The 2021 NFPA 70E cycle started last year, and the Second Draft Meeting will convene July 14–19, 2019. One interesting benefit of being on the committee is the information that is shared with us. Some of it is obviously presented to serve one purpose or another, but some of it is put forward by well-known, independent laboratories that have no reason to slant things.

One such piece of information was presented by Bonneville Power Administration (BPA) in their Engineering and Technical Services Report, BPA F5450.05. This report covers incident energy tests done on a 125V, 1,300-ampere-hour battery bank. BPA is part of the United States Department of Energy and is well-respected for their studies on testing and maintenance of field equipment, as well as other subjects. The 90-page report is too long to publish in this column, but anyone can request a copy from Jim White at jwhite@shermco.com.

This column shares the conclusions they reached by testing the subject battery bank and tries to clear the air a bit, as a number of NETA-member technicians have concerns about working on battery systems. The report is dated May 2017, so it is fairly recent.

In the Beginning

The report was initiated by BPA’s Protection Engineering Group (TECC) to validate the models they were using for dc incident energy calculations and to provide guidance for reducing the exposure of its technicians. Previously, they had performed some testing at 48Vdc and 125Vdc using small (nine-ampere-hour) batteries. These earlier tests indicated that many of their dc panels had high estimated incident energy and required restrictive personal protective gear to work on or near. In these earlier tests, an arc could be sustained at 125V, but not at 48V. Incident energy at 48V was negligible due to the small capacity of the battery.

The tests provided some information, but BPA wanted to perform tests closer to the actual conditions its technicians would face in the field. Therefore, this new series of tests was conducted.

Here and Now

The tests were performed using a 125V, 1,300-ampere-hour battery bank with a bolted fault current of 11,000A. The tests were performed at 3,900A and 7,850A of fault current. Sixty tests were run, and the arc duration, peak current, mean arc current, and incident energy at 18 inches were all recorded, including the waveforms.

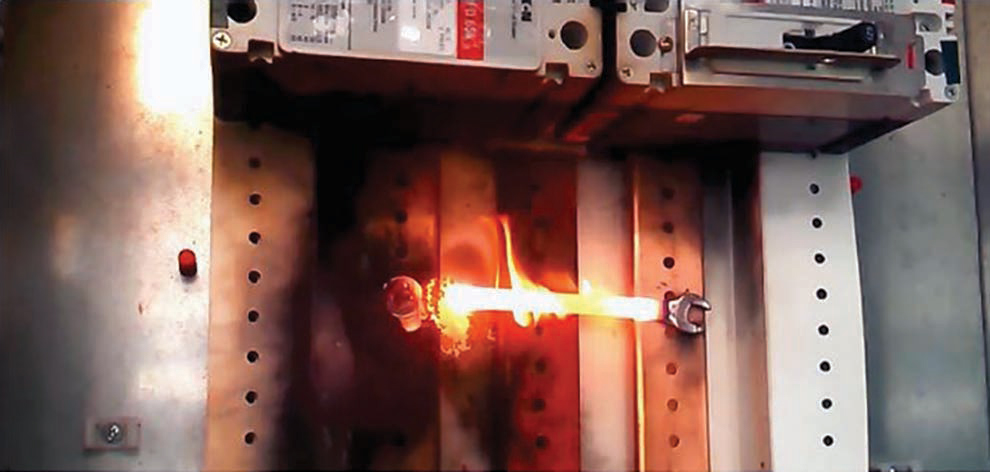

According to the report, changing to the full-size battery bank actually made the arc more difficult to sustain due to magnetic forces that caused the arc to move and expand rapidly. The difficulty in sustaining the arc was also caused by erosion of the metal, which widened the arc gap and extinguished the arc. Between the two factors, arc duration and incident energy were reduced.

The highest fault current was measured at 7,850A, and the greatest arc duration was 0.715 seconds. The highest incident energy (at 18 inches) measured 0.9 Cal/cm2. To us, this is surprisingly low. BPA notes that their previous estimates on incident energy were 10 times what these tests indicated. With that much difference in estimated incident energy, technicians would surely wear much more arc-rated PPE, maybe unnecessarily. The testing to investigate reducing incident energy exposure to their workers was not followed through, as the tests did not provide justification.

BPA Report Summary

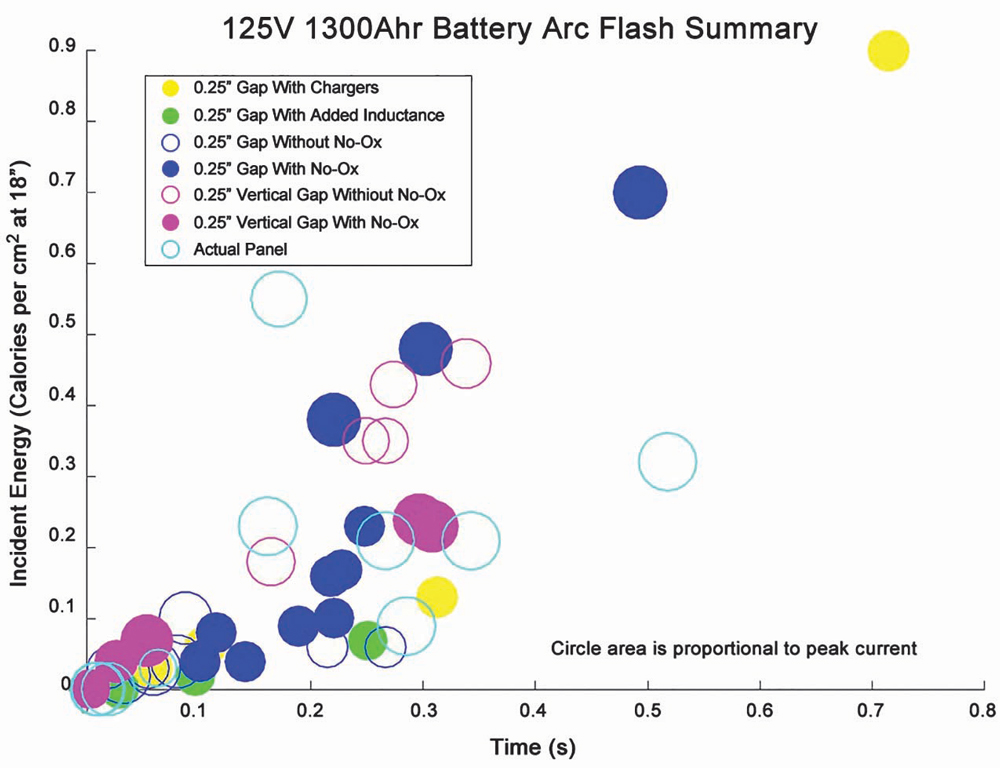

The dc arc flash test results using the 125V 1,300-ampere-hour battery are summarized here.

- Bolted fault currents of 3,900A and 7,850A were achieved.

- An arc can be reliably initiated with bus bar spacing of .025 inch and 0.5 inch. Gap spacing larger than 0.5 inch results in a very short arc duration.

- It is difficult to sustain an arc with this source. Once established, the arc rapidly moves to a place where it can expand and extinguish itself. When forced into a confined area, it erodes the copper (or steel) electrodes until there is sufficient gap to extinguish the arc.

- The longest arc time observed was 0.715 seconds. This is significantly shorter than the standard two-second arc duration used in arc flash calculations.

- The measured incident energy at 18 inches was modest. The maximum measured incident energy was 0.9 Cal/cm2. This is considerably less than models would predict (10.3 Cal/cm2).

- Molten metal is ejected from the arc and presents a hazard to personnel in close proximity to the fault.

- Tests with a tool in the gap did not produce significant incident energy levels. Loose tools were quickly ejected from the test bus without excessive force. When the tool was fixed into place, the resulting arc eroded the tool and bus bar until the gap was wide enough to extinguish the arc.

- Test results with battery chargers are consistent with standard assumptions that they contribute up to 150 percent of their maximum current rating.

- Adding inductance to the circuit did not result in a significant increase in arc duration.

Results with a Tool in the Gap

- In most cases, combustible materials in the gap extend the arc duration and thereby the incident energy.

- Arc detection and mitigation schemes are not worth pursuing due to the low incident energy levels observed.

When BPA used a tool to bridge the two bus bars, it was ejected immediately without excessive force. I guess that means it didn’t become a weapon. A maximum of 0.8 Cal/cm2 was measured during these tests. When the tool was fixed to one bus and touching the other, it burned away the end of the tool and the bus until there was adequate gap to extinguish the arc. The maximum incident energy measured was 0.32 Cal/cm2.

The Bottom Line

BPA provides all the test results in the report. However, more important for most NETA members are the graphs included in the report.

In Figure 1, the highest incident energy recorded (18 inches from the arc source) was 0.9 Cal/cm2; other tests were measured at almost 0.8 Cal/cm2 and 0.6 Cal/cm2. The rest of the results were less than 0.6 Cal/cm2.

Figure 1: Incident energy was measured at 0.25-inch gap, with and without No-Oxide® used to prevent corrosion of the terminals.

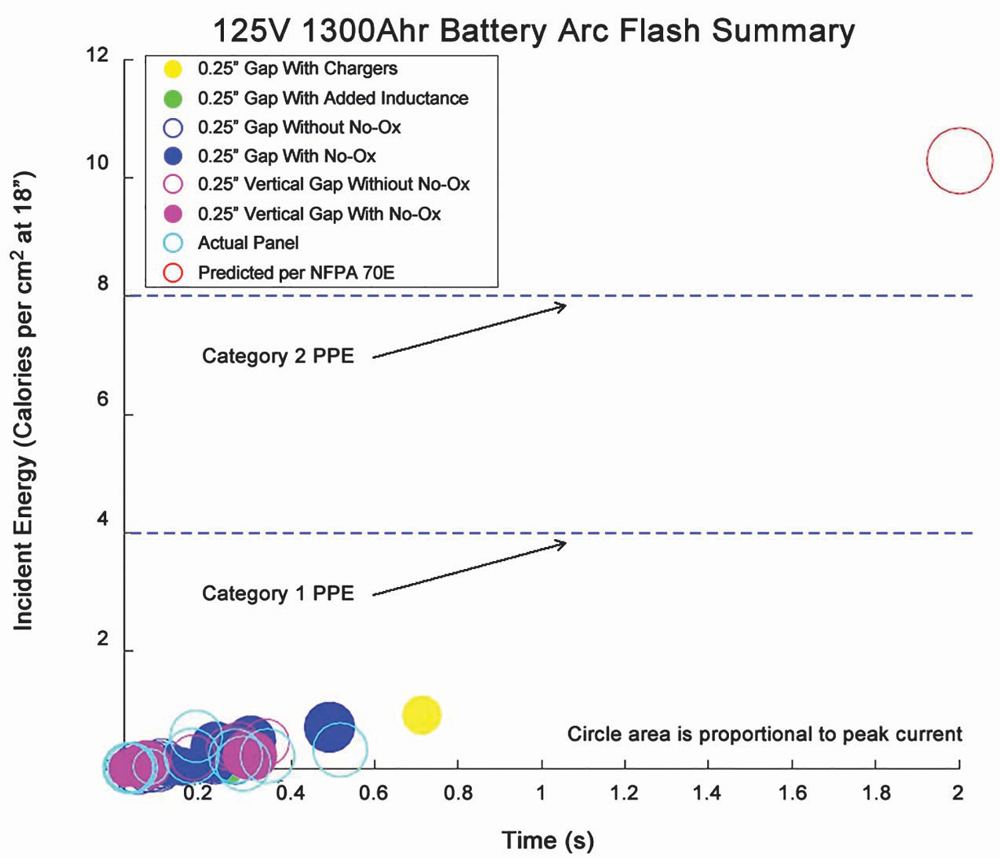

In Figure 2, these measured values are compared to the calculated values plus Category 1 (4 Cal/cm2) and Category 2 (8 Cal/cm2) arc-rated clothing. Note the calculated value is a bit above 10 Cal/cm2.

Figure 2: Measured vs. Calculated Values and Category 1 PPE

Conclusion

The test results provided by BPA’s testing are interesting and raise questions about dc arc flash calculations provided by NFPA 70E. Although ac arcs are fairly well researched, dc arcs are not. More clarity should be brought to light when the IEEE/NFPA Joint Work Group publishes its results, but who knows how long that will take.

In the meantime, you have to make your own decisions about how to treat dc arc flash. You can use the results of BPA’s report, or you can be more conservative (much more conservative according to BPA) and use the calculations in NFPA 70E. Or you could use something between the two. In the end, we’re discussing personnel safety, and your company would be responsible.

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E, Electrical Safety Requirements for Employee Workplaces. Both gentlemen are employed by Shermco Industries in Dallas, Texas, a NETA Accredited Company.

Ron Widup is CEO of Shermco Industries and has been with the company since 1983. He is a member of the Technical Committee on NFPA 70E, Standard for Electrical Safety in the Workplace; a Principal Member of the National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; and a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation. Ron is also a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and a member of the NETA Board of Directors and Standards Review Council. He is Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron is a Journeyman Electrician in Texas, a NETA Level 4 Senior Technician, and an NFPA Certified Electrical Safety Compliance Professional.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Standard for Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Standard for Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.