America has been built on progress. Author C.S. Lewis once stated:

“We all want progress, but if you’re on the wrong road, progress means doing an about-turn and walking back to the right road; in that case, the man who turns back soonest is the most progressive.”

It could certainly be contended that the man who never has to turn back is truly the most progressive. That considered, the road travelled to build America’s electric vehicle (EV) charging infrastructure must be the right one — comprised of safe installation, use, and maintenance. With the task at hand and the investment being made, there is no time to turn back.

President Biden has been clear about his plans to develop America’s nationwide EV charging infrastructure and providing the funding to do so. The Biden administration, including the USDOT and USDOE, announced plans in early 2022 to provide $5 billion over five years to build a nationwide EV charging network as part of the Infrastructure Investment and Jobs Act (IIJA). The funds will be made available under the newly formed National Electric Vehicle Infrastructure (NEVI) Formula Program. The investment in the fiscal year of 2022 alone is projected to be roughly $625 million.

As a part of the IIJA, President Biden also announced a focus on zero-emissions vehicles. In response, the American automotive industry has set a lofty goal for their total vehicle sales to be made up of roughly 50% EVs by 2030, with continued growth thereafter. Some individual companies have set even more aggressive targets for converting their production to EVs. Buick, the oldest active American car brand at 119 years old, announced that they plan to fully convert to an electric-only automaker by the end of this decade.

In further support of converting America to zero-emissions vehicles, it was announced in early May that IIJA would provide an additional $3.1 billion to assist in making more batteries and components on American soil, also expected to “bolster domestic supply chains, create good-paying jobs, and lower costs for families.”

As the nation begins its shift from the long-standing norm of combustion-engine vehicles over to electric vehicles, it is critical that everyone has a place to charge where and when needed. Do you remember a time where there wasn’t a gas station on nearly every street corner in America? I don’t either, but having an EV charging station within close proximity to all Americans will be paramount for a successful transition to EVs. Access will not only be necessary within cities, but also in rural areas. Many Americans have already begun installing EV power transfer systems within their homes. Some areas of the country are even beginning to require new homes to be built with EV power transfer systems installed or provisions being made for them to be installed once a new owner takes occupancy of the home. This is sometimes referred to as EV-ready.

This undertaking of creating a nationwide EV charging infrastructure is not on the administration alone; it’s also on the shoulders of every American. Manufacturers, installers, and consumers will have critical roles in the ongoing development of the EV infrastructure and its overall functionality and sustainability. To continue down the right road — one that does not call for turning back — we must all do our part to ensure that the successful development of America’s EV charging infrastructure is achieved.

SAFELY INSTALLED

Likely the heaviest lift for creating the EV charging infrastructure will be the actual installation of the power transfer systems themselves. Ensuring that the installation is done properly, meeting both manufacturer and code requirements, is a great start to ensuring overall safety. Currently, EV power transfer systems include electric vehicle supply equipment (EVSE), wireless power transfer equipment (WPTE), and electric vehicle power export equipment (EVPE).

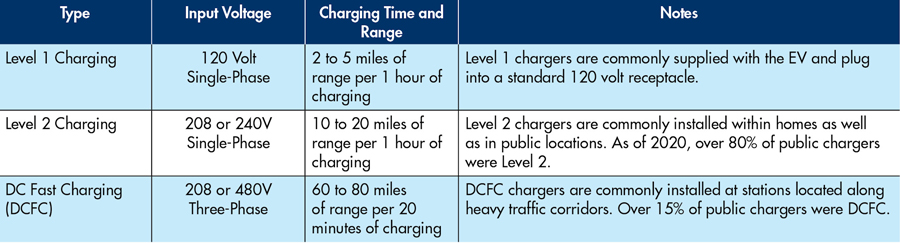

EVSE can be broken down into three categories (Table 1): Level 1, Level 2, and DC Fast Charging (DCFC).

Table 1: Categories of electric vehicle supply equipment (EVSE)

- Level 1 EVSE are typically portable-style chargers provided with the EV from the auto manufacturer. They are by far the slowest of the EVSE options, but are most convenient based upon their ability to plug into any standard 120-volt outlet.

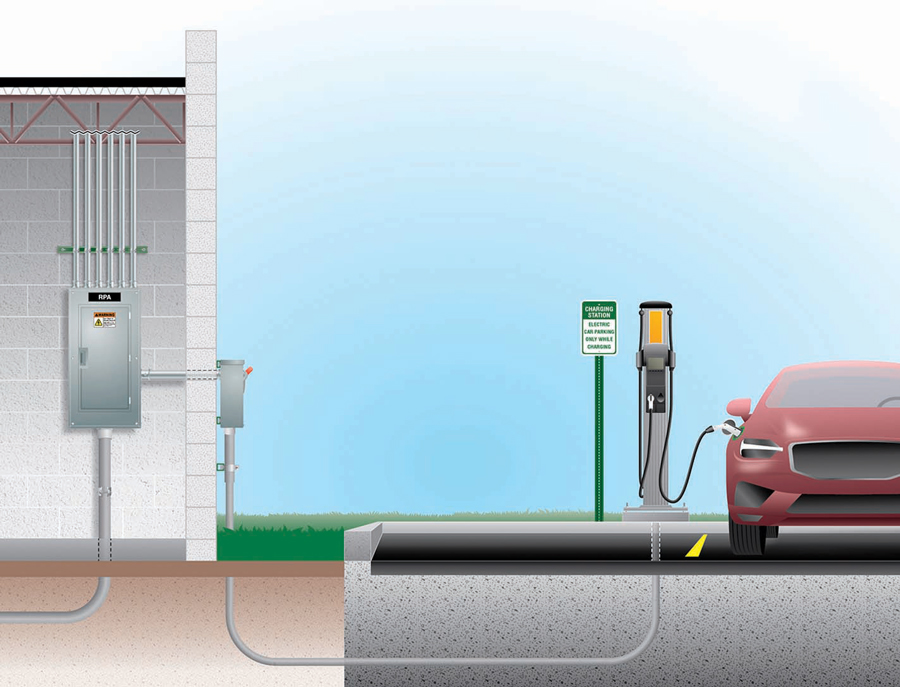

- Level 2 EVSE are more commonly installed in homes and businesses. Typically operating at 208 volt or 240 volt, single-phase, Level 2 EVSE (Figure 1) can be plugged in at the end of the day and provide a full, or nearly full, charge by morning.

- DC Fast Chargers (DCFC), at times referred to as Level 3, are the closest product on the market right now to compare to a fuel dispenser when it comes to the time it takes to charge the vehicle. DCFC typically require a high-capacity three-phase power source and therefore are most practical at locations other than dwelling parking facilities and along interstate highway corridors.

Figure 1: EVSE Installation

Load

A key initial consideration for installing EVSE is the additional load it will impose on the existing electrical service. In some cases, the existing electrical service may be undersized to supply the load demands of the EVSE. For example, depending on the service size, a home that utilizes larger appliances and equipment that operate at 240 volts, such as an electric range, electric dryer, and air conditioning condenser, may not have the additional capacity and space necessary to add a Level 2 EVSE requiring 30–50 amps at 240 volts.

While installing the EVSE on an undersized electrical service may initially work, it would jeopardize safety by putting the overall home electrical system at risk of overload. Within any home or building, to ensure an electrical service has adequate capacity and space to add an EVSE, a thorough service load calculation should be performed by a qualified individual. An EVSE with adjustable settings can be installed and can be set to a rating that matches the branch circuit rating or limited service capacity available on an existing wiring system.

Additionally, EVSE can be connected to an energy management system (EMS) controllable through an internet connection or interactive with a utility demand/response system that limits the supply to the EVSE when the capacity is not available while connected to an EV.

NEC Requirements

The National Electrical Code® (NEC®) should be the foundation for all safe EVSE installations. The very purpose behind the NEC states that the intent of the code is the practical safeguarding of persons and property from hazards arising from the use of electricity. Based on the 2020 NEC, Article 625 Electric Vehicle Power Transfer System covers the electrical conductors and equipment connecting an electric vehicle to premises wiring for the purposes of charging, power export, or bidirectional current flow. The scope statement listed in 625.1 was modified during the 2020 NEC cycle to include power export and bidirectional current flow as EVs continue to evolve to not only consume power, but also have the ability to redistribute available onboard power from the EV to the premise’s wiring system or even to the serving utility.

Another significant modification made during the 2020 NEC cycle around power export and bidirectional current flow was in Section 90.2, which covers the overall scope of the NEC. In 90.2(A), which specifies which installations the NEC does cover as opposed to 90.2(B) which states what the NEC does not cover, a section was added to state that the NEC covers

…installations used to export electric power from vehicles to premises wiring or for bidirectional current flow.

This change was significant for EV installations that utilize these methods as being overseen by NEC requirements and is also unique in that the overall scope of the NEC is rarely changed. Therefore, doing so makes the need for NEC governance in setting forth requirements for safe EV installations apparent.

A similar area of Article 625 that helps ensure safe installations is Section 625.5, which requires all equipment to be listed. Section 625.5 is further supported by Section 110.3, which requires all equipment installed based on the NEC to not only be listed or labeled by a qualified electrical testing laboratory (QETL), but also to be installed based on any instructions included in the listing or labeling. Ensuring the equipment is listed confirms that the EVSE has been tested by a qualified laboratory. This will help prevent the utilization of any unlisted equipment found in the counterfeit market that could be unsafe for installations.

While the NEC as a whole is written toward safe electrical installations, several other key areas are specific to ensuring safe EV installations:

- 625.17(C) Overall Cord and Cable Length. The maximum overall length of the EVSE cord cannot exceed 25 feet unless the EVSE is equipped with a cable management system. Cords are arguably the most-used portion of the EVSE and are therefore subject to the most wear. Ensuring the cord length is adequate to reach where necessary, but not longer than 25 feet, provides less opportunity for wear and potential fraying or punctures to the cord, helping to ensure safety to users handling the cord.

- 625.22 Personnel Protection System. The NEC requires all EV equipment to have a listed system of protection against shock for individuals using the equipment. This system may consist of one or more components that provide protection against electric shock for different portions of the EVSE circuitry. Typically, personal protection systems are incorporated into EVSEs by manufacturers designing the internal circuitry to meet UL 2231-1 and UL 2232-2 standards.

- 625.40 Electric Vehicle Branch Circuit. Any outlet that supplies EVSE is required to be installed on an individual branch circuit, and that circuit is not permitted to contain any other outlets. By NEC definition, an “individual branch circuit” is one that supplies only one utilization equipment. Requiring a circuit dedicated just to the EVSE helps to avoid the overloading that could occur if other loads were on the same circuit. This keeps the EVSE functional and the branch circuit wiring safe.

- 625.54 Ground-Fault Circuit-Interrupter Protection for Personnel. While some EVSE have a direct-wired connection, the majority are cord-and-plug connected. The NEC requires all receptacles installed for cord-and-plug-connected EVSE to have ground-fault circuit-interrupter (GFCI) protection. In addition, the manufacturer’s instructions may call for GFCI protection to be installed for branch circuits that feed direct-wired EVSE. Because EVSE is often installed and utilized in areas subject to moisture, installing GFCI protection will reduce the risk of shock to users.

EV installations that are NEC compliant have safety at their core. Every three years, the NEC undergoes a new cycle of the NFPA standards development process, which provides an opportunity for changes to be submitted that incorporate advancements within the electrical industry. With constantly changing technology such as that which is involved with EVs, it is important to utilize the most current version of the NEC to ensure the safest installation possible.

SAFELY USED

While code requirements can define what must be incorporated into an installation to keep people safe, the actions of the individuals utilizing EVSE also weighs heavily on safety. Manufacturer’s instructions are a great starting point for proper usage of EVSE. These instructions are specific to the particular equipment and will tell users what to do, and also what not to do, to ensure safety during use and optimal performance of the EVSE. Initially, it is also important that EVSE are installed only by a qualified electrician who performs the installation based on NEC requirements.

Home EVSE Installation

Additional tips that can help end users safely charge their EVs include:

- Follow manufacturers’ guidelines when connecting your vehicle to EVSE. It is not only important to utilize the EVSE manufacturer’s instructions, but also to adhere to instructions from the automotive manufacturer of the EV.

- Visually check EVSE components before using. Look for physical damage to equipment, such as wear or damage to the charging cord, connectors, or plugs. Special attention should be paid to public charging stations where there is a high level of usage by multiple handlers, as excessive wear may take place faster than with private EVSE at a home or business. Never use an EVSE cord that appears to be damaged in any way or is showing exposed conductors.

- Do not use extension cords or cord adapters. Never utilize an extension cord or cord adapter when supplying an EVSE. Not only is it unsafe to use extension cords or cord adapters with EVSE, but it may also impact the performance of the power transfer system. Only use an EVSE with the cords and components that it comes with out of the box from the manufacturer.

Plenty of safe charging information can be found online for EVs. Organizations such as the Electrical Safety Foundation International (ESFi) provide helpful safety tips for EVSE end users. It’s extremely important for users to understand what they must do when charging their EV to ensure their own safety and to continually follow that process.

SAFELY MAINTAINED

With the effort and financing it will take to build America’s EV charging infrastructure, it is crucial that it remain sustainable by being maintained properly after installation. The manufacturer’s instructions will play a key role in helping to determine maintenance needs on the specific EVSE that is utilized throughout the infrastructure.

Another information source for performing maintenance for electric vehicle power transfer is NFPA 70B®, Recommended Practice for Electrical Equipment Maintenance®. Chapter 34 is dedicated specifically to electric vehicle charging systems. An initial recommendation in the chapter introduction is that a maintenance plan should be created at the time the electric vehicle charging system is initially installed. This will help ensure the greatest level of safety to workers who will maintain the system as well as the highest level of reliability and safety for the user of the EVSE.

Only qualified persons should perform maintenance on an EVSE. Cords, connectors, and equipment as a whole should be inspected for damage on a regular basis. In some cases, damage can occur during severe weather, so all equipment should be inspected after any significant environmental event. Due to the nature of EVSE, there is an innate susceptibility to vehicular impacts to the equipment. The integrity of the ESVE mounting should be regularly inspected and maintained to ensure it remains intact. Regular maintenance of the EVSE and its components will help keep potential repair costs down, as well as help ensure that systems remain reliable and functional for all users.

DRIVING FORWARD

Our world is changing all around us as America begins to make the transition to utilizing EVs. Look around you, because what you see today is not likely to be what you see tomorrow as the EV infrastructure starts taking shape and EV charging stations start popping up like dandelions in the springtime. The forward path EVs are taking has already begun to introduce new technologies such as power export, bidirectional current flow, and wireless power transfer — all of which have been acknowledged and incorporated into the NEC to ensure safe electrical installations of those systems.

Installation of a road that automatically charges EVs has already begun in Detroit, and safe installation requirements will likely need to be addressed. Other means of electric transportation, such as boats, are being developed where specific requirements may be needed for power transfer that is done on water instead of land. The EV charging infrastructure that is being implemented right now is clearly based on automobiles, but who knows where it will lead us to eventually. Regardless of what ends up being charged as part of the infrastructure years from now, we know the foundation needs to be built on safe installation, use, and maintenance. We know what we must do, and it’s time to get to work, America.

Information: For free individual training around EVs and help determining whether or not your community is ready to implement EVs, please visit the National Fire Protection Association (NFPA) and Clean Cities Coalition Electric Vehicle Community Preparedness website at www.ReadyforEVs.com.

Important Notice: Any opinion expressed in this column is the personal opinion of the author and does not necessarily represent the official position of NFPA or its Technical Committees. In addition, this piece is neither intended, nor should it be relied upon, to provide professional consultation or services.

Corey Hannahs is a Senior Electrical Content Specialist at the National Fire Protection Association (NFPA). In his current role, he serves as an electrical subject matter expert in the development of products and services that support NFPA documents and stakeholders. Corey is a third-generation electrician, holding licenses as a master electrician, contractor, inspector, and plan reviewer in the state of Michigan. Having previously held roles as an installer, owner, and executive, he has also provided electrical apprenticeship instruction for over 15 years. Corey was twice appointed to the State of Michigan’s Electrical Administrative Board by former Governor Rick Snyder, and he received United States Special Congressional Recognition for founding the B.O.P. (Building Opportunities for People) Program, which teaches construction skills to homeless and underprivileged individuals.

Corey Hannahs is a Senior Electrical Content Specialist at the National Fire Protection Association (NFPA). In his current role, he serves as an electrical subject matter expert in the development of products and services that support NFPA documents and stakeholders. Corey is a third-generation electrician, holding licenses as a master electrician, contractor, inspector, and plan reviewer in the state of Michigan. Having previously held roles as an installer, owner, and executive, he has also provided electrical apprenticeship instruction for over 15 years. Corey was twice appointed to the State of Michigan’s Electrical Administrative Board by former Governor Rick Snyder, and he received United States Special Congressional Recognition for founding the B.O.P. (Building Opportunities for People) Program, which teaches construction skills to homeless and underprivileged individuals.