As energy storage systems (ESS) become more integrated into our society, the National Fire Protection Association (NFPA) provides resources to ensure they are installed safely and that our firefighters are prepared to respond to the safety issues they present. Even though batteries have been around for hundreds of years, new innovations allow us to do more with them than ever before. There is a need for more information about the hazards associated with these technologies, as well as methods to reduce the risks associated with them. NFPA aims to help solve this problem by providing resources in the form of codes, standards, training, and research reports.

An energy storage system, in basic terms, is something that can store energy for use as electrical energy at a later time. An example of this is a battery, and an ESS that utilizes batteries is called a battery energy storage system (BESS). One of the most used battery technologies today is lithium-ion. Although there are many different types of lithium-ion batteries, such as lithium iron phosphate and lithium cobalt oxide, we often refer to them as lithium-ion batteries since they share a lot of commonalities. This article focuses on lithium-ion BESS.

Applications

Many applications help drive the development and production of newer and larger BESS installations.

- A BESS can be used for a practice called peak shaving, where batteries are charged when electrical demand on the grid is low and then discharged when electricity is in high demand. Since electrical prices can fluctuate throughout the day, this gives users the opportunity to buy electricity at a lower price and use that cheap electricity when the price of electricity is high.

- A BESS can supplement renewable energies such as photovoltaic panels (solar panels) or wind turbines. A BESS makes it possible to use electricity generated from these renewable resources when the sun and wind are not present.

- A BESS helps support our electrical infrastructure. When power generation facilities ramp up and ramp down to keep up with the changing demand for electricity, it puts stress on the system. BESS can help flatten out the demand curve by charging when electrical demand is low and discharging when it is high.

- A BESS can be used as a secondary source of power, similar to generators for a building.

With all of these applications and the potential for financial benefits, you can see why BESS use is increasingly common.

Hazards

Along with all of these benefits, battery energy storage systems come with some drawbacks due to hazards. Like with all electrical equipment, shock and fire hazard is present. A BESS also has the unique attribute of being able to go into thermal runaway. This is when one cell of the battery rapidly and uncontrollably overheats, often spreading to adjacent cells and usually leading to a high-intensity fire that is very difficult to extinguish.

A BESS also generates toxic and flammable gasses when it goes into thermal runaway. Once a BESS fire is extinguished, there is the risk of stranded energy, where electrical energy is trapped in the unit and is unable to be discharged safely or easily. This is potentially dangerous for those who are combating or cleaning up after the fire, since shock hazard is present. This stranded energy can also lead to spontaneous reignition. A BESS fire is truly a challenge to extinguish.

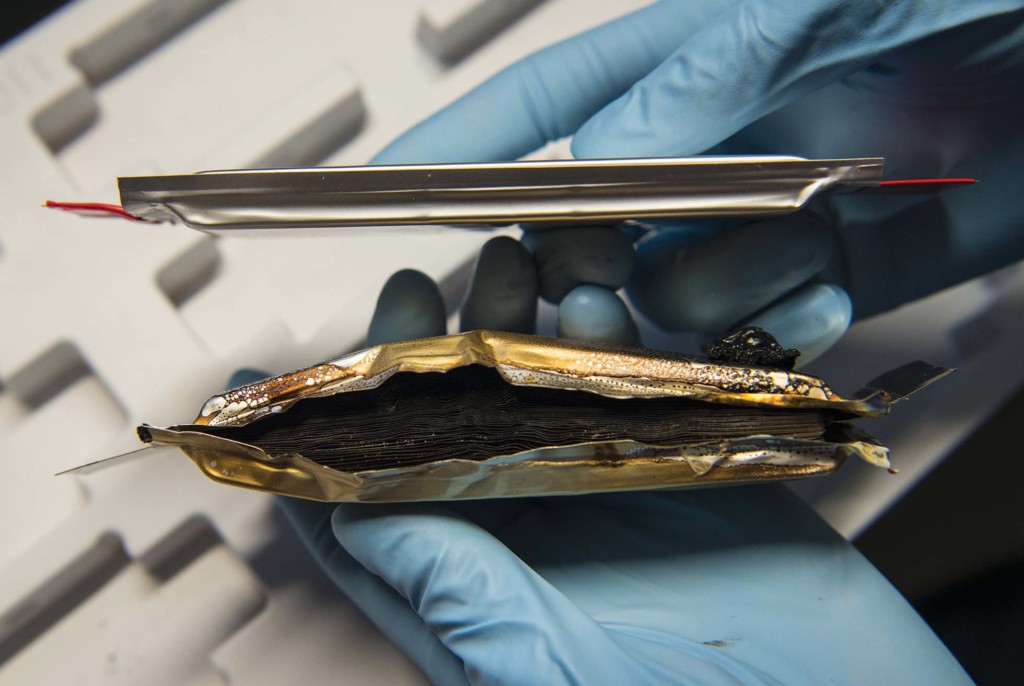

October 18, 2018 – NREL researcher Nate Sunderlin holds a lithium ion battery that has failed after being punctured, next to an intact battery, in an experiment in the Science of Safety Facility in the Materials Characterization Lab at the ESIF. (Photo by Dennis Schroeder / NREL)

Failure Modes

The batteries in a BESS can fail in several ways, often leading to thermal runaway. Batteries can undergo electrical abuse by being charged or discharged too rapidly or charged at voltage that is too high. Internal faults such as poor design or deficiencies in manufacturing can lead to failure. Another path to failure is environmental impact from seismic activity, animal damage, floods, or extreme heat. Mechanical abuse, such as dropping, crushing, or penetrating the battery can also cause a battery to fail.

NFPA 855

NFPA, in partnership with the Fire Protection Research Foundation (FPRF), has been hard at work the past few years developing resources for those who need it. NFPA is a global advocate for the elimination of death, injury, property, and economic loss due to fire, electrical, and related hazards. To address many of the issues and concerns over BESS, NFPA developed NFPA 855, Standard for the Installation of Stationary Energy Storage Systems. This standard provides requirements for users to be able to design and install ESS. NFPA 855 only applies to installations of a certain size, meaning that this standard isn’t intended to apply to smaller consumer electronics.

Emergency Operations

The standard’s requirements address the need for an emergency operation plan containing elements such as procedures to safely shut down the system, procedures for the removal of a damaged BESS, general emergency procedures, and annual staff training. These requirements are designed to increase preparedness so staff and responders know exactly what they should do in the event of an incident. This is an essential part of emergency management and can help mitigate losses if done correctly.

Equipment

NFPA 855 also contains requirements for all of the components that make up a BESS. In short, all of the individual components must be listed to a specific standard and the system as a whole must be listed. This ensures that the BESS is comprised of safe components that will minimize the chance of an incident occurring.

Location

The impacts of the hazards presented by a BESS can differ based on the location where they are installed. For that reason, NFPA 855 contains different requirements for systems that are installed in various types of locations, which are broken down into two categories: indoors and outdoors. The subcategories of indoor use include dedicated-use buildings, non-dedicated-use buildings, and sleeping/dwelling units. Outdoor locations are subcategorized into remote locations, which are installations that have no exposures 100 feet in any direction, non-remote locations, and rooftop/open parking garages.

Compliance

It is important to comply with all of NFPA 855’s requirements; these are the most impactful when designing and installing a system.

• NFPA 855 requires a BESS to be grouped into 50kWh groupings spaced 3 feet from other groups and walls. The purpose of this requirement is to prevent horizontal fire propagation, which can lead to long-duration fires that can overwhelm the water supply. It is worth noting that remote outdoor locations are exempt from this requirement.

• There is a limit on the number of BESS you can install in a fire area before it is considered a high-hazard occupancy. For lithium-ion batteries, this maximum stored energy limit is 600kWh. This requirement is intended to limit the size of a fire in any one area.

• Since early detection and response is key to limiting fire size, smoke and fire detection must be installed in accordance with NFPA 72. A sprinkler system must also be installed in accordance with NFPA 13, Standard for the Installation of Sprinkler Systems. Several NFPA requirements, such as the requirement for spacing and a sprinkler system, can be altered based on the results of large-scale fire testing done in accordance with specific testing procedures. This is permitted because there is still much we do not know about BESS fires, and the committee of experts who wrote the standard wanted to encourage testing since there is not much publicly available testing data. If users can prove through testing that a different suppression system or a closer spacing can be safe for their installation, NFPA 855 permits those variations from the prescriptive requirements.

Adoption

Now that we are familiar with some of NFPA 855’s requirements, a common question is “how does adoption and enforcement work?” States and jurisdictions are always free to adopt whatever codes or standards they want, but the main path of adoption for many smaller standards is to have them referenced in NFPA 1, Fire Code. Since NFPA 855 was published at the end of 2019, the plan for the next edition of NFPA 1, which is due to be published by the end of 2020, is to both extract and reference NFPA 855. This is when you can expect to see broader adoption of the NFPA 855 standard, although many jurisdictions have already adopted and are enforcing it.

FPRF Reports

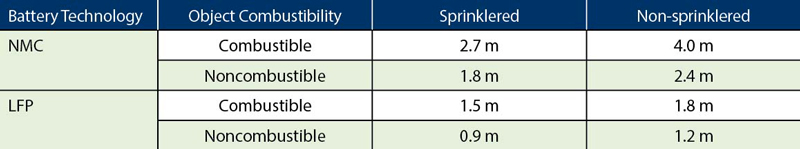

The FPRF is an NFPA research affiliate whose mission is to plan, manage, and communicate research in support of the association. In the past few years, the FPRF has carried out many research projects related to BESS, all of which are free for download from the NFPA website. One recent FPRF research report, Sprinkler Protection Guidance for Lithium-Ion Based Energy Storage Systems published in 2019, demonstrated large-scale fire testing of BESS units. This research builds upon previous studies that indicate water is the most effective suppressant for combating lithium-ion battery fires. While the study acknowledges the large number of unknowns when it comes to these incidents due to the lack of publicly available data, it attempts to shed light on how these battery systems behave in fire conditions and what effect a sprinkler system can have. Two types of lithium-ion batteries were involved in the testing: lithium iron phosphate (LFP) and nickel manganese cobalt oxide (NMC).

Both of these chemistries underwent a series of tests including small-scale, intermediate-scale, and large-scale free-burn fire testing. The smaller-scale tests were helpful in predicting how the large-scale batteries would burn as well as the likelihood of spreading to adjacent exposures. In addition to free burns, this study also conducted large-scale fire testing with an installed wet-pipe sprinkler system to study the effects of the sprinkler system on a lithium-ion battery fire. The final results can be found in the report, but in summation, the two battery chemistries demonstrated significantly different heat output and an ultimately different protection recommendation as shown in Table 1. This reinforces the need for more publicly available test data since it will be difficult to find a one-size-fits-all solution to BESS fires.

Table 1: Recommended Separation of Lithium-ion Battery Energy Storage Systems

First Responder Training

In addition to research and standards development work, NFPA has developed training for first responders that is available online and in person. The goal of this training is to educate first responders on the basics of ESS and solar panels as well as the hazards they can present. This training also addresses tactics and pre-incident planning. NFPA has made this training available for free to first responders. If their jurisdiction includes ESS and/or solar panel, they now have a resource to help them stay safe by adequately preparing and training for these incidents.

Conclusion

With all of the environmental, financial, and infrastructure benefits that a BESS can provide, it is safe to say this technology is here to stay and is being embraced globally. NFPA continues to ensure the availability of reliable information and resources for the community to ensure we continue to enjoy the benefits of new technologies while being prepared for any emergency situations that might occur.

NFPA’s guiding principal is “It’s a Big World. Let’s Protect It Together.” This is not a slogan. It is a call to action for all of us. In this instance, it is a challenge to learn all you can about BESS, the fire protection systems and strategies that can reduce hazards, and the response techniques that will keep buildings, workers, occupants, and first responders safe.

Brian O’Connor, PE, is a Fire Protection Engineer at the National Fire Protection Association (NFPA), where he is the staff liaison to several technical committees covering topics such as aviation, portable extinguishers, water-based fire protection, energy storage systems, and health care facilities. He is also Vice President for the New England Chapter of the Society of Fire Protection Engineers. Brian is a Professional Engineer registered in the states of Texas and Massachusetts. He earned his BS in mechanical engineering from Rowan University and an MS in fire protection engineering from the University of Maryland.

Brian O’Connor, PE, is a Fire Protection Engineer at the National Fire Protection Association (NFPA), where he is the staff liaison to several technical committees covering topics such as aviation, portable extinguishers, water-based fire protection, energy storage systems, and health care facilities. He is also Vice President for the New England Chapter of the Society of Fire Protection Engineers. Brian is a Professional Engineer registered in the states of Texas and Massachusetts. He earned his BS in mechanical engineering from Rowan University and an MS in fire protection engineering from the University of Maryland.