Transformers are subjected to electrical, thermal, and chemical stresses during their operational life that degrade the insulating oil and solid insulation, cause corrosion and oxidation, and create the conditions for incipient faults to develop, which may ultimately shorten the life of the asset. These ageing processes are necessarily considered during the transformer design phase.

However, degradation that occurs faster than anticipated is considered to be accelerated ageing. For instance, a high-resistance joint causing localized overheating or partial discharge degrading the solid insulation are examples of premature ageing.

Although simple visual inspection of the transformer tank to look for corrosion or leaks or IR surveys to identify overheating pumps yields important condition information, not all issues will be visible from the outside. Fortunately, incipient faults occurring within the transformer can be identified and diagnosed by examining the chemical, physical, and electrical properties of the liquid dielectric within it. This is usually performed at an external laboratory; however, some larger utilities or industrial entities may undertake in-house testing.

This article:

- Looks at the importance of sending high-quality oil samples to the laboratory to be tested

- Considers the types of problems that can be identified by dissolved gas-in-oil analysis (DGA) and what next steps may be taken

- Considers some of the other oil tests that are conducted and the important information that can be revealed

COMMON TESTS AND BEST PRACTICES TO IMPLEMENT NOW

An oil sample can reveal a wide variety of information about the condition of your asset; this includes evidence of overheating, partial discharge and arcing, paper degradation, water ingress, oxidation, presence of chemical and physical contaminants, and more. Consequently, oil testing is a key method for assessing a transformer’s condition and identifying incipient faults before they become critical. A single measurement is valuable, but trending changes in the data over time enhances the diagnosis by revealing the severity of the situation and enables asset managers to plan appropriate actions. This could involve off-line electrical tests to determine the underlying cause, fitting on-line monitoring devices to monitor the condition of the asset more effectively, or scheduling a repair or replacement.

Importance of a High-Quality Sample

Ensuring good results for your assessment starts with delivering a good oil sample to the lab. Even perfectly performed lab tests are rendered meaningless if they are based on a poor sample. Failing to take the sample correctly will inevitably lead to poor results and the additional cost of having to retake the sample and perform the analysis yet again. A good sample needs to be truly representative of the bulk liquid circulating within your electrical equipment. Getting to this representative oil requires several liters of oil to be flushed through the sampling pipework and into an appropriate waste oil container prior to collecting the sample proper. In the process of waiting for the flushing to complete, this oil can be used to rinse the sample container and caps to ensure they are free from physical contamination.

Oil Bottles

When taking a sample, it is beneficial that your container is large enough to hold the amount of oil needed with some extra just in case the lab needs to repeat a test to verify unusual results; this typically means about 1 liter. There are many suitable containers for taking an oil sample and each has its own benefits and pitfalls. Generally, glass or aluminum bottles or tin cans are the preferred options. The container should properly seal the sample, preventing ingress and egress of any liquids and gasses. Since oil degrades in sunlight leading to the synthesis of hydrogen, the containers, sleeves, and/or packaging should be light proof to protect the sample from sunlight.

Plastic bottles should be avoided since water molecules can diffuse through the container walls, thus increasing the water content of the sample. Studies have revealed that 10s of parts per million (ppm) of water can enter the sample during transportation and storage before testing. Conversely, small molecules like hydrogen can diffuse out of the oil through the plastic container walls, which decreases the concentration ultimately measured in the sample.

Lastly, it’s important to pack the samples well to avoid damage during transportation to the oil testing laboratory. Make sure the bottoms of the bottles are protected as well.

DISSOLVED GAS ANALYSIS (DGA) CARRIES THE MOST WEIGHT

DGA is arguably the most powerful tool in the industry when it comes to assessing transformer condition. Commonly performed according to ASTM D3612C and known as the headspace method (also detailed in IEC 60567), this diagnostic test measures the concentration of certain key gases dissolved in the oil. Additionally, provided oil samples are taken at regular intervals, the rate of gas generation can also be determined. This information enables specialists to understand which faults are emerging and their severity.

While acetylene is the most important gas to measure for detecting severe faults, all gases are important from an incipient fault perspective. The types and quantities of gases that form within the insulating oil will unveil the nature of the fault and determine whether it involves the solid insulation, is a thermal or electrical issue, and whether there is a leak within the sealed system or premature degradation in an open system.

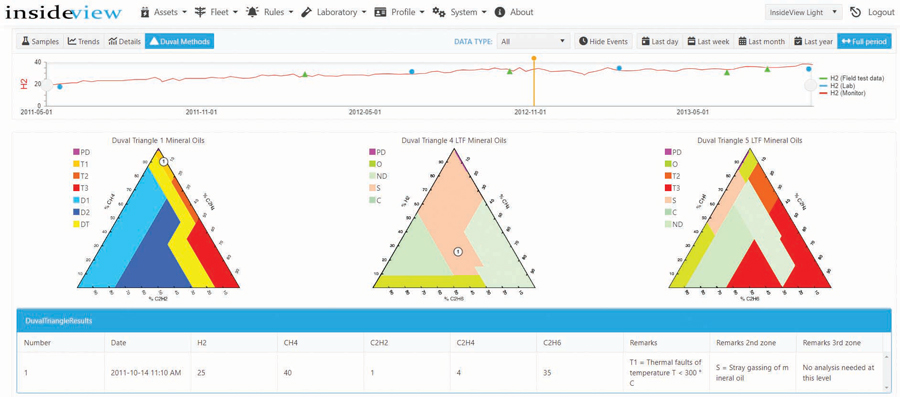

There are many recognized methods for interpreting DGA data — with insufficient time to review here — as well as suggested gas limits in guides such as IEEE C57.104-2019 and IEC 60599. Nevertheless, it’s important to remember that allowance must be made for factors such as the type of the dielectric oil involved (silicone, mineral, or ester fluids). However, a high-level summary of DGA interpretation (Figure 1) would include:

- Acetylene usually indicates arcing or a high-temperature thermal condition.

- To check for partial discharge, look at hydrogen levels.

- For low-temperature faults, pay close attention to ethane and methane.

- Ethylene is an indicator of a high-temperature thermal issue.

- In temperate climates, high levels of carbon monoxide are a sign of paper degradation, whereas in hotter climates, high levels of CO can persist without other indicators of paper degradation being present.

- High levels of carbon dioxide can indicate general overheating of the paper insulation.

Figure 1: Duval Triangle from insideview

A single set of DGA data fails to inform us whether the gas concentrations are stable, increasing, or even subsiding, or indeed how long they have been there, or if they are associated with a known incident like a transient condition, or if they occur when the transformer is stressed in a particular manner. All that is known is that gases are present and the concentration of each. This may indicate an issue, but it cannot indicate whether there is an active problem. Therefore, a trend of several data points needs to be established. This will inform the asset manager if the gassing is stable, becoming more intense, or is progressing from one fault type to another.

Even after having established the DGA trend, as with all diagnostic tests, context is paramount. Know the normal behavior for your asset, its age, and local conditions, such as ambient temperature, loading, transients, harmonics, or other circumstances that would explain the gases in the oil. Comparing gassing of an asset to sister units (if available) can provide additional information. Changes in the gassing levels may have been caused by a change in loading pattern or a through fault. Also consider any maintenance activities that have been performed. Have any repairs been made? What electrical tests have been conducted? If results from several transformers have changed, has there been a change in sampling procedure or the laboratory used?

Under some circumstances degassing of the transformer oil is undertaken — typically, when filling a new transformer or after maintenance that has exposed the core and windings. This inevitably changes DGA values and requires new benchmark tests to reestablish the trend in gas behavior over a period of time (at least 3 months). It’s important to remember that degassing the oil will not fix the underlying cause of the problem; it erases the DGA trend and, as a procedure, is not risk free even when using competent contractors.

OIL QUALITY DATA

The diagnostic value of monitoring changes in the chemical, physical, and dielectric properties of the oil cannot be understated, as these can also degrade over time and affect the performance of the transformer. Here, we consider some of the other tests that provide further valuable information about oil quality.

Checking for Oil Quality: Water Content, Relative Saturation and Breakdown Voltage

Water is the most damaging molecule in the transformer. When dissolved in the oil, it catalyzes reactions, weakens bonds, attracts other polar contamination to the paper, and allows acids to be aggressive. Conversely, free water in oil will generally sink to the bottom of the transformer where it contributes to tank corrosion. If it precipitates onto a winding due to oversaturation, it can cause flashovers.

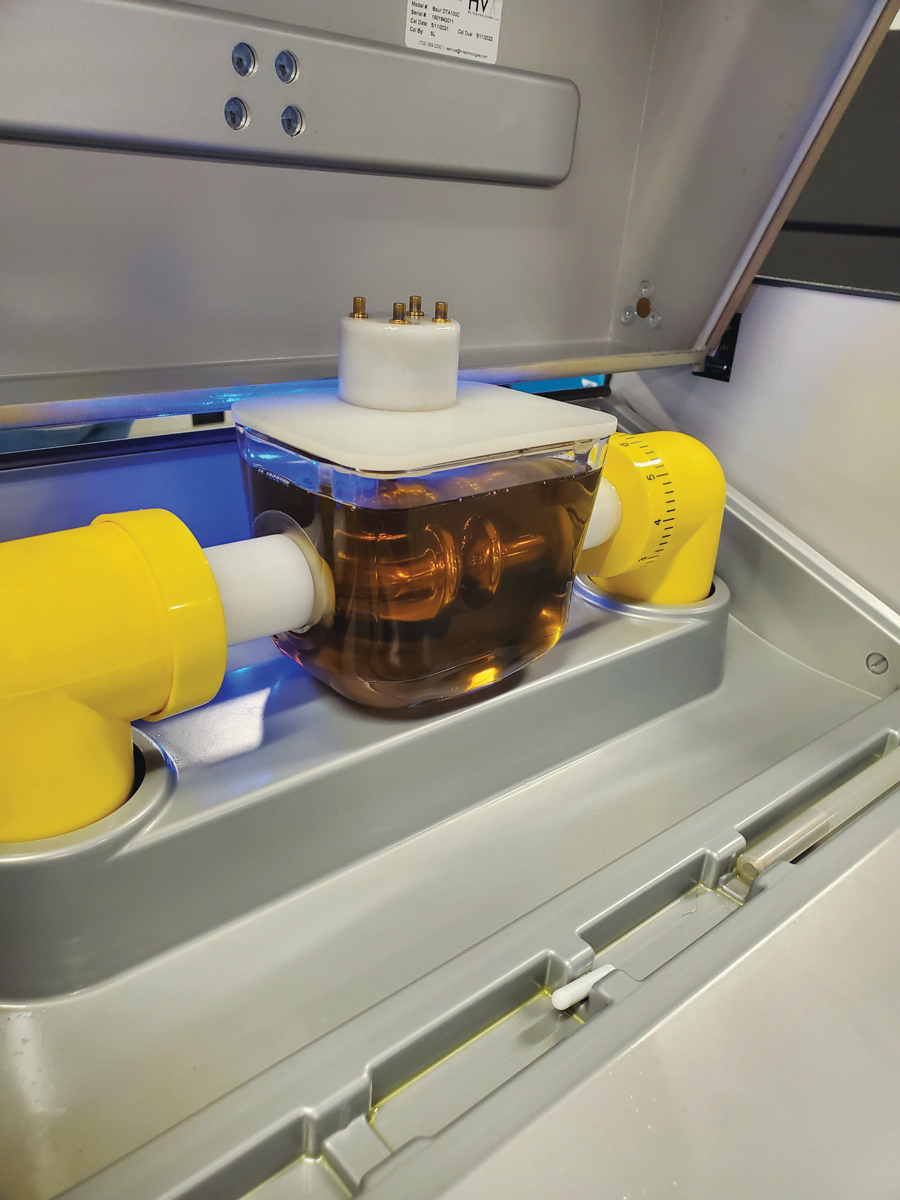

Photo 2a: Breakdown Voltage Cell

Photo 2b: Breakdown Voltage Cell

Water concentrations are generally much lower in the oil compared to the paper. Typically, water exists at parts-per-million (ppm) levels in the oil compared to single-figure percentage levels in the paper. This is because paper itself has polar components (e.g., hydrogen bonding), which although giving the paper additional mechanical strength, also attract water molecules. The presence of water in the paper is important as it disrupts the hydrogen bonds reducing the physical strength of the paper.

Knowing how water partitions between the oil and paper means that by measuring the water content in the oil, the content in the paper can be calculated. Nevertheless, different oils have different levels of affinity for water. Thus, it is important to know which oil is being tested as the difference is particularly marked between mineral oils and ester liquids. To further complicate the situation, the polarity of the oil can be affected by ageing byproducts. It is therefore better to examine the relative saturation of water in oil rather than ppm. It should remain below 50% to retain adequate dielectric breakdown voltage.

Under particular circumstances, the water in the paper can generate gas bubbles, for example, during transformer overloading events or during startup before adequate oil circulation is established. Under these conditions, the conductors can heat the paper above 100˚C causing water to vaporize, thereby increasing the likelihood of bubble formation, which in turn can lead to partial discharge (PD) and risks localized physical PD damage. The probability of bubble formation is dependent on both the concentration of the water in the paper and temperature; for example, with 2% by dry weight of water in the paper, the risk of bubble formation is very low below 140°C.

Transformer oils are designed to provide electrical insulation under high-electrical fields. Any significant reduction in the dielectric strength may indicate that the oil is no longer capable of performing this vital function. Breakdown voltage (BDV) is a measure of the electrical stress the oil can withstand without breaking down. The test is conducted by increasing the voltage between two electrodes within a test vessel containing the test oil until the oil breaks down. Sampling technique plays a significant role in obtaining meaningful breakdown voltage results, Particles and fibers accidentally introduced during cleaning the test cell or sampling bottles (chamois leather, cotton rags, paper towels) can all drastically reduce the measured result.

Accelerated Aging: Power Factor, Color Testing, and Interfacial Tension Identify Key Characteristics

Transformers typically last at least 40 years even though the design life is usually around 25 years — but that is not by accident. Keeping the asset sealed and operating at or below nameplate will preserve this life expectancy. High temperatures, elevated levels of oxygen, water content, acidity, and sludging — all in the presence of other catalytic factors like copper in the windings, silver contacts, and iron — can speed up the aging of paper and insulating oil, as well as corrode the metal in the transformer.

Three recommended tests identify oil aging or contamination, thus enabling early intervention:

1. Power factor testing measures the dielectric losses of the insulating oil. As the oil oxidizes with increasing time in service, the polar content increases, which can be detected through increased power factor. This test can also detect the presence of other contamination in the oil, and while it cannot identify the actual molecules, it highlights the need for further investigation.

2. Color tests are a simple rapid indicator of aging in the insulation system; the darker the oil sample, the more aged the oil.

3. Interfacial tension (IFT) is an indirect measure of the polar nature of the oil and provides powerful insight into early oil oxidation and polar contaminants, such as water or acids. The test measures the strength of the separation between water and the oil sample. Oil and water should form distinct layers when there is little contamination in the oil, but as the oil becomes aged or wet, the tension between the liquids becomes less distinct and therefore weaker, such that a lower IFT result is worse than a higher one. It should be noted that IFT is also affected by the presence of detergents such that residual deposits from cleaning sampling equipment, sampling containers, or the test vessel with such surfactants can have a dramatic effect on this test parameter.

Other oil quality tests such as acidity and relative density can be performed in tandem for a more in-depth examination of the characteristics of the oil. It takes gross contamination, aging, or over-processing for these properties to change significantly, so if either of these values fluctuates between tests, it could be cause for concern. If an issue with the oil does present itself, there are other investigative tests that can be employed.

SUMMARY

Analysis of oil samples collected from transformers is the starting point for understanding the condition of the asset. The applied tests can reveal a lot about incipient faults or developing problems. Nevertheless, additional contextual information and further electrical testing may be required to build a complete picture of the underlying problem and diagnose the root cause.

Simon Sutton is Director of Services for Altanova, a Doble company, where his responsibilities include business strategy, external relationships, and coordination of technical activities around the world. He has over 25 years of experience in the electricity transmission and distribution industry predominantly in the cables sector. He has worked in the cable materials supply industry, as the cables policy manager for a transmission utility, and in the research sector. His interests also include condition monitoring, diagnostic testing, forensics, and asset management. Simon earned a PhD in physics from the University of Reading. He is active in International professional bodies representing UK on the CIGRE Study Committee for Materials and Emerging Test Techniques, is Convenor of the CIGRE Strategic Advisory Group on Solids, and is a member of the editorial board of the IEEE Electrical Insulation Magazine. He is a Visiting Senior Research Fellow at the University of Southampton.

Simon Sutton is Director of Services for Altanova, a Doble company, where his responsibilities include business strategy, external relationships, and coordination of technical activities around the world. He has over 25 years of experience in the electricity transmission and distribution industry predominantly in the cables sector. He has worked in the cable materials supply industry, as the cables policy manager for a transmission utility, and in the research sector. His interests also include condition monitoring, diagnostic testing, forensics, and asset management. Simon earned a PhD in physics from the University of Reading. He is active in International professional bodies representing UK on the CIGRE Study Committee for Materials and Emerging Test Techniques, is Convenor of the CIGRE Strategic Advisory Group on Solids, and is a member of the editorial board of the IEEE Electrical Insulation Magazine. He is a Visiting Senior Research Fellow at the University of Southampton.

Lance R. Lewand is the Technical Director for the Doble Insulating Materials Laboratory. The Insulating Materials Laboratory is responsible for routine and investigative analyses of liquid and solid dielectrics for electric apparatus. Since joining Doble in 1992, Lance has published over 75 technical papers pertaining to testing and sampling of electrical insulating materials and laboratory diagnostics. He is actively involved in professional organizations including the American Chemical Society and has been a representative of the U.S. National Committee for TC10 of the International Electrotechnical Commission (IEC) and ISO TC28, ASTM D-27 since 1989. Lance is Chair of ASTM Committee D-27, chairs subcommittee 06 on Chemical Tests, is secretary of the Doble Committee on Insulating Materials, and received the ASTM Award of Merit for Committee D-27. He received his BS from St. Mary’s College of Maryland.

Lance R. Lewand is the Technical Director for the Doble Insulating Materials Laboratory. The Insulating Materials Laboratory is responsible for routine and investigative analyses of liquid and solid dielectrics for electric apparatus. Since joining Doble in 1992, Lance has published over 75 technical papers pertaining to testing and sampling of electrical insulating materials and laboratory diagnostics. He is actively involved in professional organizations including the American Chemical Society and has been a representative of the U.S. National Committee for TC10 of the International Electrotechnical Commission (IEC) and ISO TC28, ASTM D-27 since 1989. Lance is Chair of ASTM Committee D-27, chairs subcommittee 06 on Chemical Tests, is secretary of the Doble Committee on Insulating Materials, and received the ASTM Award of Merit for Committee D-27. He received his BS from St. Mary’s College of Maryland.

Andy Davies has worked for Doble for more than six years. His work commenced with 2.5 years in the Middle East providing asset health indexing and maintenance guidance for over 2,400 transformers for a middle eastern transmission company. Since then, he has been involved with support and training for online asset management tools, hardware support for portable and field oil testing equipment, and provides transformer consultation for customers located across EMEA. Prior to Doble, he worked with an oil services company that provided oil reclamation and mobile oil solutions that included technical consultation for all generators, HV contractors, transmission, and distribution utilities across the UK and Ireland. He has led research into DBDS and acidity in transformers and their mitigation strategies and has a sound understanding of oil chemistry.

Andy Davies has worked for Doble for more than six years. His work commenced with 2.5 years in the Middle East providing asset health indexing and maintenance guidance for over 2,400 transformers for a middle eastern transmission company. Since then, he has been involved with support and training for online asset management tools, hardware support for portable and field oil testing equipment, and provides transformer consultation for customers located across EMEA. Prior to Doble, he worked with an oil services company that provided oil reclamation and mobile oil solutions that included technical consultation for all generators, HV contractors, transmission, and distribution utilities across the UK and Ireland. He has led research into DBDS and acidity in transformers and their mitigation strategies and has a sound understanding of oil chemistry.