When a generator owner plans site upgrades that result in protection setting or coordination changes, compliance with several North American Electric Reliability Corporation (NERC) Reliability Standards such as PRC-019, PRC-024, PRC-025, PRC-026, PRC-027, MOD-025, and MOD-026 will be impacted, depending on the scope of the upgrade. However, the effort to maintain compliance — and equally important, maintain compliance documentation — is often overlooked during initial planning for the project timeline and budget.

These efforts are often incorrectly considered insignificant in the grand scheme of the upgrade project. Regardless of the reason, not considering compliance impacts will at best result in inefficiencies, unwanted delays, and unanticipated expenses. At worst, it will leave the post-upgrade site non-compliant. Being aware of the compliance impacts of site upgrades and considering them during the initial scoping process will result in a more likely compliant post-upgrade site, more realistic timelines and budgets, and ultimately lower long-term effort.

COMPLIANCE IMPACTS

The reliability of the North American grid is of utmost importance. Without reliable operation, disastrous events such as those demonstrated in the historic August 14, 2003, blackout in the eastern United States and Canada can occur. After this event, the U.S.-Canada Power System Outage Task Force recommended that NERC and other regulatory organizations require compliance with reliability rules.

While there are many reliability rules, this article focuses on several of NERC’s Protection and Control (PRC) and Modeling, Data, and Analysis (MOD) Reliability Standards. NERC PRC standards are concerned with setting protection and control settings so they will not unnecessarily trip units when the grid requires support and it is still reasonable for a site to operate. NERC MOD standards are concerned with accurate model information being used in studies. NERC Reliability Standards discussed here include:

- PRC-019: Requires coordination of generation limiters, protection, and equipment capabilities

- PRC-024: Requires frequency and voltage protection to be set at acceptable levels when considering voltage drop from the protection location to the high side of the generator step-up (GSU) transformer

- PRC-025: Requires load-responsive relays to not limit the output of the generation

- PRC-026: Requires generator relays to not trip during stable power swings

- PRC-027: Requires coordination of protection responses during faults

- MOD-025: Requires verification of reported generation reactive power capability

- MOD-026: Requires verification of modeled generator excitation control system and plant volt/var control systems

These standards are designed to focus on different aspects of reliability. Together, and with other standards, they aim to ensure the overall reliable operation of the grid. If these standards apply to a site, then being compliant is important not only because it is required but also because it promotes a stable and usable grid. Depending on the scope of site changes being made, compliance with these NERC Reliability Standards may be impacted.

Protective Equipment Upgrades

Common protective equipment upgrades include replacing the automatic voltage regulator (AVR) or protective relays. If the new AVR or relays include tripping protection, the relevant settings may need to be assessed against PRC-019, PRC-024, PRC-025, PRC-026, and PRC-027. Relevant AVR limiters must also be assessed against PRC-019.

Since a new AVR results in a new volt/var response from the unit, an AVR replacement also triggers MOD-026 reassessment to develop and verify an updated positive sequence exciter model. MOD-025 and verification of the unit’s reactive capability limits also must be considered.

Compliance concerns are triggered by protective equipment replacements, but changing relevant settings within existing protective equipment can also affect compliance with NERC Reliability Standards. For example, if a site wishes to take advantage of additional elements in an existing multifunction relay, relevant PRC assessments such as PRC-019, PRC-024, PRC-025, PRC-026, and PRC-027 must be updated to reflect the newly enabled protective element in the relay. This is also true if relevant protection settings are changed or newly enabled in an inverter-based resource.

If protection or limiter settings are changed in an existing AVR, relevant PRC assessments must be updated as well. Changing limiters may also prompt MOD-025 verification if the reactive capability of the unit is changed by more than 10%. If the volt/var response of the unit is changed, then MOD-026 reassessment is also needed.

Non-Protective Equipment Upgrades

Compliance concerns can also be triggered by making changes to non-protective equipment if equipment capabilities have changed or if upgrading the equipment requires changes to the existing protection settings to establish proper coordination.

For example, if the generator is rewound or the generator step-up (GSU) transformer is replaced, the V/Hz capability of the generator or GSU may change. The new V/Hz capability curve for the equipment must be obtained from the manufacturer, and the PRC-019 documentation must be updated to include an assessment of the existing protection against the new capability curve.

If the generator rewind or the GSU replacement results in different capabilities and the existing protection no longer properly protects the equipment, the AVR and/or the relay V/Hz protection may also need to be updated. PRC-019 documentation then needs to include the updated V/Hz capability curve assessed against the updated V/Hz protection settings. Changing any tripping V/Hz protection settings would require the PRC-024 assessment to be updated as well. In some cases, the site may need to follow the PRC-027 R1 process to make these changes, even though these are not load-responsive elements.

While not related to protective setting upgrades, if a generator is rewound, the unit must be reassessed against MOD-026, according to NERC guidance, to verify the upgraded unit response against the generator’s positive sequence model response. If the rewind prompted relevant changes in the existing AVR settings, the existing exciter model may require updates as well.

Site Upgrade Examples

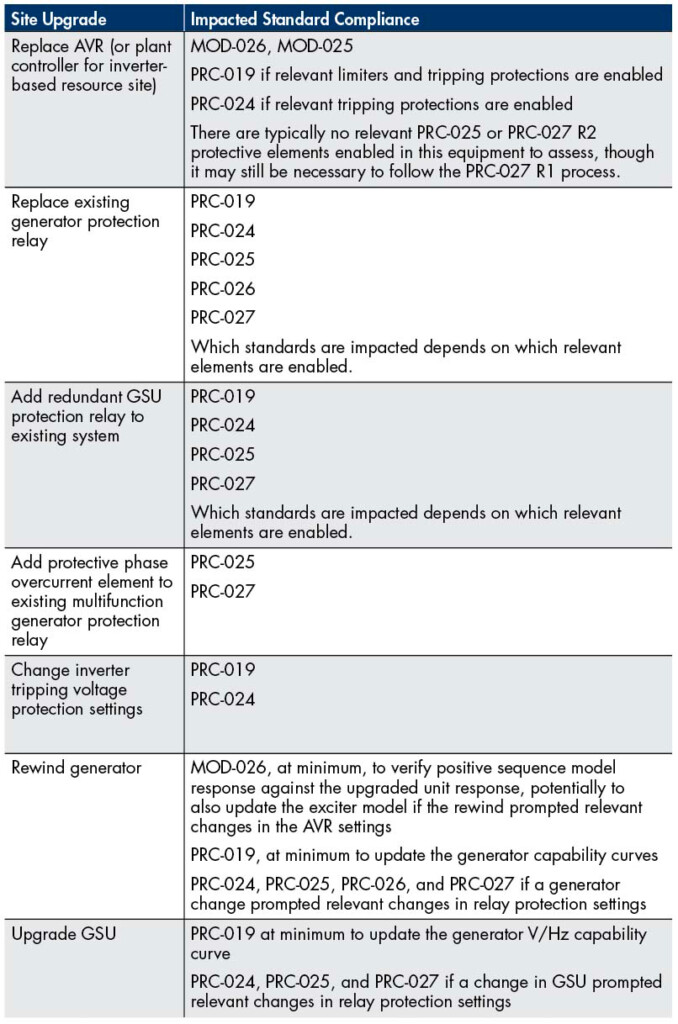

Table 1 includes examples of site upgrades, impacted standards, and comments regarding possible impacts. This is not a comprehensive list of applicable upgrades or impacted standards. Each site has unique aspects that may change how standards apply and why, which should be carefully considered.

Note that while the table is consistent with current versions of the referenced NERC Reliability Standards, many are currently being revised to change how inverter-based resources are considered. New revisions of the standards may change how site upgrades and setting changes impact compliance.

BENEFITS OF PLANNING AHEAD

One clear advantage of planning ahead and considering compliance during the initial scoping of a site change is the increased likelihood of being compliant when the site changes are complete. However, there are additional benefits.

Reduced Effort

By including compliance documentation efforts in the initial scope, a site can double-dip on effort. If it is known from the beginning which documentation is needed, the same effort can go towards determining protection settings or coordination changes and towards developing the necessary compliance documentation. For example, protection settings can be initially developed considering the requirements of applicable NERC PRC standards so that when it comes time to create the PRC compliance documentation, the necessary plots, calculations, etc., are already available and were developed with the final presentation in mind. While any protection setting or coordination changes should be made according to relevant PRC requirements, starting with the final compliance documentation in mind reduces duplicated effort and therefore reduces the cost for the project as a whole.

Considering all relevant compliance concerns before starting protection setting or coordination changes also means the effort can take a more holistic approach. For example, new settings can be developed from the start knowing the boundaries of the relevant PRC requirements as opposed to an iterative process of developing initial settings that coordinate with equipment capabilities, checking the settings against one relevant standard, adjusting the settings to meet the requirements of the standard, checking compliance against another relevant standard, adjusting the settings again, checking the new settings against the first standard again, and so on.

Setting and Coordination

Using a holistic approach from the start can reduce these iterations and the necessary effort, but it can also lead to better overall setting or coordination changes across the upgrade. The NERC Reliability Standard requirements provide guidance on reliability concerns that should be considered when making protection setting or coordination changes. Looking at the changes from the multiple angles of the applicable standards at the same time allows a site to actively balance these reliability concerns to create their desired protection scheme.

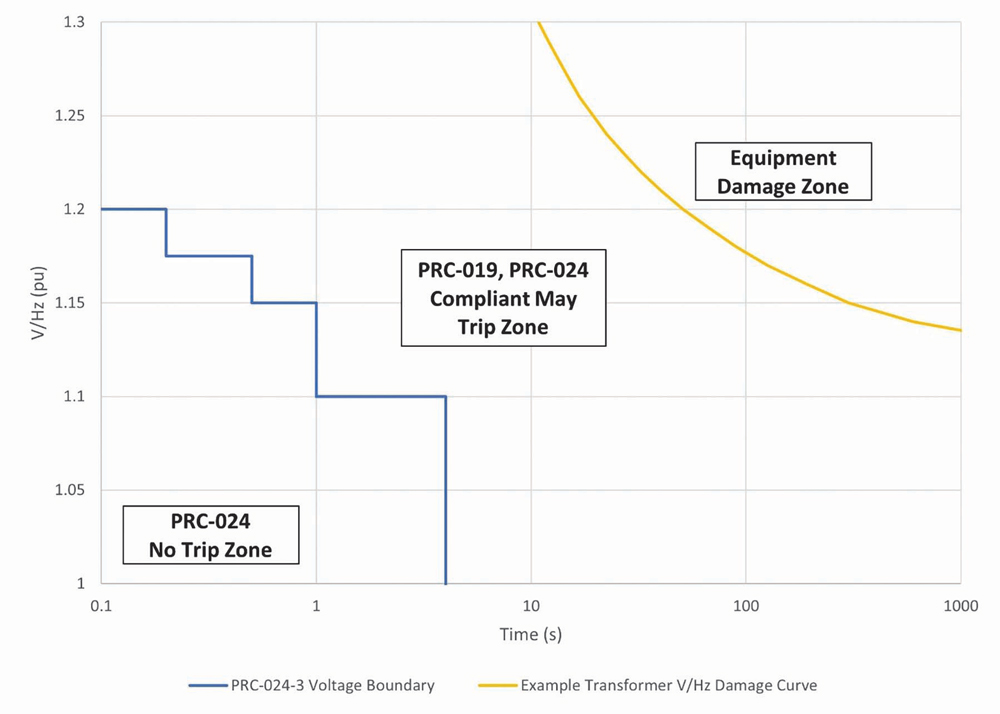

Note that while compliance with NERC Reliability Standards is an important consideration when making protection setting or coordination changes, it is not the only consideration. Generally, NERC compliance can provide a lower boundary for protective settings while equipment capabilities provide an upper boundary, as shown in the V/Hz example in Figure 1. Other factors, such as non-NERC-applicable equipment capability limits, site-specific protection risk tolerance, and the overall site protection scheme should also be considered.

Budget Accuracy

Considering compliance efforts during the initial scoping and planning stage means the project-specific budget will more accurately reflect the actual cost associated with the site update effort. Having a more accurate cost ensures that the necessary money can be requested in yearly budgets to sufficiently cover all compliance efforts and not leave any loose ends that can have larger financial impacts later.

Transmission Planner Communication

PRC-027-related protective setting or coordination changes require communication with the site’s transmission planner (TP) to establish agreed-upon coordination between electrically connected entities per PRC-027 Requirement R1. It can take time to establish communications with the correct TP contact, in addition to the time it takes to resolve any coordination concerns. Conversations should be started early to give the TP notice of the intended changes, even if the final protective setting or coordination changes are not available yet. This is also an opportunity to request any coordination requirements from the TP that can be used to develop the protective setting or coordination changes and reduce the iterations in the conversation, further streamlining the process.

OTHER CONSIDERATIONS

Several additional considerations can further help streamline the overall effort for a site upgrade and set a site up well for the future, especially when paired with considering compliance efforts during initial planning.

Assessment Addendums Versus New Reports

When performing a site upgrade such as a relay replacement that duplicates the existing protection, it may be tempting to create an addendum to attach to the existing PRC compliance documentation. Creating an addendum that documents the existing settings, the updated settings, and the consistency between them — and therefore assuming that the coordination of the updated settings is the same as the existing settings — may seem like a smaller amount of effort in the short-term at first glance, but it raises significant long-term concerns.

Adding addendums to existing documentation creates an additional piece of documentation to keep track of, which requires additional effort to maintain. It also creates a longer paper trail to prove compliance. In the event of an audit, this leaves an auditor with additional dots to connect, additional questions for a site to answer, and more spots for potential holes to be found.

New NERC PRC compliance documentation should be developed to cleanly and clearly document how the upgraded settings coordinate directly against and meet the requirements of the relevant NERC PRC standards to supersede the previous documentation. Not only does this reduce the effort to maintain the latest documentation, but it also reduces the effort required by a potential auditor to connect the dots between the protection and compliance with the requirements, thereby reducing the potential effort (and stress) for a site during an audit.

Manufacturer Information

Upgrading non-protective equipment such as a generator or GSU is a good opportunity to get all the appropriate information from the manufacturer. Knowing the relevant compliance concerns before beginning the project will guide which information to request. Information such as the manufacturer V/Hz capability curves, manufacturer V/Hz protection recommendations for the equipment, or rotor current withstand curves can be difficult to get for existing units but are the best representation of a unit’s capability. Manufacturer information is more specific to the equipment than typical curves or IEEE standards, even if it is consistent with these sources. This also makes them ideal for demonstrating NERC PRC compliance.

If an AVR is being upgraded, documentation from the manufacturer that describes the details of the limiter settings and operation for PRC-019 compliance should also be requested. Using clear manufacturer information to the extent possible results in a cleaner, more auditable compliance document and further reduces any holes that an auditor may identify.

CONCLUSION

Site upgrades are full of complex factors that can result in last-minute stressors and expenses, but compliance with NERC Reliability Standards doesn’t have to be one of them. Compliance and the associated costs are a necessary part of a site upgrade project to meet mandatory requirements, but also to ensure the grid operates reliably as needed and expected by everyone who uses it. Planning ahead and handling compliance upfront is the best strategy for meeting these critical reliability concerns and doing so in a streamlined and cost-effective way.

Casey Whitt, PE, graduated from Oregon State University with a BS in electrical and computer engineering and a minor in computer science. She started her career at Ready Technologies, which is now part of Shermco Industries, where she is currently the Lead Engineer for the Power System Stability Group. Her current areas of focus are positive sequence modeling, electromagnetic transient modeling, and protection system design, particularly related to assessing NERC, CAISO, and ERCOT compliance. She is registered as a Professional Engineer in the state of Washington.