Everyone wears clothes, at least when out in public. However, not everyone needs to wear clothes specially designed and tested to protect them from hazards they could find in their workplace. If your employees work on or near electric power, generation, transmission, and distribution equipment, specialized clothing is necessary for certain tasks.

OSHA 29 CFR 1910.269 states that employers must assess a workplace to determine whether an employee will be exposed to the hazards of flames or electric arc. If there is a potential for exposure, the employer must estimate the amount of potential incident energy in heat the employee could be exposed to and must provide the appropriate personal protective equipment (PPE).

If the employee will be exposed to flames and arcs, the employer must first ensure that clothing material is not untreated, meltable fabric (i.e., polyester, rayon, fleece, etc.). The available types of materials can all be found in ASTM F1506, Flame Resistant and Arc Rated Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards.

Second, to paraphrase OSHA: The employer shall ensure that the outer layer of clothing worn by an employee, except for clothing not required to be arc rated, is flame resistant under any of the following conditions:

- The employee is exposed to contact with energized circuit parts operating at more than 600 volts.

- An electric arc could ignite flammable material in the work area that could, in turn, ignite the employee’s clothing.

- Molten metal or electric arcs from faulted conductors in the work area could ignite the employee’s clothing.

- The incident heat energy exceeds 2.0 cal/cm2.

NFPA 70E, Standard for Electrical Safety in the Workplace states that the employer must provide arc rated clothing for potential arc flash hazards in any area that is not regulated by OSHA 1910.269. This includes commercial, industrial, and residential construction workplaces. NFPA 70E Section 130.4 and Section 130.6 clearly state it is the employer’s responsibility to identify the hazards and provide the necessary arc rated clothing to mitigate those hazards. It also instructs the employee in proper inspection of that PPE.

Washing Instructions, Ratings, and Certification of Arc Rated Clothing

Once it is determined that arc rated, flame resistant clothing is required, the employer must provide clothing that is appropriately rated for the potential hazard. To paraphrase OSHA: The employer shall ensure that each employee exposed to hazards from electric arcs wears protective clothing and other protective equipment with an arc rating greater than or equal to the estimated heat energy whenever that estimate exceeds 2.0 cal/cm2. This protective equipment shall cover the employee’s entire body, except as follows:

- Arc rated protection is not necessary for the employee’s hands when the employee is wearing rubber insulating gloves with protectors or heavy-duty leather work gloves with a weight of at least 407 gm/m2 (12 oz/yd2) if the estimated incident energy is no more than 14 cal/cm2.

- Arc rated protection is not necessary for the employee’s feet when the employee is wearing heavy-duty work shoes or boots.

- Arc rated protection is not necessary for the employee’s head when the employee is wearing head protection meeting §1910.135 if the estimated incident energy is less than 9 cal/cm2 for exposures involving single-phase arcs in open air or 5 cal/cm2 for other exposures.

- PPE for the employee’s head may consist of head protection meeting §1910.135 and a face shield with a minimum arc rating of 8 cal/cm2 if the estimated incident energy exposure is less than 13 cal/cm2 for exposures involving single-phase arcs in open air or 9 cal/cm2 for other exposures.

- For exposures involving single-phase arcs in open air, the arc rating for the employee’s head and face protection may be 4 cal/cm2 less than the estimated incident energy.

As the potential incident energy increases, the protection level must also increase. It is the employer’s responsibility to assess the workplace, identify potential hazards, and provide adequate protection against the hazard.

Training the employee on how to properly use and care for PPE is also very important. An employee’s ability to identify electrical hazards, their knowledge of electrical equipment and its nominal voltage, and their understanding of when proper PPE is required will go a long way to ensuring they protect themselves from potential hazards.

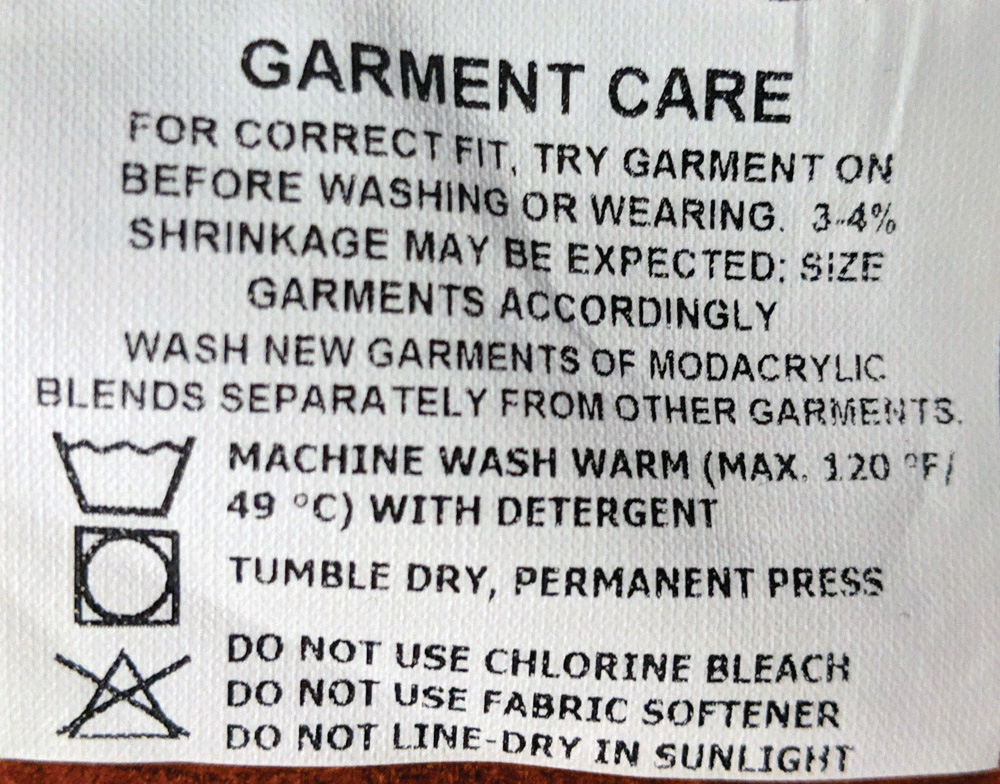

PPE that is worn, damaged, or deteriorated cannot adequately protect an employee from a potential hazard. Employees must learn to inspect all PPE prior to and after use. Guidelines for the inspection and care of arc rated clothing are found in ASTM F1449, Standard Guide for Industrial Laundering of Flame, Thermal, and Arc Resistant Clothing and ASTM F2757, Standard Guide for Home Laundering Care and Maintenance of Flame, Thermal, and Arc Resistant Clothing. Knowledge of these standards is required to manage arc resistant clothing, whether home laundered or commercially laundered.

Laundering Arc Rated Clothing

Training for employees on the care of arc rated clothing at home is also available. Many manufacturer websites provide videos, blogs, and instructional documents on how to properly maintain arc rated clothing.

Employees must also protect their feet by wearing heavy-duty work boots or shoes if they will be exposed to the hazard of flames or electrical arc. OSHA 29 CFR 1910.136(a)states:

Each affected employee shall wear protective footwear when working in areas where there is a danger of foot injuries due to falling or rolling objects, or objects piercing the sole, and where such employee’s feet are exposed to electrical hazards.

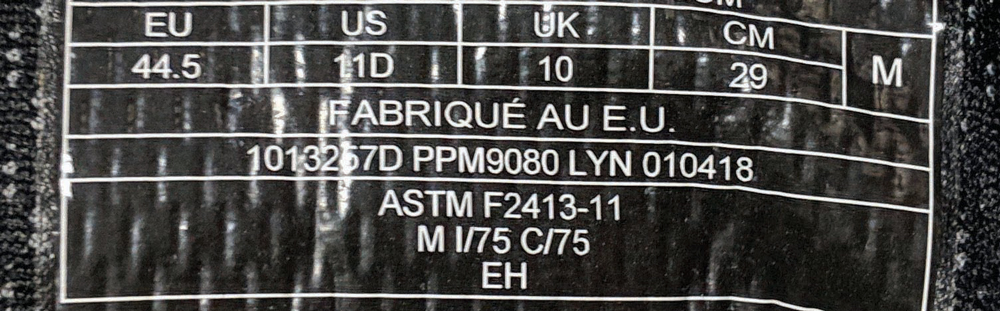

These conditions indicate to the employer that the boot or shoe would likely also need to be safety-toed and would be required to meet ASTM F2413, Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear.

Boots must also be rated for electrical hazards. EH-rated footwear is manufactured with non-conductive, electrical-shock-resistant soles and heels. The outsole is intended to provide a secondary source of shock-resistant protection to the wearer against the hazards from incidental contact with live electrical circuits, as well as electrically energized conductors, parts, or apparatus. Footwear must be capable of withstanding the application of 18,000 volts at 60 Hz for one minute with no current flow or leakage current in excess of one milliampere under dry conditions. If the potential is assessed to exceed this, protection such as rubber dielectric over-boots or shoes will be required.

Boot Certification

Proper care of footwear is very important. Exposed toe caps indicate a breakthrough in the leather of the boot and decreased arc and flame protection. Simple things such as broken, missing, or overly long laces can pose a simple trip hazard, which can cause serious injury. Wear in the sole of the boot exposes the employee to step potential during a ground fault. Spilled flammable materials can soak into a leather boot, possibly causing a flame hazard. Therefore, properly cleaning and maintaining protective boots and shoes is important.

Conclusion

Wearing the correct arc rated clothing and footwear protects the employee from many potential hazards, and making sure equipment is clean and well maintained is an important step to ensuring it adequately protects the wearer. To provide a safe and productive workplace, the employer must train employees to inspect, clean, and maintain protective equipment properly.

Paul Chamberlain has been the Safety Manager for American Electrical Testing Co., LLC since 2009. He has been in the safety field for the past 20 years, working for various companies and in various industries. Paul holds a BS in environmental health and safety from Massachusetts Maritime Academy.

Paul Chamberlain has been the Safety Manager for American Electrical Testing Co., LLC since 2009. He has been in the safety field for the past 20 years, working for various companies and in various industries. Paul holds a BS in environmental health and safety from Massachusetts Maritime Academy.