This article reviews current electrical testing methods and trends in the operational health of electric motors in the context of successful predictive maintenance programs. It explains the concepts of static motor testing — testing a motor that is not running — as well as dynamic motor monitoring, which involves analyzing motors while they are in service or operating within their application environment.

It also introduces an emerging type of online dynamic monitoring involving a permanently installed networked motor analyser that enables maintenance professionals to monitor motor system conditions from any web-accessible computer. The benefits and features of various types of test equipment and motor testing methodologies with regard to conditions that can impact the health of a motor but can be external to the motor itself are discussed.

PREDICTIVE MAINTENANCE

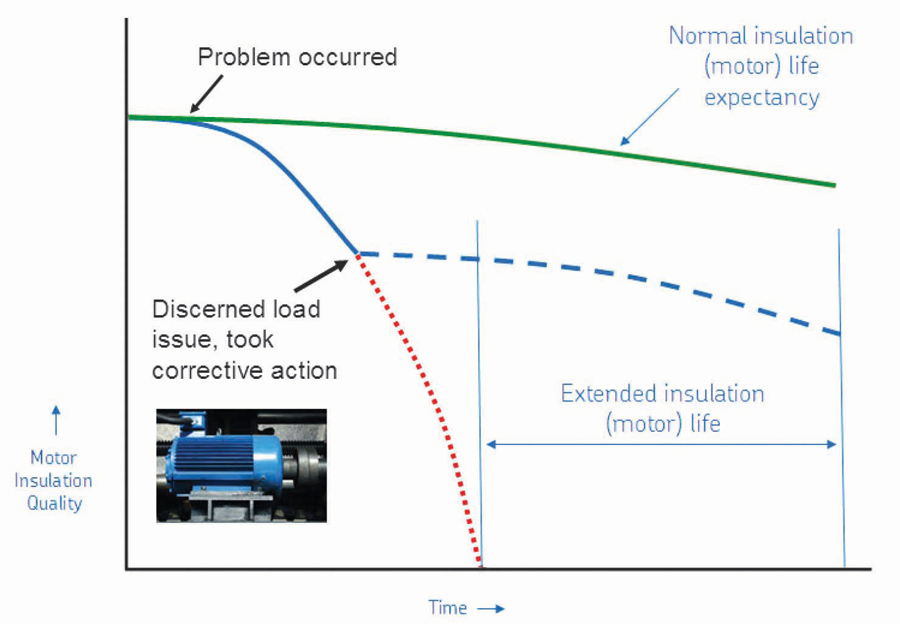

Predictive maintenance programs are crucial to an organization’s ability to avert unplanned or unnecessary downtime that can adversely affect a company’s ability to produce or operate. Unlike time-based or run-to-failure approaches to maintenance management, condition-based programs are ideally geared to pay for the cost of implementation by extending the service life of motors and rotating equipment, averting costly unplanned downtime, and minimizing the costs of replacing expensive equipment. Predictive maintenance programs are most effective when all available means to measure health and analyze health trends of electric motors, cables, power quality, and load are rigorously implemented.

Safe and continuous operation of plants and facilities drives revenue and profit, and it depends upon high motor reliability. Predictive maintenance of motor systems is a necessity when it comes to supporting reliability objectives that in turn support a company’s or organization’s business objectives. The power generation industry ranks at the top of this requirement for uninterrupted operation and safe, continuous production.

Some motors run equipment that is ancillary to the production or health of a company (for example, a rooftop motor for an HVAC system that doesn’t have an immediate impact on the HVAC system if it stops working). Other motors are critical to a company’s ability to conduct business: They are motors that drive such things as conveyor systems, fluid pumps, or production-line machinery that a company relies upon to generate revenue and profit.

The goal of a predictive maintenance program is almost always to reduce unscheduled downtime. An effective predictive maintenance program is measured by how well it works to predict imminent failures and identify potential problem areas before they fail and create expensive recovery costs for an organization. The program should also work to determine the root causes of failures and ultimately save money by extending the service life of motors and rotating equipment. This is why electrical testing of motors is such a critical component of predictive maintenance. Static and dynamic analysis, along with trend data acquisition and analysis, provides the information technicians need to make good decisions regarding the use or maintenance of a given motor.

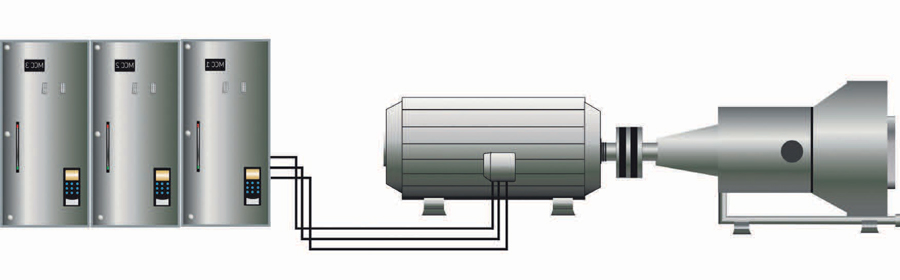

Motor Systems

Motors, whether used to drive conveyors, pumps, cooling fans, or any other machinery, are best viewed as core parts of a system. These are often referred to as motor systems or sometimes machine systems and include the motor, the source of the motor’s power, and the equipment or machinery driven by the motor (Figure 1).

Electric motor test equipment today is generally categorized into two types: static motor test equipment and dynamic motor test equipment. The static motor test is capable of simulating real-world situations when motors are off-line. Dynamic motor test equipment is used to safely acquire accurate and valuable health data across a working motor system or a motor’s in-service environment.

Static Motor Testing

Static motor test data provides visibility into the integrity and condition of a motor’s insulation and motor circuit. Modern equipment can help maintenance technicians predict or identify imminent failures before they cause costly unplanned downtime of motors and the rotating machinery they support. The most effective static test equipment is capable of testing the components of motors at voltage levels similar to those the motor will see in its normal operation without destructive currents.

Static testing should include the surge test, which is the most effective method to ensure the integrity of a motor’s turn-to-turn insulation. The best static motor analyzers produce trend logs and reports that allow technicians to track any decline or degradation of a given motor’s health.

Dynamic Motor Testing

The latest dynamic test equipment can locate and identify problems that adversely impact motor health and motor life that are on either side of the motor within the motor system. These are generally power-related issues and load problems but can include vibration or circuit condition problems within a motor while the motor is in service.

Dynamic motor analyzers can calculate speed and torque, define rotor bar problems, and measure distortion. Dynamic motor testing can also identify mechanical issues such as bearing problems or motor shaft misalignment. Dynamic testing helps isolate mechanical (system) issues from electrical (internal to the motor) issues while providing valuable information to discern the root causes of motor failures.

Off-Line Testing

Static testing (off-line testing of motors in their static, powered-down state) is commonly performed just once in a given period of months, usually up to a year or more. It’s also performed opportunistically during outages when a motor is shut down for other reasons.

Off-line testing is often used as a quality assurance measure when receiving new, reconditioned, or rewound motors from a supplier or motor shop. This is to assure they work as expected before they are stored or returned to service. Testing these motors proves the motor shop is doing its job properly and creates new baselines for future trend analysis.

TEST EQUIPMENT

Static motor test equipment can troubleshoot motor problems or failures. Any time a problem occurs, the motor involved should first be tested for insulation integrity. Out-of-spec voltages, motor loads, and contaminants are examples of problems that can adversely impact a motor’s internal insulation. Typical static tests include winding resistance, insulation resistance (IR), polarization index (PI), DC step voltage, and surge testing. These tests should be performed in that sequence with modern, state-of-the-art test equipment. Surge-test analyzers can reproduce real-world experiences without causing damage to a motor’s insulation system and underscore the importance of testing motors at the voltage levels and conditions a motor experiences in normal, everyday operation.

Winding resistance tests confirm that a motor’s phases are balanced; they detect shorts and opens in the motor’s windings as well as high, out-of-spec resistance connections. A static insulation resistance test can determine whether the motor’s windings are grounded or contaminated. The IR meter is probably the most-used test instrument in the field but it has its limitations. IR testing is usually performed at voltages slightly above line voltage.

It is important to note that an insulation resistance test can determine if a motor is bad, but it cannot confirm the motor is good. Low results are an indication of impending failure, but high values do not ensure that a motor is free of other faults. A polarization index (PI) test can also confirm poor/degraded insulation within a motor, but while it can indicate when a motor’s insulation is old and brittle, it does not find potential turn-to-turn faults.

A DC step-voltage test involves exposing the entire winding to voltage equal to that commonly seen at start-up or shut-down. It looks for weak ground-wall insulation. Weak or damaged cable problems can also show up during this test, and it may be necessary to separate the motor at its junction box in order to determine the root cause of the problem. DC step-voltage testing is commonly performed at double the line voltage plus an additional 1,000 volts but has no adverse impact on the motor or motor insulation when properly applied.[1]

Lastly, once a motor has passed all the other tests, a surge test should be applied. Surge testing is the only way to locate weak turn-to-turn insulation. These copper-to-copper faults are the primary cause of more than 80% of all winding-related failures, and they would go undetected if not for the surge test. Most motors, when allowed to run to failure, will blow to ground in a slot. That is because a slot provides a ready path to steel, but most such shorts will have started as a copper-to-copper/turn-to-turn fault.[²] Locating weak insulation areas before they become hard-welded faults allows a maintenance professional time to plan for repairs before a catastrophic failure causes unscheduled downtime, expensive repairs, and lost production. Once these turn-to-turn faults have become hard-welded faults, a motor typically only has about 15 more minutes of service life.

On-line (dynamic) monitoring

Dynamic or on-line monitoring is performed while the motor is powered on and working within its normal system or application. Data collection using dynamic motor testers is safe, fast, and nonintrusive. Dynamic testing provides information regarding power quality and conditions such as voltage levels, unbalances, and distortion. A small amount of voltage unbalance coupled with minor harmonic voltage distortion may result in a NEMA (National Electrical Manufacturers Association) de-rating that will not be seen with simple multimeters and amp probes. Current levels and current unbalances also affect motor performance, so monitoring them is essential when trending motor health.

Dynamic testing can and should be performed more often than off-line testing at a frequency similar to vibration analysis. The concept is relatively new compared to static testing, but it has rapidly emerged as a common, standard condition monitoring approach.

In addition to monitoring electrical issues, data collected using dynamic testing technology can discern mechanical issues. A good dynamic analyzer provides relevant condition information about all three motor/machine system components: power source, load source, and the motor itself. Monitoring conditions such as voltage levels, unbalances, and distortion that affect motor performance is essential for analyzing motor health trend data.

Many motor problems are created by adverse or mismatched loads or by poor supply power. Torque and current spectra have proven to be highly useful in determining mechanical issues, including bearing faults, looseness (vibration or misalignment), and eccentricity.

Without a way to analyze data from monitoring across a motor system, the true root cause of motor failure often goes undetected. The ability to acquire and define such adverse impacts as torque anomalies provides the means to separate mechanical issues from electrical issues, improve decision-making concerning repair or replacement, and otherwise extend the service life of the motor (Figure 2).

Another challenge with electric motors is tracking rotor condition. Today’s dynamic motor analyzers help predict rotor bar failures or potential failures if the load is relatively steady. A pump, fan, or blower operating at a steady frequency will show very clear rotor bar signatures that make rotor fault diagnoses easier than ever before. During normal operation, a motor’s rotor is stressed by its load. Torque waveform analysis provides a picture of those stresses, and when they reach levels out of spec for the motor, they can indicate a number of mechanical problems. Cavitations and belt flapping, for example, are easily seen in a torque waveform signature. Motor analyzer manufacturers continue to improve on the ability of test equipment to discern mechanical motor system issues earlier and with greater accuracy.

STATIC AND DYNAMIC TESTERS

Nearly all modern static and dynamic testers are portable. Static testers can be used in a shop or easily carried into the field. Dynamic testers are by nature used in the field (wherever running motors are located) but often test via a motor-control center (MCC). However, emerging new technology has spawned a dynamic motor analysis tool that is permanently installed in proximity to the locations of up to 32 motors via motor busses within MCCs. The concept is to perform all of the same tests a portable dynamic motor tester does, but with the additional benefits of continuous monitoring and the ability to view the status of a given motor from a central office location — anywhere in the world with a PC and a good Internet connection.

This new technology enables maintenance professionals to make better decisions faster than the spot-testing method of testing characterized by route-running once every few months to yearly. It captures information that can’t otherwise be captured in a single testing session performed with a portable tester. Alerts can be set to flag maintenance professionals to the need to investigate and/or replace critical motors. Moreover, the trend data from months of monitoring provides valuable insight that informs predictive maintenance planning and helps prioritize resources and actions. Finally, because the monitoring is effectively performed remotely, online dynamic analyzers all but eliminate safety hazards associated with testing in-service motors in the field.

Dynamic monitoring also provides efficiency information that allows maintenance professionals to make wise and practical decisions when confronted with choices to repair or replace a given motor. Improving efficiency by just 2% can result in thousands of dollars in excessive annual energy costs.

CONCLUSION

Static and dynamic testing of electric motors is critical for successful implementation of predictive maintenance programs. Static testing is the most effective means of measuring the integrity of the motor’s insulation system, and it also can be used for quality assurance when a motor is out of service.

Dynamic testing provides valuable information about motor systems, including power condition, load, and the motor, including physical aspects that can affect the life or operation of the motor. Online motor monitoring adds the dimension of gathering motor system health data at regular intervals throughout the day, 365 days a year. Combined, the data presents a comprehensive picture of motor and motor system health that can be the foundation for a successful predictive maintenance program. Because it provides the full spectrum of motor condition information required to accurately diagnose and predict imminent failures, electrical motor testing’s place as an essential part of a complete predictive maintenance program is solidified.

REFERENCES

[1] B. K. Gupta, G. C. Stone, J. Stein. “Use of Machine Hipot Testing in Electric Utilities,” Proceedings: Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference (Cat. No.01CH37264), 2001, pp. 323-326,doi: 10.1109/EEIC.2001.965645. [2] R.M. Tallam, T.G. Habetler, R.G. Harley. “Transient Model for Induction Machines with Stator Winding Turn Faults.” IEEE Transactions on Industry Applications, Vol. 38, No. 3, May/June 2002.

Drew Norman has worked as anApplications Support Engineer and product training lead at Megger Baker Instruments for 14 years. He previously was with General Electric in a variety of roles. Drew trained and served in the U.S. Navy for eight years as a Journeyman Electrician and Nuclear Operator in the submarine service. Drew is a senior at Colorado State University working toward a BS in computer science specializing in machine learning and artificial intelligence. He is qualified as a Level III Vibration Analyst through Technical Associates and a Level I Thermographer through CSI, and is a Level III Baker Analyst/Instructor.