Many companies and people rely on NFPA 70E to guide them as they develop and implement electrical safe work practices. They look at a line or possibly a paragraph or two and believe they have the gist of the issue. Maybe, but they often misinterpret what they read or implement it incorrectly. Unfortunately, there’s a plethora of misleading or incorrect advice and information concerning the 70E. So what can you do?

Electrical Safety, 2018 Edition

by James R. White

First and foremost: Purchase a copy of the 70E and read it — several times. Have open discussions with others in your company who may have the same questions or may have the experience to be able to answer questions. Go to www.nfpa.org/70e and look through the committee comments, which explain why an action was taken on a public input or a public comment. The comments contain a lot of information, and it is not always easy reading.

Very little information is available other than the standard itself. NFPA publishes a handbook, but opposed to what people (including me at one time) assume, it is not the official interpretation of the 70E. It’s good, but it cannot be relied upon to always provide the best interpretation; sometimes, it’s just an opinion. Another source is a book I wrote, now in its third edition, that covers NFPA 70E and the OSHA regulations. It’s not really about the 70E, it’s about electrical safety. One could say some of it is opinion, but it is based on field experience.

NFPA 70E is currently open to revision for the next edition (the second draft meeting is in July 2019), so now is a good time to review it. First of all, 70E is a standard. By definition, a standard is not mandatory. OSHA regulations (which they call standards) are mandatory; they are the law of the land. However, you can be sure OSHA field safety compliance officers and attorneys refer to the 70E when they need more information. One compliance officer told me that OSHA is the “what;” the 70E is the “how.” More specifically, OSHA uses non-prescriptive language: It can’t tell us how to do things; there are just too any variables. The 70E, on the other hand, is prescriptive: It tells us what to wear and what is required to meet OSHA’s requirements. They complement each other well.

In all my years of working in the electrical trades (I’ve been doing this since 1969), I have never met someone who wanted to hurt themselves or others or wanted to damage equipment. However, I have met people who believe nothing bad will ever happen to them and who do things they have been trained or taught not to do.

So what does NFPA 70E state?

Article 100

Article 100 contains definitions. Some people view definitions as wasted space, but nothing could be further from the truth. To understand what something is saying, especially highly technical material, we must understand what is meant by certain words.

A great example is the definition for arc flash hazard. Informational Note No. 1 states, in part:

The likelihood of occurrence of an arc flash incident increases when energized electrical conductors or circuit parts are exposed or when they are within equipment in a guarded or enclosed condition, provided a person is interacting with the equipment in such a manner that could cause an electric arc.

The word “interacting” is not defined, but the same informational note previously referred to racking circuit breakers and installing or removing motor control buckets — any task that involves sliding equipment on or off an energized bus.

Article 105

In the next edition, Article 105 is due to pick up quite a bit of information currently located in other articles. The 70E committee is always trying to make the 70E easier to use and understand, and making the information flow better is one way to do that. During the past three cycles, we spent a great deal of effort reorganizing articles so the information is easier to use, so we will probably move Article 105.4 to Article 110.1. Maybe — first-draft actions sometimes get trashed when we come back to them in the second draft.

Article 110

With a three-year review cycle, the committee can respond to changes in technology, definitions, or work methods, and quite a few changes are scheduled for Article 110 if they all stay in place.

- New Informational Note No. 2 might be added to Article 110.1 to define that an electrically safe work condition is elimination of the hazard. This was done to clarify the committee’s stance on elimination, since some were a bit confused.

- Article 120.2(A) will be relocated to Article 110.1. Parts of Article 120 and Article 130 will be added, and then the entire article would be renumbered.

- One of the more notable proposals that passed first draft is to state in an informational note that classroom training can include interactive electronic or web-based training components. Such training must be interactive, not isolated. The committee wants this new note to allow advances in technology without compromising the training people receive. This would be especially beneficial for NETA member companies, as technicians often get scheduled for training, but then a job comes up unexpectedly. Guess which one wins.

Article 120

Article 120 has not changed very much, except Article 120.2(A) was moved to Article 110.

Article 130

A number of changes to Article 130 are proposed. Please note these are only proposed changes, and things may change with the second draft meeting.

- Article 130.1 was added to clarify the steps to be taken to protect employees from electrical hazards. This includes any work on circuits above 50 V, the requirement to be a qualified person, completing an energized electrical work permit, and performing a risk assessment. There’s nothing new, but it does put all the major requirements up front within Article 130.

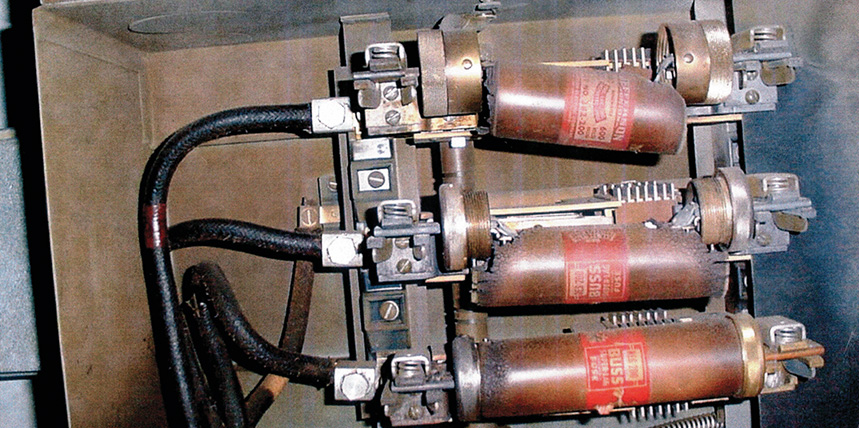

- A new section on estimating the likelihood and severity of occurrence of injury or damage to health is being added. Things to consider are the design of the equipment, its operating condition, and the condition of maintenance. Equipment condition and maintenance (or lack thereof) has been an on-going committee concern for the last three cycles. Electrical equipment is often not maintained properly to save money, which it will do in the short term, but it can cost more if it fails.

- An unqualified person entering a limited approach boundary must now be continuously escorted by a qualified person. This has been true before, but that qualified person now must have no other duties. If he/she is going to escort, they must escort continuously and not be distracted.

- A new task is being added to Table 130.5(C) Estimate of the Likelihood of Occurrence of an Arc Flash Incident for ac and dc Systems: Operation of a CB or switch the first time after installation or completion of work or maintenance in the equipment. The committee considered this task at length. When is equipment most likely to fail? Regardless of equipment condition, there is an increased likelihood of occurrence the first time, and additional protective measures must be implemented. It’s worth emphasizing that these additional protective measures will probably include the use of PPE, but may also include any of the hierarchy of risk control measures. The tasks involved with arc-resistant switchgear also changed; they now apply to all arc-resistant electrical equipment, not just switchgear. This reflects starter buckets and other equipment coming onto the market.

- Table 130.5(G) was cleaned up a bit and now will include high-visibility apparel. It clarifies that incident energy for this table includes 1.2 cal/cm2 up to and including 12 cal/cm2.

- Another new note states that footwear other than leather can be worn if it has been tested and won’t ignite, melt, or drip. This is to allow newer technologies to be used in the workplace.

- In the past, Section 130.7(C) Personal Protective Equipment (PPE) stated that PPE must be worn inside the arc flash boundary. This is still true, but a new informational note points out that PPE can be worn outside the arc flash boundary to reduce the likelihood of injury from molten metal, debris, or sound. Hazards from an electric arc can cross the arc flash boundary, and must be considered.

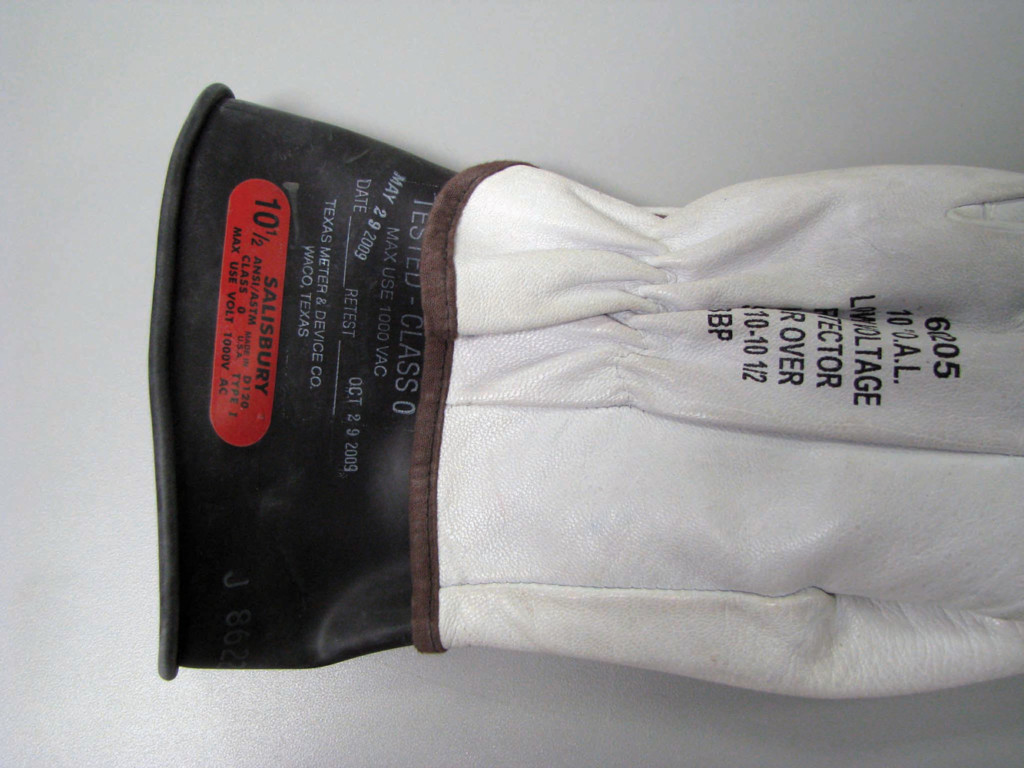

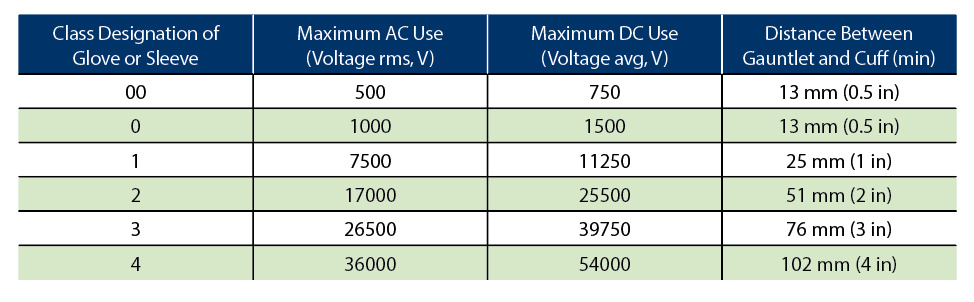

- The subject of rubber insulating gloves came up again this cycle, and the committee specified that the cuff of the protector glove must be shorter than the rolled top of the cuff of the insulting glove by at least the distance provided in Table 130.7(C)(7)(a) (Table 1). Many workers, especially new workers or those who don’t often do energized electrical work (that should be most of us) don’t realize that a certain distance is needed to prevent voltage creep or flash over.

Adequate Distance between Protector Cuff and Glove

Inadequate Distance between Protector Cuff and Glove

Table 1: Proposed Table 130.7(C)(7)(a) Maximum Use Voltage for Rubber Insulating Gloves

Note that the ASTM F18 committee just voted to allow the design and construction of non-leather protector gloves. In a recent ASTM F18 committee meeting, it was found that dc testing always found any problem with rubber insulating equipment, but ac testing sometimes did not. That may make a difference is how gloves are tested.

- A new informational note points out why following the manufacturer’s instructions is so important with arc-rated clothing. Contaminants, such as metal particles or hydrocarbons, can be in the cloth. This could cause the arc-rated clothing to fail during an arc. Disease-carrying contaminants may also be in the cloth, which carries its own risk. Regular cleaning should be performed on all safety equipment. It is pretty nasty to wear dirty or sweat-soaked arc-rated clothing.

- Table 130.7(C)(14) Informational Note: Standards For Personal Protective Equipment has been updated with the new standard numbers and the new name of the standard if it has been changed.

- Section 130.7(C)(15) covers the arc flash category method (table method) of selecting arc-rated PPE. It now states that the highest estimate of fault clearing time should be based on the line or load side of the overcurrent protective device, whichever is greater. This is to clarify that the line side is not always the greater of the two.

- Another new statement is that the 70E requirements are the minimum requirements. Many companies believe that if they meet the 70E requirements, that is all that is needed — but it is not. More than the minimum is often required. The 70E can’t specify what is needed in each and every situation, which is why risk assessments for shock and arc flash must be completed.

- Table 130.7(C)(15)(a) Arc-Flash PPE Categories for Alternating Current (ac) Systems includes a new series of tasks related to arc resistant equipment. This includes arc resistant motor control centers, 600 V class switchgear, 1 kV through 15 kV switchgear, and enclosed interrupter switchgear. It also states that the specification for arc flash boundary and PPE category is not applicable based on the doors being closed. If the doors are open, the user will now be directed to the non-arc resistant equipment sections of the table. This should help clarify when arc resistant equipment really has arc resistant qualities and when it does not.

- No changes are proposed for Table 130.7(C)(15)(b) Arc-Flash PPE Categories for Direct Current (dc) Systems.

- In Table 130.7(C)(15)(c) Personal Protective Equipment (PPE), high-visibility apparel and arc-rated gloves or rubber insulating gloves with leather protectors were added to all categories of PPE. A note to the table also states that rubber insulating gloves with leather protector gloves provide arc flash protection in addition to shock protection. It must be emphasized that arc resistant gloves provide zero shock protection.

- Tools or handling equipment used within the restricted approach boundary must be insulated. That means they meet the ASTM F1505 standard. The 70E doesn’t say this, but if you want to see your children grow up, that would be my advice.

- Section 130.7(D)(f) Protective Shields has been rewritten and renamed Protective Barriers to clarify what it is speaking to. Its requirements and intent should be much clearer.

- Table 130.7(G) Informational Note: Standards on Other Protective Equipment has been updated with ASTM F3272, Standard Guide for Selection, Care, and Use of Arc Protective Blankets.

Chapter 2

In Chapter 2, Section 250.3(B), temporary grounding equipment will have to be tested at intervals not to exceed three years. In the past, there was no guidance on testing of grounds; this provides minimum requirements.

Conclusion

The purpose of this article is to make NETA member companies aware of changes that were proposed and accepted during the first draft meeting; it does not try to cover all changes. A lot happens during the second draft meeting, so NETA members shouldn’t get too excited and make changes right away. However, any member who thinks of an improvement or doesn’t approve of something should contact me and let your voice be heard. Ron Widup and I are on the 70E committee to express NETA’s wants and needs, and we both try to do so. It would be nice to hear from you.

Ron Widup and Jim White are NETA’s representatives to NFPA Technical Committee 70E, Electrical Safety Requirements for Employee Workplaces. Both gentlemen are employed by Shermco Industries in Dallas, Texas, a NETA Accredited Company.

Ron Widup is CEO of Shermco Industries and has been with the company since 1983. He is a member of the Technical Committee on NFPA 70E, Standard for Electrical Safety in the Workplace; a Principal Member of the National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; and a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation. Ron is also a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and a member of the NETA Board of Directors and Standards Review Council. He is Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron is a Journeyman Electrician in Texas, a NETA Level 4 Senior Technician, and an NFPA Certified Electrical Safety Compliance Professional.

Ron Widup is CEO of Shermco Industries and has been with the company since 1983. He is a member of the Technical Committee on NFPA 70E, Standard for Electrical Safety in the Workplace; a Principal Member of the National Electrical Code (NFPA 70) Code Panel 11; a Principal Member of the Technical Committee on NFPA 790, Standard for Competency of Third-Party Evaluation Bodies; and a Principal Member of the Technical Committee on NFPA 791, Recommended Practice and Procedures for Unlabeled Electrical Equipment Evaluation. Ron is also a member of the Technical Committee on NFPA 70B, Recommended Practice for Electrical Equipment Maintenance, and a member of the NETA Board of Directors and Standards Review Council. He is Vice Chair for IEEE Std. 3007.3, Recommended Practice for Electrical Safety in Industrial and Commercial Power Systems. Ron is a Journeyman Electrician in Texas, a NETA Level 4 Senior Technician, and an NFPA Certified Electrical Safety Compliance Professional.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Standard for Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.

James (Jim) R. White, Vice President of Training Services, has worked for Shermco Industries since 2001. He is a NFPA Certified Electrical Safety Compliance Professional and a NETA Level 4 Senior Technician. Jim is NETA’s principal member on NFPA Technical Committee NFPA 70E®, Standard for Electrical Safety in the Workplace; NETA’s principal representative on National Electrical Code® Code-Making Panel (CMP) 13; and represents NETA on ASTM International Technical Committee F18, Electrical Protective Equipment for Workers. Jim is Shermco Industries’ principal member on NFPA Technical Committee for NFPA 70B, Recommended Practice for Electrical Equipment Maintenance and represents AWEA on the ANSI/ISEA Standard 203, Secondary Single-Use Flame Resistant Protective Clothing for Use Over Primary Flame Resistant Protective Clothing. An IEEE Senior Member, Jim was Chairman of the IEEE Electrical Safety Workshop in 2008 and is currently Vice Chair for the IEEE IAS/PCIC Safety Subcommittee.