This issue of NETA World continues with the deep dive into the NFPA 70E revisions that went into the 2021 edition. Part 1 in the Winter 2020 issue covered the reorganization (which was not nearly as extensive as in previous editions); reviewed Article 100 Definitions; and began on Article 110 General Requirements for Electrical Safety-Related Work Practices with Section 110.1 Priority.

As we continue with this Part 2 article, we look at Article 110 and Article 130. As in Part 1, revisions are shown in legislative text: Deleted language is shown red and crossed through; added text is shown black and underlined.

Article 110 Revisions (continued from Part 1)

120.2(A) Lockout/Tagout Principles (A), General, was moved to 110.2, along with its Informational Note. The Committee Statement explains the reasoning well:

The requirements found in 120.2 Lockout/Tagout Principles (A) General are relocated to Article 110 as these requirements are general in nature and are more appropriate for this section of the document. The relocated text is placed at 110.2 so as to create a logical progression of requirements.

Locating the requirement to de-energize in Article 110 prioritizes and emphasizes the requirement: the requirement to de-energize is a requirement of an Electrical Safety Program; the requirement to de-energize should be located before lockout requirements; and Article 130 can be focused on requirements related to work involving an electrical hazard.

This just made sense, as did relocating Section 105.4 Priority to Section 110.1.

130.2 Electrically Safe Work Condition was moved to 110.3 and was unrevised. The remainder of 130.2 was moved to 110.4 Energized Work, which comprises:

- 110.4(A) Additional Hazards or Increased Risk

- 110.4(B) Infeasibility

- 110.4(C) Equipment Operating at Less Than 50 Volts

- 110.4(D) Normal Operating Condition

All these revisions were made to create a logical progression of requirements. We know many 70E users felt the order of sections was fine the way it was, but as we get accustomed to the new order, we will see the benefits of the new organization.

110.1 Electrical Safety Program is now 110.5. 110.5(A), General was revised and now reads:

The employer shall implement and document an overall electrical safety program that directs activity appropriate to the risk associated with electrical hazards. The electrical safety program shall be implemented as part of the employer’s overall occupational health and safety management system, when one exists.

The deleted sentence was removed because it did not add anything to the first sentence.

No changes were made to Informational Note 1, Informational Note 3, and Informational Note 4 in Section 110.5(A). However, Informational Note # 2 was revised to read:

Informational Note No. 2: ANSI/AIHA Z10, American National Standard for Occupational Health and Safety Management Systems , provides a framework for establishing a comprehensive electrical safety program as a component of an employer’s occupational safety and health program. See Informative Annex P for information on implementing an electrical safety program within an employer’s occupational health and safety management system.

The first sentence of Informational Note No. 2 was not in the correct location, and it interfered with the last sentence. Generally, 70E refers users to Informational Annexes without including other sentences in the same Informational Note.

110.5 Electrical Safety Program is structured the same as 110.1 was in the 2018 edition of NFPA 70E. Most of the following revisions are self-explanatory:

- 110.5(A) General. The revisions made in this sub-section have been discussed.

- 110.5(B) Inspection. No revisions.

- 110.5(C) Condition of Maintenance. No revisions.

- 110.5(D) Awareness and Self-Discipline. No revisions.

- 110.5(E) Electrical Safety Program Principles. No revisions.

- 110.5(F) Electrical Safety Program Controls. No revisions.

- 110.5(G) Electrical Safety Program Procedures. No revisions.

- 110.5(H) Risk Assessment Procedure.

- 110.5(H)(1) Elements of a Risk Assessment Procedure.

The risk assessment procedure shall address employee exposure to electrical hazards and shall identify the process to be usedby the employeebefore work is started to carry out the following:

(1) Identify hazards

(2) Assess risks

(3) Implement risk control according to the hierarchy of risk control methods

Informational Note No. 1: The risk assessment procedure could include identifying when a second person could be required and the training and equipment that person should have.

Informational Note No. 2: For more information regarding risk assessment and the hierarchy of risk control, see Informative Annex F.

Informational Note No. 2 of Section 110.5(H)(1) is a good example of the way Informational Annexes are referred to in 70E. Figure 1 shows a safety backup as referred to in 110.5(H)(1) Informational Note No. 1.

- 110.5(H)(1) Elements of a Risk Assessment Procedure.

Figure 1: Safety Backup

-

- 110.5(H)(2) Human Error.

The risk assessment procedure shall address the potential for human error and its negative consequences on people, processes, the work environment, and equipment relative to the electrical hazards in the workplace.

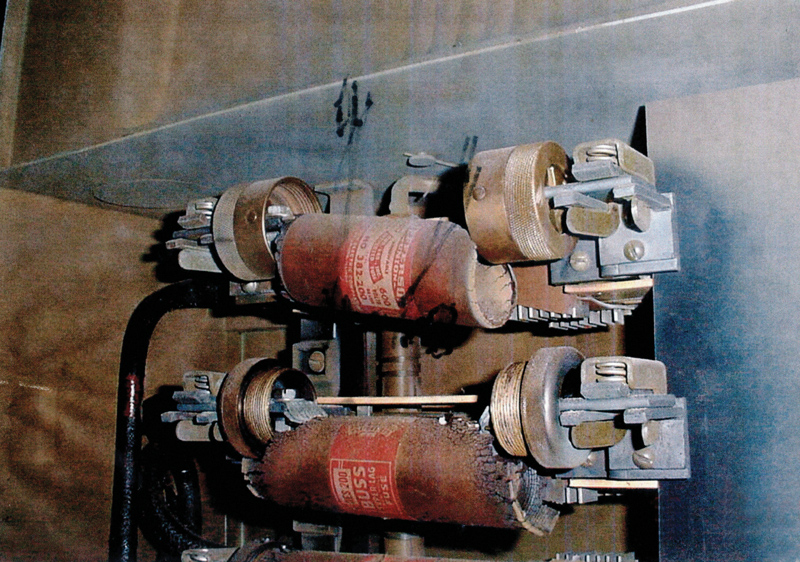

Figure 2a and Figure 2b are good examples of human error that could cause a technician injury or death without it being their fault. Remember that human error could be someone else’s error, not yours. Always do a professional job.

- 110.5(H)(2) Human Error.

Figure 2a: Result of Poor Maintenance — a Form of Human Error

Figure 2b: 400 A Fuse Elements in 200 A Fuses

-

- 110.5(H)(3) Hierarchy of Risk Control Methods.

Informational Note No. 2: See Informative Annex F and ANSI/AIHA Z10, American National Standard for Occupational Health and Safety Management Systems, for more information regarding the hierarchy of risk control methods and examples of those methods.

Informational Note No. 3: The risk assessment procedure could include identifying when a second person could be required and the training and equipment that person should have.

Informational Note No. 4: For an example of a risk assessment procedure, see Informative Annex F.

- 110.5(H)(3) Hierarchy of Risk Control Methods.

- 110.5(I) Job Safety Planning and Job Briefing

- 110.5(I)(1) Job Safety Planning. No revision to text, but a new Informational Note.

Informational Note: For an example of a job safety planning checklist, see Figure I.2. - 110.5(I)(2) Job Briefing

- 110.5(I)(3) Change in Scope. No revisions to text, but revision to Informational Note.

Informational Note: For an example of a job briefingform and planningchecklist, see Figure I.1.

- 110.5(I)(1) Job Safety Planning. No revision to text, but a new Informational Note.

- 110.5(J) Incident Investigations. No revisions.

- 110.5(K) Electrically Safe Work Condition Policy. New Sub-Section.

An electrical safety program shall include an electrically safe work condition policy that complies with 110.3.

The Committee Statement on this revision is worthwhile:

The new subsection 110.5(K) requires that employer’s electrical safe work program include a policy on establishing an electrically safe work condition. This correlates with the requirement in Article 120 and provides clarity by ensuring it becomes part of the employer’s electrically safe program. - 110.5(L) Lockout/Tagout Program. New Sub-Section.

The electrical safety program shall include information required by one of the following:

(1) A lockout/tagout program in accordance with 120.1(A)

(2) A reference to the employer’s lockout/tagout program established in accordance with 120.1(A)

Up to this edition, there had been no specific requirement for a LOTO program in the electrical safety program. 120.1(A) General required a documented LOTO program (Figure 3a and Figure 3b). but did not state where it had to be. This Sub-Section corrects that oversight.

Figure 3a: Proper Lockbox LOTO at a Large Shutdown

Figure 3b: Improper LOTO

- 110.5(M) Auditing. No revisions in Section or Sub-Sections.

- 110.5(M)(1) Electrical Safety Program Audit

- 110.5(M)(2) Field Work Audit

- 110.5(M)(3) Lockout/Tagout Program and Procedure Audit

- 110.5(M)(4) Documentation

- 110.6 (moved from 110.2 Training Requirements) Electrical Safety Training

- 110.6(A)(1) Qualified Person. Revisions made to Sub-Section.

a. No revisions

b. No revisions

c. No revisions

(1) No revisions

(2) No revisions

(3) Change Table references from 130.4(D)(a) and 130.4(D)(b) to 130.4(E)(a) and 130.4(E)(b)

(4) Only revision is to (d):

d. Select the appropriate risk control methods from the hierarchy of controls identifiedin110.5(G)110.5(H)(3), includingpersonal protective equipmentPPE.

d. No revisions

e. No revisions

f. The employer shall determine through regular supervision or through regular inspections conducted on at least an annual basis that each employee is complying with the safety-related work practices required by this standard. This sub-section was deleted during the First Draft, then reinstated during the Second Draft. - 110.6(A)(2) Unqualified Persons. No revisions.

- 110.6(A)(3) Additional Training and Retraining

RetrainingAdditional training and Retraining in safety-related work practices and applicable changes in this standard shall be performed at intervals not to exceed 3 years. An employee shall receive additional training (or retraining) if any of the following conditions exist: - 110.6(A)(4) Only revision was to change reference from 110.2(A) to 110.6(A)

- 110.6(A)(5) Only revision was to change reference from110.2(A) to 110.6(A)

110.2(B)110.6(B) Lockout/Tagout Procedure Training

(1) Initial Training

Employees involved inor affected bythe lockout/tagout procedures required by 120.2(B) shall be trained….

Some readers may think the deletion of “or affected by” would be a mistake, but the Committee statement clarifies the reasoning behind the revision:

The phrase “or affected by” is deleted. While all employees must understand the purpose of a lockout, the requirement to train employees that are involved in the lockout is consistent with the requirement in 120.2(B) Employee Involvement: “Each person who could be exposed directly or indirectly to a source of electrical energy shall be involved in the lockout/tagout process.

The Committee thought the deleted phrase was inconsistent and not needed.

- 110.6(A)(1) Qualified Person. Revisions made to Sub-Section.

- 110.7 Host and Contract Employer’s Responsibilities. Sub-Section 110.3 was renumbered to 110.7 Documentation, and a new Informational Note was added:

Informational Note to 110.7: On multi-employer work sites (in all industry sectors), more than one employer can be responsible for identifying hazardous conditions and creating safe work practices.

The Committee Statement provides some insight to the new Informational Note:

Although the informational note is located after 110.7(C), it applies to all of 110.7, not just 110.7(C). This revision provides clarity. - 110.8(A) Test Instruments and Equipment. Testing was renumbered from 110.4(A):

Only qualified persons shall perform tasks such as testing, troubleshooting, and voltage measuring on electrical equipment operating at voltages equal to or greater than 50 volts where an electrical hazard exists.

The Committee Statement explains the reasoning for this revision:

The requirement was revised to apply to all electrical hazards, as testing and troubleshooting that involves any electrical hazard, not just a shock hazard, should be performed by a qualified person. - Sub-Section 110.9 Portable Cord-and-Plug-Connected Equipment. This sub-section was renumbered from 110.5 with a few revisions:

110.9 This section applies to the use of cord- and plug-connected equipment, including cord- and plug-connected test instruments and cord sets (extension cords).

This one is pretty clear as to why the addition was made.- 110.9(C) Visual Inspection and Repair of Portable Cord- and Plug-Connected Equipment and Flexible Cord Sets

(a) Frequency of Inspection

Exception: Stationary cord- and plug-connected equipment and flexible cord sets (extension cords) that remain connected once they are put in place and are installed such that the cord and plug are not subject to physical damage during normal use shall not be required to be visually inspected until they are relocated or repaired (Figure 4).

- 110.9(C) Visual Inspection and Repair of Portable Cord- and Plug-Connected Equipment and Flexible Cord Sets

Figure 4: Unsafe Extension Cord

-

- 110.9(D) Conductive or Wet Work Locations. Portable cord- and-plug-connected electric equipment used in

highlyconductive or wet work locations(such as those inundated with water or other conductive liquids)shall be approved for use in those locations. Injobwork locations where employees are likely to contact or be drenched with water or conductive liquids, ground-fault circuit-interrupter protection for personnel shallalsobe used.

- 110.9(D) Conductive or Wet Work Locations. Portable cord- and-plug-connected electric equipment used in

- A new Sub-Section 110.12 Equipment Use was added. This statement is mandatory for almost all equipment and tools used by electrical workers.

- Equipment shall be used in accordance with the manufacturer’s instructions.

Summary

We were able to make it through Article 110 in Part 2, which wore us out, but hopefully not the readers of this column. We hope that detailing the revisions made to Article 110, along with the explanations, will further your understanding of this very important standard. All of us in the electrical field face hazards each and every day, and NFPA 70E goes a long way to help us all diminish the risks.

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E, Electrical Safety Requirements for Employee Workplaces. Both gentlemen are employed by Shermco Industries in Dallas, Texas, a NETA Accredited Company.

Ron Widup, Senior Advisor, Technical Services and Vice Chairman of the Board of Directors, has been with Shermco Industries since 1983. He is a member of Technical Committee on NFPA 70E, Electrical Safety in the Workplace; a Principal Member of National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation; a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron also serves on NETA’s board of directors and Standards Review Council. He is a NETA Certified Level 4 Senior Test Technician, a State of Texas Journeyman Electrician, an IEEE Standards Association member, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

Ron Widup, Senior Advisor, Technical Services and Vice Chairman of the Board of Directors, has been with Shermco Industries since 1983. He is a member of Technical Committee on NFPA 70E, Electrical Safety in the Workplace; a Principal Member of National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation; a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron also serves on NETA’s board of directors and Standards Review Council. He is a NETA Certified Level 4 Senior Test Technician, a State of Texas Journeyman Electrician, an IEEE Standards Association member, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.