This is year two for the fifth edition of the CSA Z462, Workplace electrical safety Standard. Are you aware of the changes and updates that could impact your electrical safety program? Have you provided arc flash and shock training to your qualified persons on the new edition? Do you still have questions that need clarification?

We marked the first anniversary of the 2021 Edition of the CSA Z462, Workplace electrical safety Standard on January 1, 2021. Canadian companies must ensure they are aware of and follow up on this latest edition of CSA Z462 to maintain diligence; measure performance of established policies, practices, and procedures; and look for opportunities for improvement (e.g., PLAN-DO-CHECK-ACT). This is also a mandatory requirement of CSA Z462 Clause 4.1.7.12 Auditing.

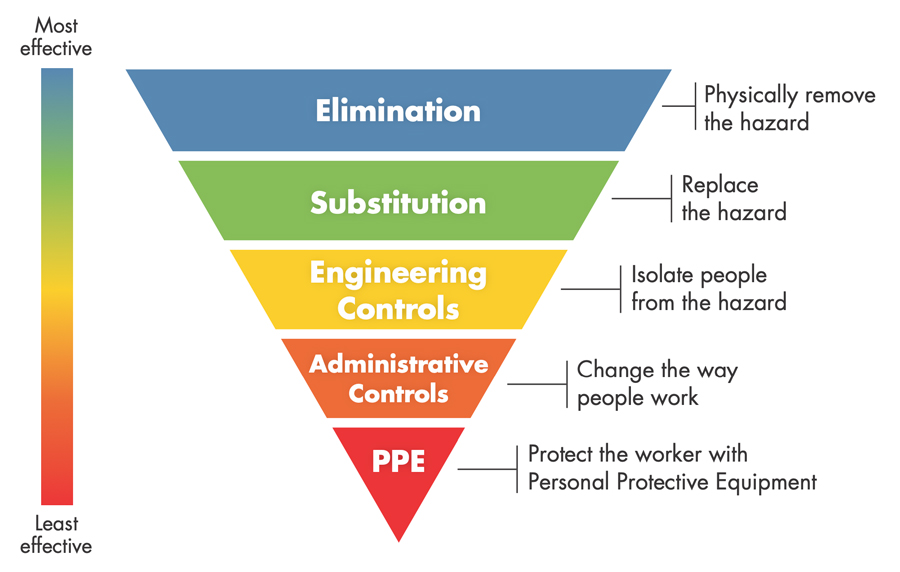

2020 and 2021 were challenging years for us all, but it is important to ensure we continue our journey and mission to eliminate exposure to electrical hazards by implementing the hierarchy of risk control methods (Figure 1) to reduce risk to as low as reasonably practical. We need to “Get it Right!”

Figure 1: Hierarchy of Risk Control Methods

This article provides a year in review for 2021 and CSA Z462 in Canada, highlighting what I see, hear, and experience when working with industry to interpret and apply CSA Z462 while developing and implementing a compliant electrical safety program, completing external electrical safety audits, and providing arc flash and shock training.

MYTHS AND MISINFORMATION

Throughout 2021, I was confronted again with responding to the following questions or comments:

- Is it against the law to perform energized electrical work?

- We have a policy and we do not perform “live” work.

- I will not execute a work task when the incident energy is greater than 40.0 cal/cm2. It is “dangerous,” risk is too high to complete that work task, and “no PPE exists.”

- Arc flash PPE is specified with an arc flash PPE category number or Level A, B, C, D and E.

- Arc flash hazard incident energy analysis reports are still issued by PEng/PE Electrical Engineers with misinformation. Documentation of the basis of the analysis performed is lacking. They are conservative or have incorrect parameter selections, and arc flash and shock equipment labels are not compliant to CSA Z462 and ANSI Z535.

- Do we need full-body arc flash PPE to operate energized electrical equipment? The trainer said the electrical equipment will fail and create an arc flash.

Sir Francis Bacon is credited with saying, “Knowledge is power!” We must ensure that compliant electrical safety programs are developed, implemented, and audited. In turn, this will ensure that myths and misinformation is effectively managed and answers are provided through the electrical safety program using tools such as the risk assessment procedure.

ELECTRIC SHOCK SEQUELA

In 2021, I continued to dialogue and follow up with John Knoll from Edmonton, Alberta, on electrical shock sequelae. John is a Journeyperson Electrician, CME, and Professional Electrical Contractor (PEC), now retired due to electrical shock sequelae, which is the potential long-term physiological, neurological, and physical effects of receiving multiple electrical shocks while working.

John is now a subject matter expert and spokesperson advocating that we need to address the electric shock hazard in the workplace so that workers do not receive the shocks that cause potential fatal immediate effects as well as potential long-term effects of electrical shock sequelae. I have commented many times that we all must change the narrative from arc flash to ensuring both arc flash and shock are identified and discussed. In fact, electric shock hazards need priority attention because electrical incident statistics are a lagging indicator to advise us of the continued high frequency of fatal injury (e.g., electrocution).

ARC FLASH AND SHOCK PPE AND TOOL INNOVATIONS

In 2021, innovations in arc flash PPE and separately new hand tools are helping eliminating exposure to arc flash. For example, Oberon Company developed an escape-strap option for their arc flash suit jacket in 2020 and in 2021 added an escape strap vest (https://oberoncompany.com/escape-strap/) that can be worn over everyday task-wear arc flash PPE. The escape strap can be used to release a worker who might be experiencing a shock or has been exposed to an arc flash. It allows the first responder to stand back 10 feet or more and use the escape strap to pull the worker away from the electrical equipment to a safe area to apply first aid/CPR.

Also in 2021, Amidyne Solutions (www.amidyne.ca) released their Extend-a-Rack manual racking tool that uses a telescopic hot stick and coupling to engage with the power circuit breaker to rack it in or out. In most cases, this will place the qualified person outside the arc flash boundary distance, where full-body arc flash PPE would not be required. This is a more affordable solution than a remote racking system and is easy to transport and use.

Amidyne Extend-a-Rack Manual Racking Tool

ELECTRICAL NEAR MISSES, HITS, AND INCIDENTS

Unfortunately, in 2021, I was involved in providing support to several electrical incident investigations. This is a reminder that near misses/hits are occurring, and in some improbable cases, energized electrical equipment is failing without interaction.

Following the PLAN-DO-CHECK-ACT philosophy, audits and incident investigations need to be perceived as opportunities for improvement. Was a documented, implemented, and audited electrical safety program in place? Why was the policy, practice, or procedure not followed by the qualified person? When did the qualified person last receive compliant arc flash and shock training? What was the root cause of the abnormal arcing fault without interaction, and how can we predict it or prevent it from happening again? Was human performance and human error the root cause? Was the appropriate arc flash and shock PPE worn and used?

Some of the reasons these incidents occur relate to human performance and human error precursors:

- Time pressure, rushing to complete the job and work task(s)

- Simultaneous or multiple work tasks

- Complacency

- Lack of policies and practices

- Unfamiliar or first time performing a work task

- Lack of knowledge

- Lack of experience

- Illness or fatigue

- Stress

WHAT IS HAPPENING IN 2022?

In March 2022, I presented on electrical shock sequelae at the NETA PowerTest Conference in Denver, Colorado, and at the IEEE Electrical Safety Workshop (ESW) in Jacksonville, Florida. John Knoll accompanied me to tell attendees about his experience with electrical shock sequelae. I also attended the IEEE ESTMP Conference in Edmonton, Alberta, where I presented on CSA Z462 and its relationship to IEEE 1584 as part of a panel session.

In May 2022, the first formal and detailed CSA Z462 Technical Committee meetings were held to review submissions for changes, improvements, and additions. Those changes will be reviewed and voted on and will be the basis for the 2024 Edition of CSA Z462. Yes, we are still several years away, but the review meetings and review cycle take time.

The CSA Z463, Maintenance of electrical systems Standard Technical Committee will also meet to review the status of the 2018 Edition. CSA Z463 is not on the same cycle frequency as CSA Z462. I am not sure when we may publish an update. If you have ideas for changes, improvements, or updates, please contact CSA or let me know, and I will bring them forward to the CSA Project Manager.

Terry Becker, PEng, CESCP, IEEE Senior Member is an Electrical Safety Specialist and Management Consultant at TW Becker Electrical Safety Consulting Inc. He is the first past Vice-Chair of the CSA Z462, Workplace electrical safety Standard Technical Committee and currently a Voting Member and Clause 4.1 and Annexes Working Group Leader. Terry is also a Voting Member on the CSA Z463, Maintenance of electrical systems Standard and a Voting Member on the IEEE Std. 1584, Guide for Performing for Arc-Flash Hazard Calculations technical committees. Terry has presented at conferences and workshops on electrical safety in Canada, the United States, India, and Australia. He is a Professional Engineer in the Provinces of BC, AB, SK, MN, and ON. If you are interested in discussing the information presented in this article do not hesitate to contact me at terry.becker@twbesc.ca or 587-433-3777.

Terry Becker, PEng, CESCP, IEEE Senior Member is an Electrical Safety Specialist and Management Consultant at TW Becker Electrical Safety Consulting Inc. He is the first past Vice-Chair of the CSA Z462, Workplace electrical safety Standard Technical Committee and currently a Voting Member and Clause 4.1 and Annexes Working Group Leader. Terry is also a Voting Member on the CSA Z463, Maintenance of electrical systems Standard and a Voting Member on the IEEE Std. 1584, Guide for Performing for Arc-Flash Hazard Calculations technical committees. Terry has presented at conferences and workshops on electrical safety in Canada, the United States, India, and Australia. He is a Professional Engineer in the Provinces of BC, AB, SK, MN, and ON. If you are interested in discussing the information presented in this article do not hesitate to contact me at terry.becker@twbesc.ca or 587-433-3777.