Previously, we discussed a 15 kV feeder fault at a manufacturing plant and how NFPA 70E is an important tool for the electrical worker to use in the field as they troubleshoot, repair, and restore the equipment to get the facility up and running.

Faulted 15 kV Equipment

To recap, here’s what happened:

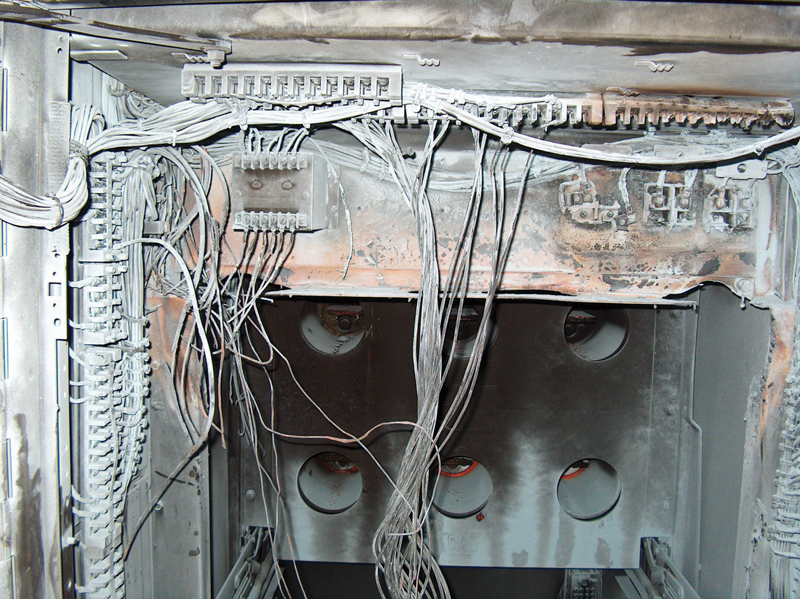

The main circuit breaker in one of the plant’s three medium-voltage substations experienced a fault, arc flash event, and subsequent trip of the entire lineup, apparently due to a rodent that caused a phase-to-phase fault in the 15 kV potential transformer (PT) compartment. The fault traveled into the medium-voltage bus assembly in the metal-clad switchgear lineup, ultimately causing the main breaker to trip and de-energizing a large portion of the facility.

We also highlighted that before work begins, you need to assess the risk. You also need to apply several principles of safe work practices before you begin — principles such as:

- Identify the hazards and minimize the risks [done].

- Establish an electrically-safe work condition [done].

- Protect employees, both workers on the project and other bystanders.

- Plan all the tasks to be performed.

- Anticipate unexpected events, and have a plan to deal with them.

- Ensure the qualifications and abilities of anyone working on the project.

- Determine the condition of maintenance of the electrical equipment.

- Use correct tools and appropriately rated portable meters.

In the first article, we made it through point 1 and point 2. We will now cover points 3 through 6. For the entire Part 1 article, please see the Summer 2021 NETA World at

www.netaworldjournal.org/key-points-of-nfpa-70es-safe-work-practices/.

POINT 3: PROTECTING BYSTANDERS AND WORKERS

The smoke has cleared, and people are showing up to the scene to see what happened and to lend a hand. Some have a legitimate reason to be there, others do not. What should you do?

Key Point — Article 130.7(E) Alerting Techniques

First, set up alerting techniques and barricade the area to keep unauthorized personnel out of the repair worksite. After a significant electrical fault event, temporary or partial power is typically restored, and the affected area contains various physical and electrical hazards. It’s important to keep away people who may not have a grasp on all of the hazards that now exist.

Barricades keep unauthorized personnel out of the work area.

What should you use? Take advice from NFPA 70E, as it provides excellent guidance on alerting techniques and equipment barricading. If you study Article 130.7(E), you will find guidance on:

- Safety signs and tags

- Barricades

- Attendants

Key Point — Article 130.7(F) Look-Alike Equipment

Something that happens time and time again is confusion around look-alike equipment. Think about it: When facilities, especially large facilities, are built, the electrical equipment is often purchased from one manufacturer and is commonly supplied as the same type, style, and ratings.

Place four, five, or even 20 switchboards or substations in a facility, and it all looks the same. Now, take a portion of that equipment out of service to work on it, and it becomes very easy to confuse the de-energized equipment from the energized equipment. NFPA 70E recognizes this and specifically addresses it in 130.7(F) Look-Alike Equipment.

Look-alike equipment can become a blur.

POINT 4: PLANNING THE TASKS

We know what happened. We know what needs to be done to repair the faulted equipment. But to do it safely and efficiently, you need to have a plan.

Faulted equipment remediation requires extra attention to job planning and communication.

Key Point — Informative Annex I: Job Briefing and Job Safety Planning Checklist

One of the best ways to get guidance on the many considerations of job safety is to utilize information found in 70E’s Informative Annex I. Not only are you required, per 110.5(A), to implement and document an overall electrical safety program (ESP), but job briefings must also be included in the ESP elements.

Before starting each job, the person in charge must conduct a job briefing. In situations such as this with a faulted main-breaker cubicle, severe arcing and smoke damage, and temporary power circuits in and around the work area, it is especially important to have a detailed plan…and most important…to communicate it effectively with all those involved.

POINT 5: ANTICIPATING UNEXPECTED EVENTS

The facility did not expect a large rodent to walk across the 15 kV PT compartment and blow it up. This was an unexpected event and was not planned for.

But the work you are doing to remediate the issues should be planned and should include considerations built-in for unexpected events. A few examples of unexpected event planning:

- What is the expected time frame for the repair…and what if you don’t finish it on time

- Are the workers putting in excessive hours?

- Are production personnel coming in to start the facility back up?

- If you are running on temporary power, do you have a fuel contingency?

- You open up the switchgear and find additional problems. Do you have an after-hours source for parts and equipment?

- What about the upstream devices – did you damage something else?

- Is there a re-energization plan when the repairs are completed?

When performing repairs after a significant fault event, it is wise to under-promise and over-deliver. Be conservative in the timing of your repair estimates and clear-headed in your promises. This makes for a safer recovery, puts less pressure on the workers in the field, and leads to a more effective execution of the tasks in front of you. Anticipate all the “gotchas” before they get you. Take your time and think it through. After all, it’s electrical equipment!

POINT 6: ENSURING THE QUALIFICATIONS AND ABILITIES OF WORKERS

This is electrical work. It is dangerous, and it can kill you.

Please, make sure you and your people have the necessary knowledge, skills, and abilities for any of the tasks they are expected to perform.

Recognize the Unqualified

Key Point — Article 100, Definition of Qualified Person

NFPA 70E is very clear on the definition of a qualified person, which states:

One who has demonstrated skills and knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify the hazards and reduce associated risk.

The personnel performing the task, whatever it might be, must be qualified for the task they are expected to perform. It’s important to note that being a degreed engineer, a certified technician, or a licensed electrician does not automatically make you qualified for the task in front of you.

A qualified employee must understand the construction and operation of the equipment or the circuit that is associated with the required task. Do you understand 15 kV potential transformer (PT) and current transformer (CT) circuits? Do you understand the construction and operation of medium-voltage circuit breaker cell interlocks and insulation systems? What about line-to-ground clearances and allowable cable bending radii? These are all decision-making elements of our feeder M1A repair, and the worker must have the skills and knowledge to navigate these points.

If your people are qualified, and they understand the hazards, risks, construction, operation, nominal voltages, normal operation requirements, and how to properly interact with the equipment…the likelihood of having a safe, successful repair and restoration of power is greatly increased.

Quality Worker

Stayed tuned for the next issue of NETA World as we determine the equipment’s condition of maintenance and use tools and portable meters to bring the facility back online and bring this unexpected electrical fault event to a close.

And finally, always turn it off before working on it!

Ron Widup is the Vice Chairman, Board of Directors, and Senior Advisor, Technical Services for Shermco Industries and has been with Shermco since 1983. He is a member of the NETA Board of Directors and Standards Review Council; a member of the Technical Committee on NFPA Standard for Electrical Safety in the Workplace (NFPA 70E); Principal member of the National Electrical Code (NFPA 70) Code Panel 11; Principal member and Chairman of the Technical Committee on Standard for Competency of Third-Party Evaluation Bodies (NFPA 790); Principal member and Chairman of the Technical Committee on Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation (NFPA 791); a member of the Technical Committee Recommended Practice for Electrical Equipment Maintenance (NFPA 70B); and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. He is a member of the Texas State Technical College System (TSTC) Board of Regents, a NETA Certified Level 4 Senior Test Technician, State of Texas Journeyman Electrician, a member of the IEEE Standards Association, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).

Ron Widup is the Vice Chairman, Board of Directors, and Senior Advisor, Technical Services for Shermco Industries and has been with Shermco since 1983. He is a member of the NETA Board of Directors and Standards Review Council; a member of the Technical Committee on NFPA Standard for Electrical Safety in the Workplace (NFPA 70E); Principal member of the National Electrical Code (NFPA 70) Code Panel 11; Principal member and Chairman of the Technical Committee on Standard for Competency of Third-Party Evaluation Bodies (NFPA 790); Principal member and Chairman of the Technical Committee on Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation (NFPA 791); a member of the Technical Committee Recommended Practice for Electrical Equipment Maintenance (NFPA 70B); and Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. He is a member of the Texas State Technical College System (TSTC) Board of Regents, a NETA Certified Level 4 Senior Test Technician, State of Texas Journeyman Electrician, a member of the IEEE Standards Association, an Inspector Member of the International Association of Electrical Inspectors, and an NFPA Certified Electrical Safety Compliance Professional (CESCP).