The development of standards is measured in years and often lags behind the application of the technology. In the case of distributed energy resources (DER), some unique conditions are gradually being addressed through standards and codes.

Utility-scale solar owners and their customers need to be able to evaluate the reliability of the system at commissioning and throughout the life cycle to ensure power delivery on demand. The focus of this article is the testing associated with in-place cables, connectors, and splices for AC and DC cables in utility-scale solar applications and USA-based standards organizations.

American Clean Power (ACP) is the primary trade association for alternative energy in the USA. The technical portion of its mission includes the development of consensus ANSI standards and technical guidance from cradle to grave. ACP’s Balance of Plant Group has developed three documents:

- Wind and Solar Underground AC Collection System Cable Testing (September 2023)

- Splice Body and Termination Playbook (presently under revision)

- Operations and Maintenance Recommended Practices, Second Edition (2017)

Since 2020, many standards and testing methodologies related to solar cables have been updated within IEEE standards, including IEEE Std. C-2023, National Electric Safety Code (NESC), as well as NFPA 70, National Electrical Code (NEC) including Article 691 Large-Scale Photovoltaic (PV) Electric Power. Questions still remain, including the allowable number and location of splices on a large-scale solar project.

The common cable insulation system in ACP’s Wind and Solar Underground AC Collection System Cable Testing is a TR-XPLE with concentric neutrals and a polyethylene outer jacket. The document notes that the collection voltages tend to be 34.5 kV but can be an average of 69 kV depending on local codes. Due to the miles of cables and locations associated with utility-scale projects, water-tree retardant materials, high temperature resistance, and shielded cable must be used for the higher voltage cable. Any exposed cable is generally PV-rated, which indicates it is resistant to ultraviolet (UV) and weather conditions.

DC cables are generally rated and tested to UL Std. 4703, Photovoltaic Wire, and are now allowed to be rated up to about 2,000 volts, higher thermal classifications, and wet or dry applications. These conductors run from the panels to terminal boxes and the inverter. Cables from the inverter to the step-up transformer, which generally have two primaries starting at 390 Vac with a secondary of either 34.5 kV or 69 kV, are generally rated to the same value as the PV cable. The cables after the step-up transformer are referred to as collector cables.

Concerns ranging from workmanship to transients such as natural and incorrect operating conditions can generate reliability issues.

- Workmanship includes problems with incorrect treatment of insulation, direct burial issues, alignment, and splicing.

- Transients include weather, such as lightning, and operating conditions such as capacitor bank operation, and some suggest excessive testing.

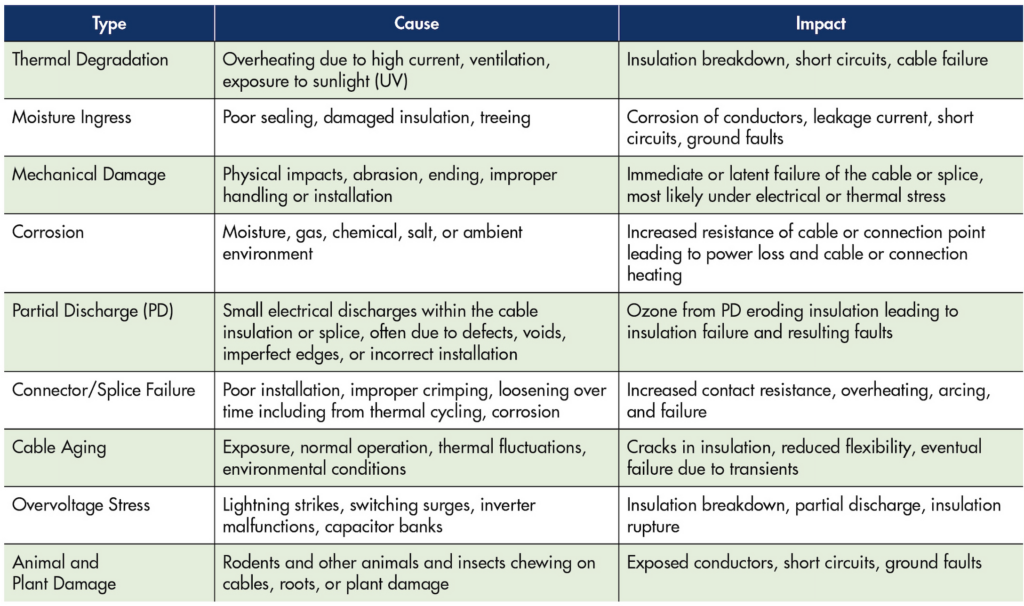

Splices are generally applied to extend the cabling length or to repair damaged sections of cable. As large solar projects continue to expand, the number of splices can be in the hundreds. Many of the splices have been rated for utility use, but are not necessarily rated for renewable energy. Over the last decade, the number of unexpected failures due to cable, splices, and connectors has increased dramatically and presently represents a reported 83% of the outages, according to The Solar Grade PV Health Report. The common causes of failure in cables, connectors, and splices on solar sites are noted in Table 1.

STANDARDS AND TESTING

For most failure types, visual inspections, withstand tests, and diagnostic tests can provide insight into condition.

- Visual inspections, normally the best option for detecting most defects, cannot be used for buried or hidden defects. Another challenge, depending on the site, is that the splice locations may not be recorded, especially if buried.

- Withstand testing, as outlined in IEEE Std. 400, IEEE Guide for Field Testing and Evaluation of the Insulation of Shielded Power Cable Systems Rated 5 kV and Above includes high potential (HiPot) and VLF testing.

- Diagnostic and monitoring tests include dissipation factor/tan delta, leakage current, recovery voltage, polarization/depolarization, dielectric spectroscopy, on-line and off-line partial discharge, acoustic partial discharge, time domain reflectometry, and thermal infrared imaging. It is noted that Wind and Solar Underground AC Collection System Cable Testing outlines specific owner and OEM consensus tests, including IEEE and ACP recommended values with suggested pass/fail values. It is important to verify that the tests are related to the applied voltage. Note that a few types of defects, especially those related to workmanship, can only be detected in later stages of degradation.

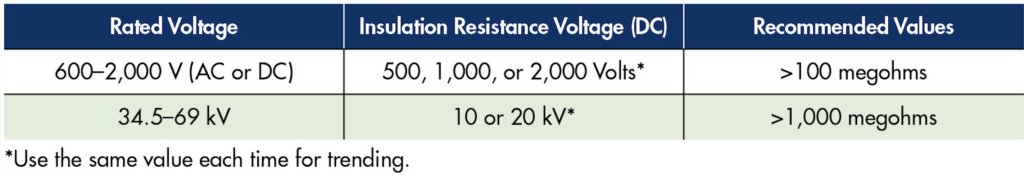

Simple DC resistance and insulation to ground resistance are performed with a megohmmeter set for 500 V to 20 kV DC applied from conductor to ground for 1 minute. ACP’s Operations and Maintenance Recommended Practices recommends the values in Table 2 for applied insulation resistance voltage and recommended values. Editor’s Note: These values for insulation-resistance applied voltages and the recommended acceptable criteria differ from NETA specifications.

It is important to note that a low value indicates that further inspection is required. Unlike electric machinery, polarization index and dielectric absorption are less useful on cables. If trending or referencing values, the insulation resistance test should be performed at similar temperatures and humidity, as these can dramatically alter the results.

DC High Potential Test

Preferred to AC high potential testing, DC high potential testers normally provide leakage currents at the applied voltage. When using the applied values for the DC high potential test on cables specified in IEEE Std 400.1-2018, IEEE Guide for Field Testing of Laminated Dielectric, Shielded AC Power Cable Systems Rated 5 kV to 500 kV Using High Voltage Direct Current (HVDC), DC high potential testing must be performed when the cable has cooled to ambient temperature and start at no more than 1.8 times the phase to phase voltage of the cable. The steps must be increased in five 1-minute increments to the calculated values and then held at the maximum voltage for 15 minutes. Editor’s Note: These specifications differ from those in ANSI/NETA ATS, Table 100.6.1.

The cable insulation must be discharged before re-energizing to avoid damage to the cable. The discharge must go through the instrument or through a calculated resistance and not be directly shorted to ground. The leakage values should increase linearly.

Failed tests are indicated by:

- A sharp change or gradual increase in current at a fixed voltage value

- A trip of the test system, which may indicate a flashover from the tester

- Failure of the cable, a splice, or a connector

If a failure occurs during high potential testing, the source of failure must be determined before energizing the cable.

VLF High Potential Withstand Test

A very low frequency (VLF) high potential test combines AC high potential and DC high potential tests. It provides the benefits of both types of tests and is generally applied as identified in IEEE Std. 400.2-2013, IEEE Guide for Field Testing of Shielded Power Cable Systems Using Very Low Frequency (VLF)(less than 1 Hz). The preferred sinusoidal VLF applies 3 times the voltage to ground rating of the cable at 0.1 Hz to 1 Hz for 15, 30, or 60 minutes. The test passes if the insulation system does not rupture or fail. In some cases, the VLF test will fail defects and leave the good portion of the electrical insulation system intact. It is important to note that the ACP recommends the 0.1 Hz value.

Off-Line Dissipation Factor/Tangent Delta Test

Dissipation factor/tangent delta tests are normally performed as part of a VLF test set as outlined in IEEE 400.2. The dissipation factor compares the cable insulation system capacitance against a perfect capacitor value, resulting in a value that can be trended. In general, test values of 0.01% to 0.5% are considered acceptable for a new insulation system. For older, but good cables, the values will generally fall within 1–2%, while cables with values higher than 2% should be considered significantly degraded. However, the results will not identify specific defects.

Off-Line Partial Discharge Test

While off-line PD has been used as part of commissioning tests for solar collection cabling, it has also proven to be excellent for testing aged cables. The method follows IEEE Std. 400.3-2022, IEEE Guide for Partial Discharge Field Diagnostic Testing of Shielded Power Cable Systems and generally will detect most defects in cable insulation systems considered medium voltage. The test provides a trend-able set of values and can also be used to accurately locate defects. In off-line PD, a line-frequency AC high potential tester is set up to briefly produce up to twice the operating voltage to detect voids or cavities within the insulation system or at interfaces between the insulation and semiconducting shields, including some manufacturing defects or physical damage as well as interfacial cavities in accessory interfaces and splices, a high-resistance insulation shield or damaged neutral, and electrical treeing. ACP identifies that no defect should surpass >5 pC (pico-coulombs).

ACP’s Wind and Solar Underground AC Collection System Cable Testing identifies that the VLF tester can be used at 0.1 Hz to perform a less effective PD test.

On-Line Partial Discharge Test

On-line PD testing is performed when the equipment is de-energized and uses a capacitive coupler or high-frequency transformer to detect PD. On-line PD is generally used to identify that a defect exists but not the exact location of the component. However, the system is generally considered excellent for continuous monitoring, and the values are trend-able. PD testing is a comparative value that is trended over time and is generally used to trigger additional testing.

Acoustic Partial Discharge Test

Although not included in any of the ACP documents, acoustic PD testing is performed at values up to about 105 kHz and requires a sound path. It is normally performed on exposed equipment and relies on the sound pressure of corona or partial discharge to detect.

Infrared Imaging

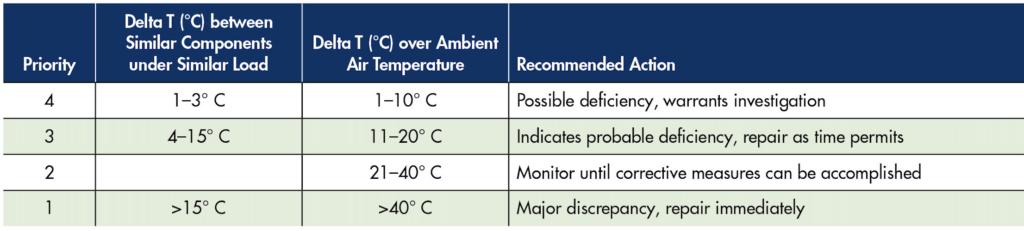

Infrared imaging is used to evaluate hot spots that result from loose or damaged connections. This provides a line-of-sight testing method to detect loose or corroded conductors as well as damaged splices and connectors. Values should generally be less than 5° C above ambient or similar conductors. While considered important, recent standards leave out the pass/fail values that are recommended. In this case, we will rely upon the values recommended in the Infraspection Institute’s Standard for Infrared Inspection of Electrical Systems and Rotating Equipment (Table 3).

DISCUSSION

Lower-voltage cables such as DC cables and inverter to transformer cables generally use visual, insulation resistance, and infrared and may include high potential testing. VLF, PD, and related tests are generally performed on cables over 5 kV. Some specialty test devices have been developed for lower-voltage DC systems.

The higher-voltage collector cables that make up a majority of the systems should be inspected with VLF, dissipation factor/tan delta, and some form of partial discharge tests. There is no set frequency for these tests but Wind Operations and Maintenance Recommended Practices, Section 601 Annual Testing offers recommendations.

The Wind O&M document also highly recommends that cable fault location equipment, or thumpers, are not used as they subject the long lengths of cables to unnecessary surges that reduce their remaining life. When applied, they should be limited to fault location and use reduced voltages. Editors Note: NETA prefers the use of time domain reflectometry (TDR) for locating cable faults as it is a highly effective, non-destructive method for identifying fault locations in cables. This practice is not identified in ACP standards or best practices.

The tests in this article are not considered an exhaustive list or outline for solar applications and the ACP Balance of Plant group may expand the list and pass/fail results from site and OEM experiences. Nothing is preventing additional testing at a solar site, but the testing and the pass/fail criteria must be understood by stakeholders before proceeding.

CONCLUSION

Cables, connectors, and splices make up a majority of faults on a solar farm. As a result, the use of prognostic technologies for evaluating the components is recommended. American Clean Power has used consensus practices to determine the best methods and test values to be used for evaluating the DC and collector cable systems for reliability and, in part, to help locate the issues.

In addition to visual and withstand tests — generally pass/fail evaluations — recommended condition-based maintenance tests that trend and locate potential faults are available. These should be performed annually or adjusted based on the operating environment. Any defects should be recorded, and a root cause should be determined.

REFERENCES

Solar Grade. The Solar Grade PV Health Report, Second Edition, 2024. Accessed at https://solargrade.io/articles/the-solargrade-pv-health-report/.

American Clean Power. Wind and Solar Underground AC Collection System Cable Testing, September 2023. Accessed at https://cleanpower.org/wpcontent/uploads/gateway/2023/09/Wind-and-Solar-Underground-AC-Collection-System-Testing_ACP.pdf.

American Clean Power. Splice Body and Termination Playbook, (presently under revision). Accessed at https://cleanpower.org/wp-content/uploads/gateway/2024/08/Splice-Body-and-Termination-Playbook_240712-1.pdf.

American Clean Power, AWEA O&M Committee. AWEA Operations and Maintenance Recommended Practices, Second Edition, 2017. Accessed at https://cleanpower.org/resources/awea-operations-maintenance-recommended-practices-second-edition/.

UL Std 4703, Photovoltaic Wire, August 11, 2020. Accessed at https://www.shopulstandards.com/ProductDetail.aspx?productId=UL4703_1_S_20140930

IEEE Std 400.1-2018, IEEE Guide for Field Testing of Laminated Dielectric, Shielded AC Power Cable Systems Rated 5 kV to 500 kV Using High Voltage Direct Current (HVDC). Accessed at https://ieeexplore.ieee.org/document/8633029.

IEEE Std. 400.2-2013, IEEE Guide for Field Testing of Shielded Power Cable Systems Using Very Low Frequency (VLF)(less than 1 Hz). Accessed athttps://ieeexplore.ieee.org/document/6517854.

IEEE Std. 400.3-2022, IEEE Guide for Partial Discharge Field Diagnostic Testing of Shielded Power Cable Systems. Accessed at https://ieeexplore.ieee.org/document/10123370.

Infraspection Institute-2016, Standard for Infrared Inspection of Electrical Systems & Rotating Equipment. Accessed at https://infraspection.com/infrared-standards/.

Editors Note: NETA’s approach has always been to first recognize the project specs, followed by OEM requirements, and then NETA specifications. This article explains other specifications that are based on the authors unique experience and perspective.

Howard W. Penrose, PhD, CMRP, CEM® CMVP is President of MotorDoc® LLC, a veteran-owned small business. He was a U.S. Navy electric machine repair/rewind journeyman (NEC 4619/4621) and is the 2022-2025 Chair of Standards Development at American Clean Power. Penrose is the past chair of the Society for Maintenance & Reliability Professionals (SMRP) and currently serves on the SMRP Government Affairs Team for workforce, smart grid, cybersecurity, and infrastructure, among numerous other energy/environment/ workforce programs. He is the past chair of Chicago Section IEEE; an active member of IEEE standards committee(s); a past Senior Research Engineer at the University of Chicago Energy Resources Center; chair of the committee for wind/solar/energy storage standards for the USA through American Clean Power (formerly AWEA); and the U.S. appointee to CIGRE Working Group A1 Electrical Machines for those topics. He is a five-time recipient of the UAW-GM People Make Quality Happen Award and is a leading researcher of ESA/MCSA applications. Penrose received his PhD in industrial-general engineering and is certified in data science and machine learning from Kennedy Western University, Stanford University, the University of Michigan, IBM, and AWS. He is also a Certified

Maintenance and Reliability Professional through the Society for Maintenance and Reliability Professionals, and a Certified Energy Manager and Certified Measurement and Verification Professional through the Association of Energy Engineers.