provided with experience that challenges all previous experience. The trick is to find that new experience and provide it to the worker.

Consequences also drive beliefs and behaviors. It is important to understand which consequences control behaviors. Soon, certain, and positive consequences are the most effective in driving our behaviors.

- Timing is important. A consequence that follows soon after a behavior will control behavior more effectively than a consequence that may never occur.

- Consistency is also important. A significant consequence that is certain to follow a behavior controls behaviors more powerfully than an uncertain consequence. The significance of the consequence plays a large role in behaviors.

- A positive consequence controls behavior more powerfully than a negative consequence.

Management and peer pressure can set a positive (or negative) belief structure in an organization. A management system that accepts unsafe behaviors to get the job done can drive negative belief systems. A manager who rewards a person for getting a job done even though unsafe behaviors were taken will influence workers to believe that taking short cuts with safety is acceptable. Conversely, management that immediately addresses unsafe behaviors in the workplace will drive a positive belief system.

Peer pressure is one of the most powerful consequences in an organization because it offers soon, certain, and positive feedback that will affect beliefs and behaviors. The feeling that one is accepted by others in the workplace is a powerful factor in driving behaviors. A person’s acceptance in the work group may be more important to them than possible injuries that may or may not occur due to evading or ignoring safety requirements. Ensure that employees are involved and participate in safety. Employee involvement is key to developing positive peer pressure that will not tolerate unsafe behaviors. All safety efforts that work are effective because they influence employee behaviors.

How Do Beliefs Change?

Our brain is made up of about 100 billion cells called neurons. These neurons make connections with other neurons. All in all, the brain is capable of making 40 quadrillion connections. Our brain creates new connections with each experience doing, seeing, or hearing. These experiences become the basis for our beliefs. As experiences are repeated, the connections become layered with additional connections, making these connections strong. With repetition, the beliefs become stronger and more powerful.

Each of us builds a mental representation of our own reality, our own world, based upon our beliefs. We try to fit what we see, read, or hear into our world based on what we already believe. If the fit is not good, we may alter the concept to fit into our world. This is how we end up with different interpretations of the same concept. There are many ideas on how to change people’s beliefs.

Storytelling

Stories attract attention and are easier to remember. People relate to stories — they impact us emotionally. Important information told through a story that explains old conditions and introduces a new belief or outcome enables people to recall the information. The story must be convincing and connect to recent situations to be understood by the audience. The desired change must have a worthwhile benefit and must be seen as possible. Telling a story is one way of providing a new experience, but the story must align with the worker’s previous experience to be of value.

Autonomy, Competence, and Relatedness

This concept, discussed by Edward Deci and Daniel Pink, contains three elements: autonomy, competence, and relatedness. Each element must be addressed to change a belief. Autonomy is about being involved and having influence on the outcome. It is not about allowing a person to do whatever they please. A Stephen Covey principle — seek first to understand, then to be understood — is an example of how to understand issues and concerns when implementing a new requirement. This is a form of supportive autonomy where people engage in the process. If requirements do not gain support from the people who have to implement them, they probably were not involved in creating the requirements. By engaging people in the process, we gain buy-in from those who need to follow the requirements.

Everyone wants to be recognized as good at what they do. By encouraging people to be competent, we build understanding of the requirements. Numerous facility audits have taught us that one of our great failings is assuming people already know what is required and why. This is simply not true. We need to constantly encourage learning and provide education. People need to clearly see a purpose and a benefit in any requirement. The requirement needs to be directly connected to their job and a goal, and the goal has to be something they believe in.

Education and Training

Change is probably the only consistent thing in our world today. Codes are constantly updated. New technology is introduced. People feel left behind without training and educating. Training needs to be available in different forms. Some people learn best by reading or in a classroom environment. Some people learn best by doing hands-on work. Ongoing training is mandatory to stay on the leading edge of workplace safety.

People

For the last couple of decades, we have worked on safe work procedures and improved electrical equipment. Figure 6 shows three critical elements for addressing electrical safety. However, the third critical element of people and their underlying safety beliefs has not been an area of focus and study. People are exposed to electrical hazards and involved in the incidents, injuries, and fatalities. If their safety beliefs interfere with using the improved equipment or following the best procedures, electrical safety performance will continue to suffer. Electrical safety performance will only improve by focusing on people.

Steps to Changing beliefs

Step One: Understand people’s beliefs about safety. Observe and record behaviors showing resistant beliefs. Don’t attempt to change every behavior. Pick the most critical safety behaviors for your company or site first, then move on to others. To understand what a worker believes, become familiar with the worker’s experience. For instance, to communicate with a worker about hot work, reach a common understanding of what the term means. A worker’s understanding of the term depends on his or her previous experience.

What people believe can be seen by observing their behaviors, even if the behavior is a non-action. Observations can identify critical behaviors tied to a belief that leads to unsafe acts and are leading indicators to show underlying or hidden beliefs that will counter desired safe work practices. A shift in “Will” is vital to accepting new beliefs, creating new knowledge, building new skills, and moving behavior from extrinsic to intrinsic.

Step Two: Hold open discussions with stakeholders at all organizational levels. Open discussions are critical to understand the counter-currents to a new requirement. Openly addressing issues and beliefs in all levels of the organization, will help people align more readily with the new requirement due to involvement and a deeper understanding.

Step Three: Reinforce new beliefs and behaviors. Explain the value of the new requirements. Once beliefs have been changed, there must be continuous reinforcement of the value of new requirements. Job briefings, classroom training, hands-on training, storytelling, and use of analogies all provide reinforcement and strengthening. Similar to professional athlete training that builds strong connections and behaviors that lead to automatic habits, building and strengthening the connections in our brains through continual training and education will result in strong beliefs becoming automatic safe work habits.

Figure 6: Critical Elements of Electrical Safety

Conclusion

Changing electrical safety performance requires shifting beliefs about electrical safety and work practices. Understanding how to discover and then change people’s beliefs is the key to improving electrical safety performance. Observing, compiling data, studying the leading indicators, implementing change through inclusive methods, and sharing a unified belief about safe work practices fill in this missing element.

The next step to change electrical safety performance must address the safety beliefs of people. It takes time, but it is time well spent. Workers must be provided with new experiences they recognize as a benefit. To create an intrinsic reaction people believe is the right thing to do, their beliefs and behaviors must be willingly changed. Soon, certain, and positive consequences are the most effective in driving behaviors. Peer pressure is one of the most powerful drivers affecting behaviors in an organization. Employee involvement in safety is a key element to developing positive peer pressure that will not tolerate unsafe behaviors.

Changing beliefs comes through study, measurement, including people, and evaluating results. Providing reinforcement for intrinsic safety behaviors will create the desired outcome of improved electrical safety performance.

References

Stephen R. Covey. The 7 Habits of Highly Effective People, Fireside, New York, NY, 1990.

Howard Gardner. Changing Minds, Harvard Business School Press, Boston, MA, 2006.

Charles S, Jacob. Management Rewired, Penguin Group, New York, NY, 2009.

M. Snyder & W.B Swann Jr. “Hypothesis-Testing Processes in Social Interaction,” Journal of Personality and Social Psychology, 36, pp 1202–1212, 1978.

M. Snyder & B.H. Campbell. “Testing Hypotheses about Other People: The Role of the Hypothesis,” Personality and Social Psychology Bulletin, #6, pp 421–426, 1980.

Thomas R. Krause, John H. Hidley, and Stanley J. Hodson. The Behavior-Based Safety Process, 1990.

Dr. Mary Capelli-Schellpfeffer, et al. “Correlation between Electrical Accident Parameters and Sustained Injury,” IEEE PCIC Conference Record, Paper #IEEE-PCIC-96-3, 1996.

Edward L. Deci. Why We Do What We Do, New York, NY, Penguin Group, 1996.

A.H., Maslow. “A Theory of Human Motivation,” Psychological Review, 50(4), 1943.

Encyclopedia Britannica, Inc. Encyclopedia Britannica, 2010.

David Rock. Quiet Leadership, New York, NY, HarperCollins, 2007.

Kerry Patterson, Joseph Grenny, David Maxfield, Ron McMillan, Al Switzler. Influencer, McGraw Hill, New York, NY, 2008.

John Maxwell. Thinking for a Change, Center Street, New York, NY, 2003.

Peter Guber. Tell to Win, New York, NY, Crown Business, 2011.

Daniel Pink. Drive, New York, NY, Riverhead Books, 2009.

Danny Liggett. “Refocusing Electrical Safety,” IEEE-IAS Transactions, Sept/Oct 2006.

Daryld Ray Crow is presently the owner and Principal Technical Consultant for DRC Consulting Inc. performing work for electrical safe work practice standards, assessments/audits, electrical safe work practice training, and electrical engineering projects. He previously provided engineering support for Aluminum Company of America plants worldwide and served as team leader for developing a number of electrical standards as well as training for Alcoa’s electrical safe work practice standard. After retiring, Ray worked for Fluor Global Services and Duke Energy as a Principal Technical Specialist. Ray is a principle member on NFPA 70E Technical Committee Standard for Electrical Safety in the Workplace, is a member of the IEEE 1584 Committee, and was the working group Vice Chair for the 2007 revisions to IEEE Std. 463, Standard for Electrical Safety Practices in Electrolytic Cell Line Working Zones. He has co-authored and presented papers on electrical safety and auditing for the PCIC, the IEEE Industry Applications Society Electrical Safety Workshops, and the IEEE IAS Pulp and Paper Industry Conference. In 2010, Ray received the IEEE IAS Petroleum and Chemical Industry Committee’s Electrical Safety Excellence award. He graduated from the University of Houston in 1969 with a BSEE.

Daryld Ray Crow is presently the owner and Principal Technical Consultant for DRC Consulting Inc. performing work for electrical safe work practice standards, assessments/audits, electrical safe work practice training, and electrical engineering projects. He previously provided engineering support for Aluminum Company of America plants worldwide and served as team leader for developing a number of electrical standards as well as training for Alcoa’s electrical safe work practice standard. After retiring, Ray worked for Fluor Global Services and Duke Energy as a Principal Technical Specialist. Ray is a principle member on NFPA 70E Technical Committee Standard for Electrical Safety in the Workplace, is a member of the IEEE 1584 Committee, and was the working group Vice Chair for the 2007 revisions to IEEE Std. 463, Standard for Electrical Safety Practices in Electrolytic Cell Line Working Zones. He has co-authored and presented papers on electrical safety and auditing for the PCIC, the IEEE Industry Applications Society Electrical Safety Workshops, and the IEEE IAS Pulp and Paper Industry Conference. In 2010, Ray received the IEEE IAS Petroleum and Chemical Industry Committee’s Electrical Safety Excellence award. He graduated from the University of Houston in 1969 with a BSEE.

Danny P. Liggett has been employed by DuPont since 1989 as an Electrical Consultant with primary focus on construction activities and electrical safety. His work also involves work with maintenance activities at the DuPont sites. He is a member of the DuPont Corporate Electrical safety Team, a Senior Member of IEEE, past Chair of the IEEE IAS PCIC Safety Subcommittee, and past Chair of the PCIC Tutorials Subcommittee. He currently serves as Chair of the PCIC IAS Electrical Safety Workshop Subcommittee. Danny served as Chair of the 2000 IEEE IAS Electrical Safety Workshop and has served on the NFPA National Electrical Code Panel 8 representing the Cable Tray Institute and the NFPA National Electrical Code Panel 6 representing the American Chemistry Council. He currently represents the American Chemistry Council on the National Electrical Code Technical Correlating Committee, is an alternate on National Electrical Code Panel 3, and is an alternate on NFPA 70E. He has authored or co-authored 15 papers on electrical safety, 10 of which have been published.

Danny P. Liggett has been employed by DuPont since 1989 as an Electrical Consultant with primary focus on construction activities and electrical safety. His work also involves work with maintenance activities at the DuPont sites. He is a member of the DuPont Corporate Electrical safety Team, a Senior Member of IEEE, past Chair of the IEEE IAS PCIC Safety Subcommittee, and past Chair of the PCIC Tutorials Subcommittee. He currently serves as Chair of the PCIC IAS Electrical Safety Workshop Subcommittee. Danny served as Chair of the 2000 IEEE IAS Electrical Safety Workshop and has served on the NFPA National Electrical Code Panel 8 representing the Cable Tray Institute and the NFPA National Electrical Code Panel 6 representing the American Chemistry Council. He currently represents the American Chemistry Council on the National Electrical Code Technical Correlating Committee, is an alternate on National Electrical Code Panel 3, and is an alternate on NFPA 70E. He has authored or co-authored 15 papers on electrical safety, 10 of which have been published.

Reprinted with permission from IEEE, License Number 4762601476214