It was late in 2017 when the notice for the Second Draft meeting for the 2019 edition of NFPA 70B, Recommended Practice for Electrical Equipment Maintenance came out, and within the agenda was an item to discuss the 2023 edition. COVID-19 wasn’t even a thought for any of us. Social distancing, masking up, and quarantine were unheard of, and Teams/Zoom video conferencing wasn’t even a thing. (Ahh, the good old days!)

The meeting took place in January 2018 in San Antonio, Texas. Here, public comments were addressed, changes were made, and the document was prepared for the final Second Draft. It was at this point that task groups were formed, sections of the document were placed into a “sunsets” category, and rewriting the just-finalized edition of NFPA 70B began the journey from a recommended practice to a standard.

RECOMMENDED PRACTICE OR STANDARD – WHAT’S THE DIFFERENCE, AND WHY IS IT IMPORTANT?

For many decades, the previous editions of 70B, including the previous 2019 edition, were published as a “recommended practice.” The key point here is to know that a recommended practice does not contain mandatory requirements. It is, by definition, just as it says: a recommendation on how to do things.

Statements such as “should” and “may” are cornerstones of the text within a “recommended practice” document.

With the release of the 2023 edition as a standard, that all changed. A standard is just that: “something established by authority, custom, or general consent as a model or example.” So now, NFPA 70B, as a standard, contains mandatory language for the maintenance of electrical equipment. You will see terms such as “shall” and “will” in the newest version of the document, and it is these actionable terms that make the outcomes mandatory and enforceable. You shall do it!

A MONUMENTAL TASK: THE REWRITE

The task groups proceeded immediately, working on segregating much of the “what to do” from the explanatory material, which proved to be more of a task than many originally thought. From a user’s standpoint, the new text structure and words may take some getting used to. All of the explanatory material has been moved to the Annex, so it was not lost from the original document as it includes material from a plethora of industry experts’ experiences and knowledge. The Annexes include the familiar Reliability Centered Maintenance, Power Quality, Electrical Disaster Recovery, and Sample Forms sections, among other topics.

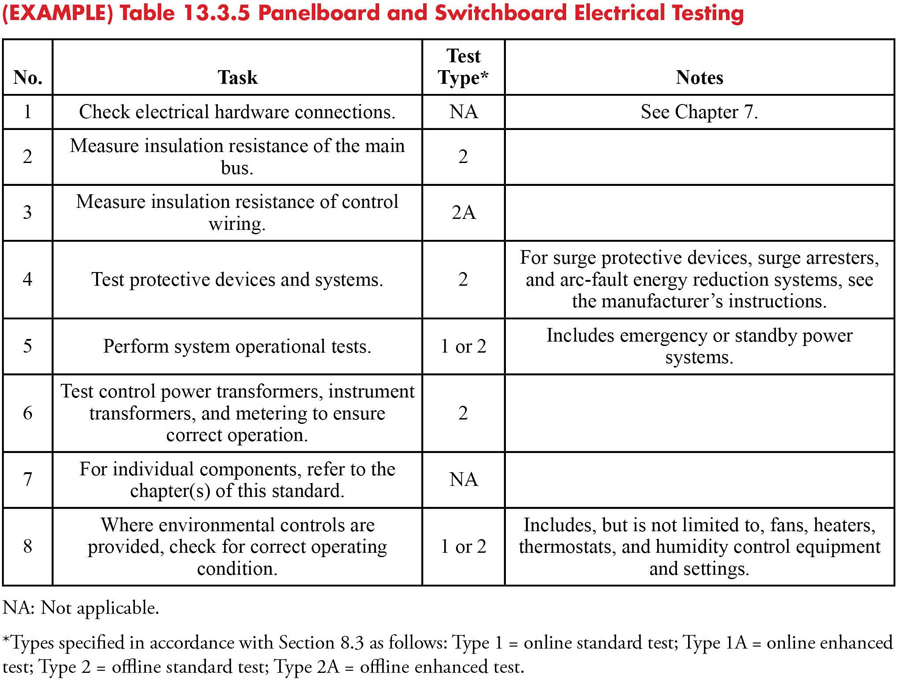

One of the next things to tackle was the formatting of the tests to be performed. Early on, the committee worked together to develop a table where tests would be listed down the Y (vertical) axis and equipment across the X (horizontal) axis. While not all tests would be required for a particular piece of equipment during routine maintenance, some may only be needed when other tests indicate a possible issue but are not conclusive. We differentiated these tests by calling them “enhanced” tests. And while most tests are performed while the equipment is out of service and de-energized, some tests require the equipment to be operating and energized (a thermographic scan, for example).

Because of these testing variables, four testing category types were developed: Categories 1, 1A, 2, and 2A. A Category 1 test is an online standard test. Category 1A is an online enhanced test. Category 2 and Category 2A are the offline counterparts. Placing everything that might be performed on any piece of equipment into one table produced a very large table, so inspections and tests were divided between three tables: Visual Inspections, Mechanical Servicing, and Electrical Testing. Table 13.3.5: Panelboard and Switchboard Electrical Testing provides an example.

Going into 2020, each task group continued their work on various chapters. Bi-weekly, two-hour, web meetings were held, and the 70B committee was fortunate to get accustomed to remote video meetings before COVID arrived as there were many hours of video meetings! This work continued into 2021 and then 2022. Some sessions were definitely easier than others, but some of the later ones were over eight hours long for the entire week. Even through all of that, the committee worked very well together.

After the first draft was published, the public comments had to be addressed. The newly-formed task groups would each review a certain number of public inputs and then present a proposed response to the entire committee.

Moving into a standard also meant certain wording couldn’t be used; for example, wording that was vague, ambiguous, or could have multiple definitions had to be replaced. Each task group began looking for and reworking text that was outside the style manual. Some examples include terms such as “generally,” “likely,” or “mostly.” These are all subjective in nature and will be interpreted differently between individuals — or even between moods for the same individual.

In the end, we ended up with a document that is a standard that promotes the safe operation and maintenance of electrical equipment. Safety is a cornerstone of the document. No maintenance activity should place a worker in harm’s way; that’s certainly never the intent. I recall a presentation regarding safety where the speaker suggested that anyone who holds safety as a first priority is simply wrong; priorities change in a heartbeat, but safety never should. So it’s not a priority, it’s a principle.

SUMMARY

The purpose of NFPA 70B is:

To provide for the practical safeguarding of persons, property, and processes from the risks associated with failure, breakdown, or malfunction and a means to establish a condition of maintenance of electrical equipment and systems for safety and reliability.

And that falls right into what we strive to do as an industry each and every day.

Get your copy of this very important document and read and understand the requirements of the 2023 edition of NFPA 70B, Standard for Electrical Equipment Maintenance at NFPA.org. Print copies will be available after April 14, 2023.

David Huffman has been with Power Systems Testing, a NETA Accredited Company, since January 1988 and is currently CEO. He graduated from California State University, Fresno, and is a licensed Professional Electrical Engineer in the state of California as well as a NETA Level IV Certified Technician. David is a NETA board member, NETA’s Principal Representative to the NFPA 70B Committee, and serves as a member of various NETA committees.

Ron Widup is the Vice Chairman, Board of Directors, and Senior Advisor, Technical Services for Shermco Industries and has been with Shermco since 1983. He is a member of the NETA Board of Directors and Standards Review Council; a Principal member of the Technical Committee on Standard for Electrical Safety in the Workplace (NFPA 70E); Principal member of the National Electrical Code (NFPA 70) Code Panel 11; Principal member and Chairman of the Technical Committee on Standard for Competency of Third-Party Evaluation Bodies (NFPA 790); Principal member and Chairman of the Technical Committee on Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation (NFPA 791); a member of the Technical Committee Recommended Practice for Electrical Equipment Maintenance (NFPA 70B); and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. He is a member of the Texas State Technical College System (TSTC) Board of Regents, a NETA Certified Level 4 Senior Test Technician, State of Texas Journeyman Electrician, a member of the IEEE Standards Association, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).